Grinding preparation method of copper (I)-bromine hybrid fluorescent materials

A fluorescent material and mixed grinding technology, applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of cumbersome reaction steps, difficulty in finding solvents, production of divalent copper by-products, etc., and achieve simple preparation methods and stable fluorescence Good effect with great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

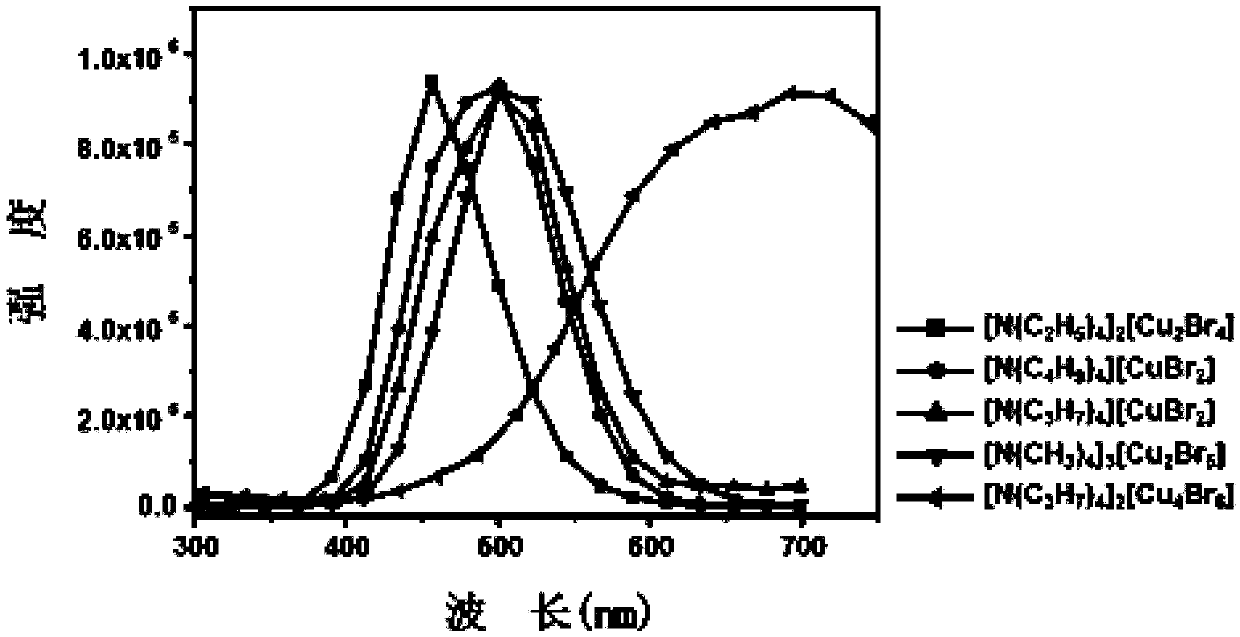

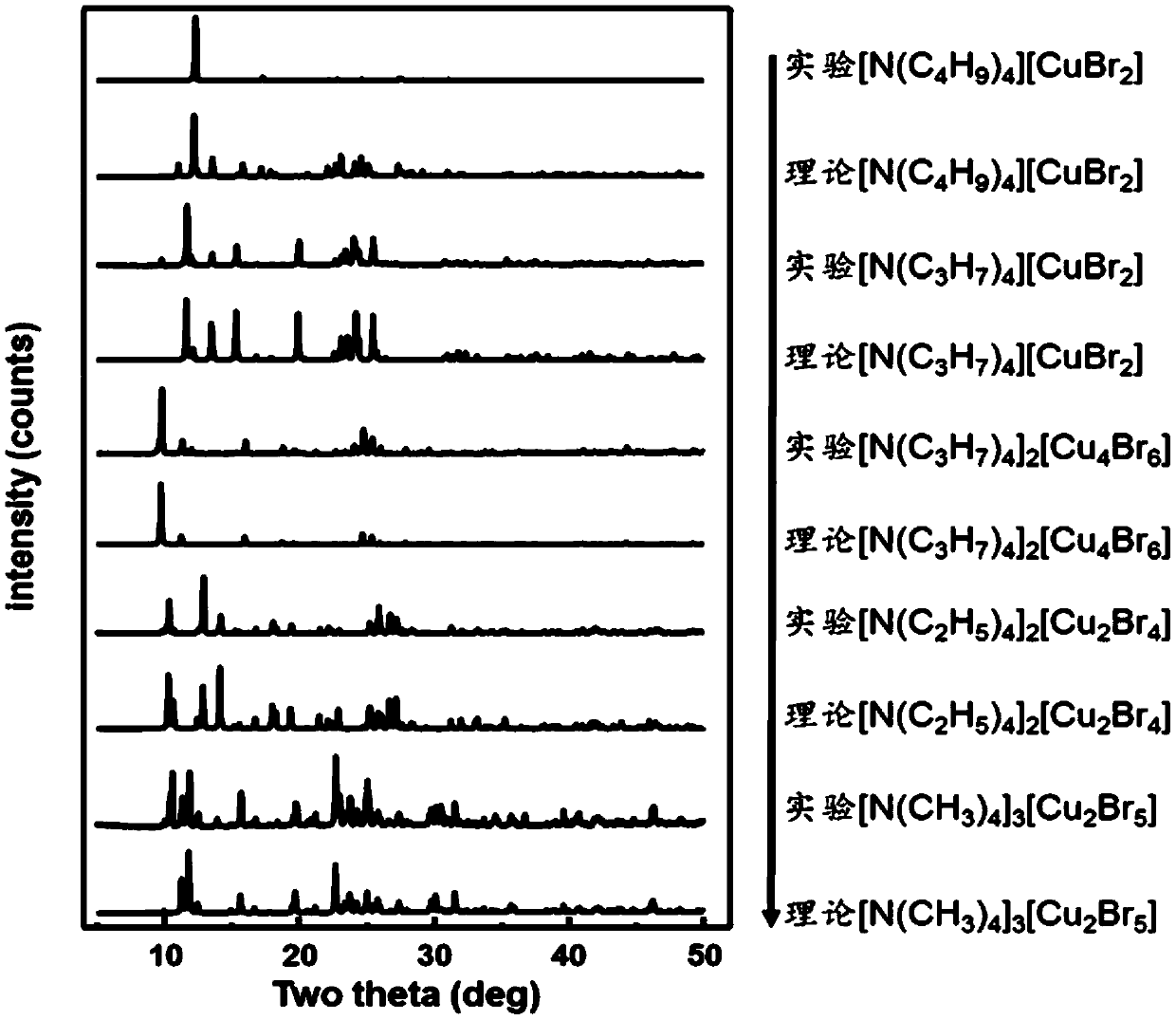

[0020] Weigh 0.308 g of tetramethylammonium bromide and 0.572 g of cuprous bromide, place them in a mortar, expose to air at room temperature 25° C., and grind for 30 min. The mixture after the grinding reaction was dissolved in 20ml of boiling isopropanol, filtered while hot, and the filtrate was allowed to stand and cool to precipitate a solid, and the resulting solid was vacuum-dried to obtain the product [N(CH 3 ) 4 ] 3 [Cu 2 Br 5 ]. The obtained [N(CH 3 ) 4 ] 3 [Cu 2 Br 5 ] clusters emit yellow-green fluorescence under 254nm ultraviolet excitation, and the maximum emission wavelength is around 510nm. The fluorescence spectrum data are as follows: figure 1 shown. Its X-ray powder diffraction pattern of the prepared copper (I) halogen cluster compound is as follows figure 2 As shown, the positions of the diffraction peaks are consistent with the theoretical simulation spectrum.

Embodiment 2

[0022] Weigh 0.82 g of tetraethylammonium bromide and 0.28 g of cuprous bromide, place them in a mortar, expose to air at room temperature 25°C, and grind for 30 min. The mixture after the grinding reaction was dissolved in 20ml of boiling ethanol, filtered while it was hot, the filtrate was left to stand and cooled to precipitate a solid, and the gained solid was dried in vacuo to obtain the product [N(C 2 h 5 ) 4 ] 2 [Cu 2 Br 4 ]. The obtained [N(C 2 h 5 ) 4 ] 2 [Cu 2 Br 4 ] clusters emit blue fluorescence under 254nm ultraviolet excitation, and the maximum emission wavelength is around 460nm. The fluorescence spectrum data are as follows: figure 1 shown. Its X-ray powder diffraction pattern of the prepared copper (I) halogen cluster compound is as follows figure 2 As shown, the positions of the diffraction peaks are consistent with the theoretical simulation spectrum.

Embodiment 3

[0024] Weigh 0.80 g of tetrapropylammonium bromide and 0.28 g of cuprous bromide, place them in a mortar, expose them to air at room temperature 25° C., and grind for 30 min. The mixture after the grinding reaction was dissolved in 20ml of boiling ethanol, filtered while it was hot, the filtrate was left to stand and cooled to precipitate a solid, and the gained solid was dried in vacuo to obtain the product [N(C 3 h 7 ) 4 ] 2 [Cu 4 Br 6 ]. The obtained [N(C 3 h 7 ) 4 ] 2 [Cu 4 Br 6 ] clusters emit orange-red fluorescence under 254nm ultraviolet excitation, and the maximum emission wavelength is around 660nm. The fluorescence spectrum data are as follows: figure 1 shown. Its X-ray powder diffraction pattern of the prepared copper (I) halogen cluster compound is as follows figure 2 As shown, the positions of the diffraction peaks are consistent with the theoretical simulation spectrum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com