Preparation of supported platinum group metal monatomic catalyst, and applications of supported platinum group metal monatomic catalyst in deoxidation reaction

A platinum group metal and catalyst technology, which is applied in the field of preparation of supported platinum group metal single-atom catalysts, can solve problems such as unsuccessful application, and achieve the effects of high utilization rate, good deoxidation depth and high intrinsic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

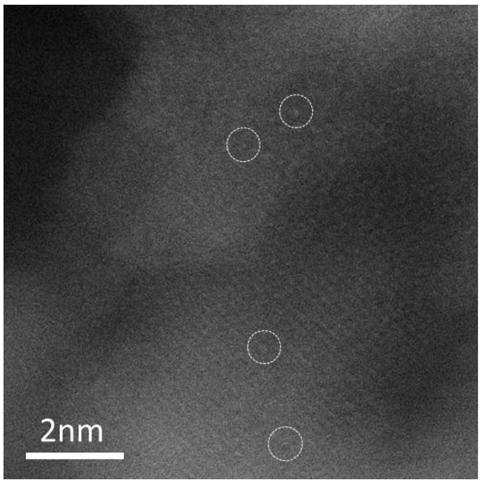

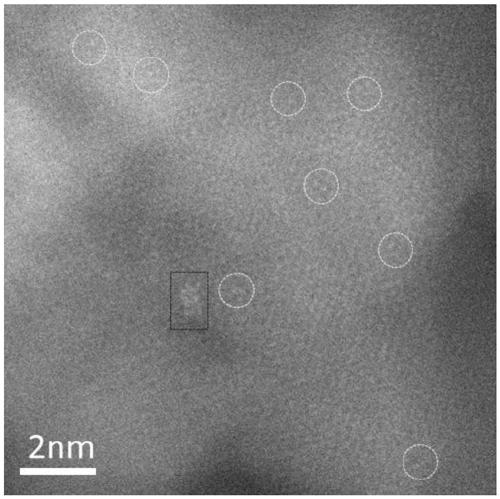

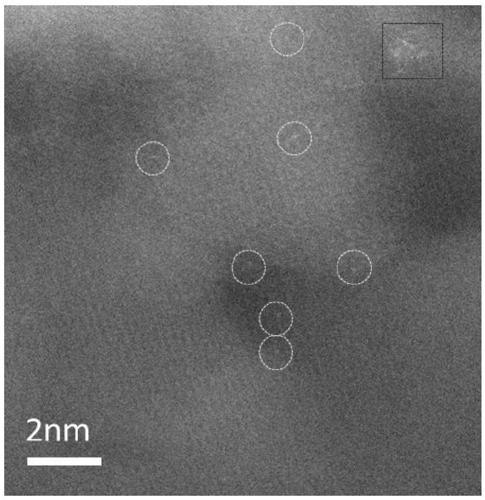

Image

Examples

Embodiment 1

[0034] 3.0mg PdCl 2 Dissolve completely in 15 mL of deionized water with vigorous stirring. Pour 5g of spherical alumina carrier into the precursor solution. After the carrier is saturated, heat it at 80°C until the water is completely volatilized while stirring continuously. The obtained Pd-adsorbed alumina carrier was dried in an oven at 80° C. for 10 h, and then taken out. Reduction with hydrogen at 50 °C for 30 min. After natural cooling, the sample was taken out to obtain a spherical alumina-supported 0.036wt% monoatomic palladium catalyst. The 0.036wt% monoatomic palladium catalyst of 1.5g spherical alumina loading is packed in the reaction tube, open feed gas, O 2 Content: 0.3vol%; H 2 Content: 99.7vol%; Adjust volume space velocity: 7000h -1 . Set the reaction temperature as room temperature, the reaction pressure as normal pressure, and the oxygen concentration in the tail gas as 0.05ppm.

Embodiment 2

[0039] 5.5mg Pd(NO 3 ) 2 Dissolve completely in 10 mL of deionized water with vigorous stirring. Pour 5g of manganese oxide powder carrier into the precursor solution. After the carrier is saturated, heat it at 70°C until the water is completely volatilized while stirring continuously. The obtained Pd-adsorbed manganese oxide support was dried in an oven at 150° C. for 2 h, and then taken out. Reduction with hydrogen at 20°C for 10 min. After natural cooling, the sample was taken out to obtain a catalyst in which 0.051wt%>50% of Pd supported on manganese oxide existed in the form of single atoms. The 0.051wt%>50% Pd that 2.0g manganese oxide load is present is packed in the reaction tube with the catalyst of monoatomic form, open feed gas, O 2 Content: 0.1vol%; H 2 Content: 99.9vol%; Adjust volume space velocity: 4500h -1 . Set the reaction temperature at 80° C., the reaction pressure at 1.5 MPa, and the oxygen concentration in the tail gas at 0.53 ppm.

Embodiment 3

[0041] 11.0mg Pd(OAc) 2 Dissolve completely in 5 mL of deionized water with vigorous stirring. Pour 5g of molecular sieve powder carrier into the precursor solution. After the carrier is saturated, heat it at 80°C until the water is completely volatilized while stirring continuously. The obtained Pd-adsorbed molecular sieve carrier was dried in an oven at 300° C. for 4 h, and then taken out. Reduction with hydrogen at 80°C for 20 min. After natural cooling, the sample is taken out to obtain a catalyst in which 0.10wt%>50% of Pd supported by molecular sieves exists in the form of single atoms. The 0.10wt%>50% Pd that 1.5g molecular sieve load exists is packed in the reaction tube with the catalyst of monatomic form, open feed gas, O 2 Content: 5vol%; H 2 Content: 50vol%; balance gas is helium; volumetric space velocity adjustment: 15000h -1 . Set the reaction temperature at 300° C., the reaction pressure at 0.5 MPa, and the oxygen concentration in the tail gas at 0.08 ppm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com