Ester hydrogenation catalyst and preparation method and application thereof

A technology for hydrogenation of catalysts and esters, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the preparation of hydroxyl compounds. Hydrogen-to-ester ratio, reduction of equipment investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

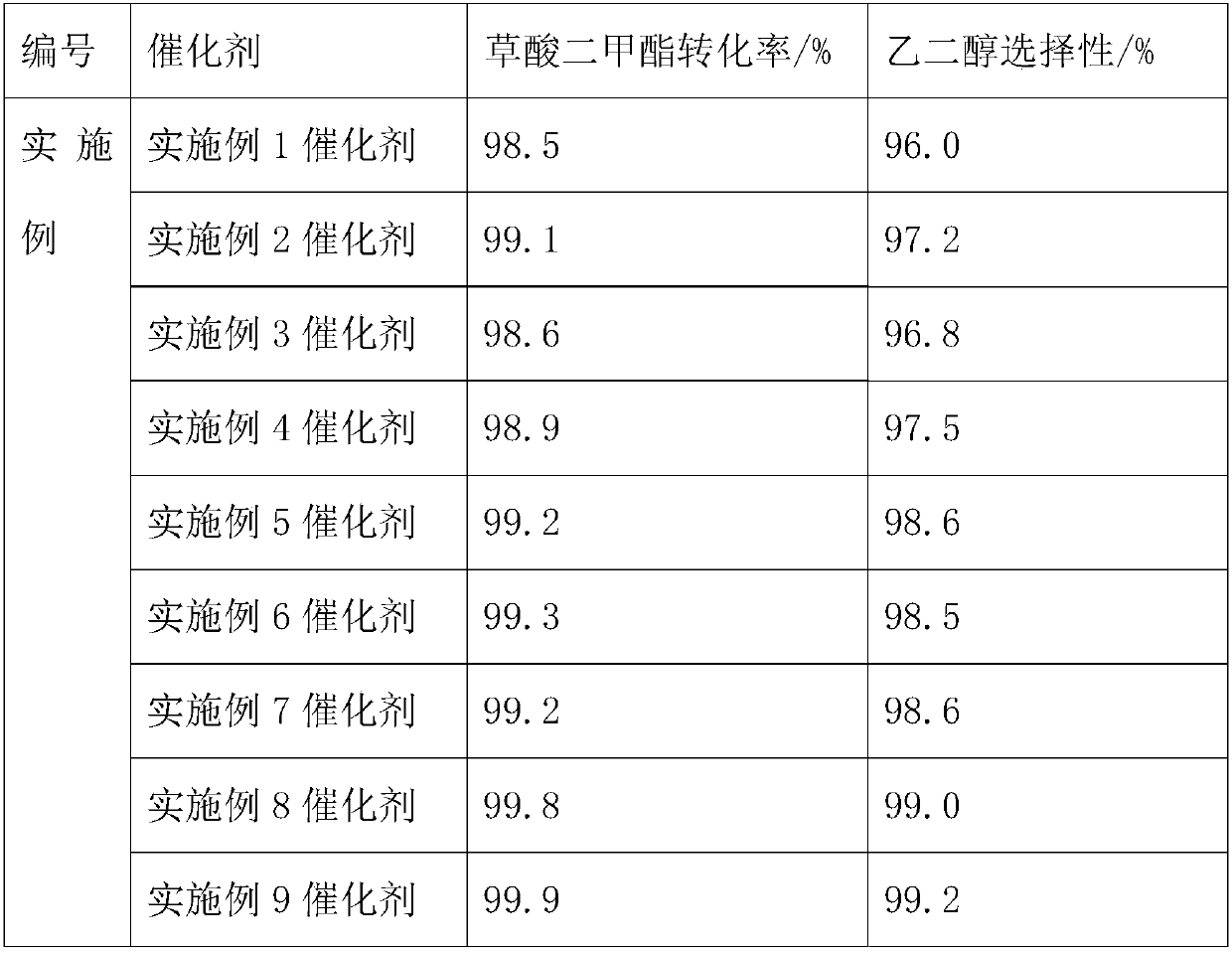

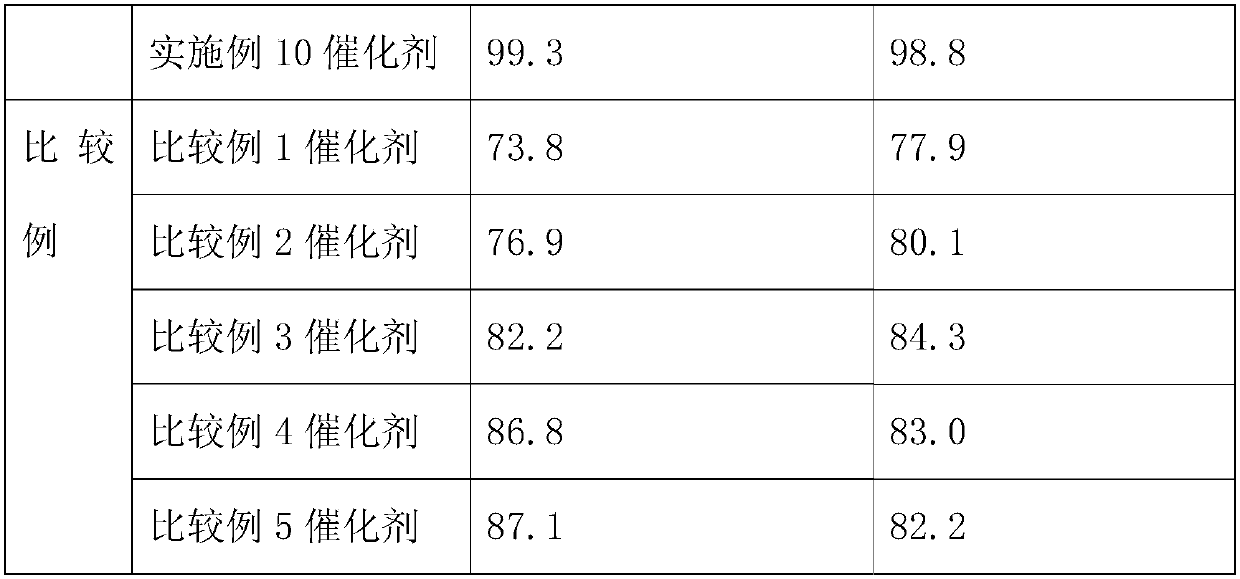

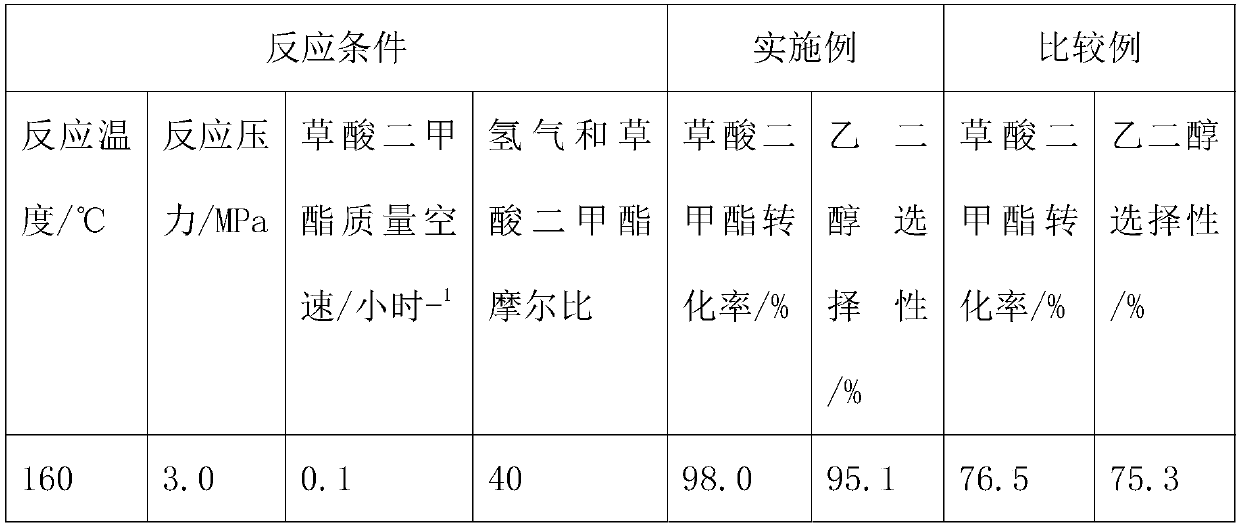

Examples

Embodiment 1

[0034] Take 500mL of a solution containing 0.20mol / L copper nitrate as solution I, add 14 grams of silicon dioxide to solution I under stirring to obtain slurry II, and then add 1.00mol / L sodium carbonate as a precipitating agent to slurry III In the process, the pH at the end point was controlled to be 7, aged at 60°C for 36 hours, and then the slurry was filtered and washed, and the obtained filter cake was dried at 150°C for 10 hours, roasted at 400°C for 5 hours, and 20 mL of 0.005 mol / L PdCl 2 And 0.010mol / L boric acid solution was added to the calcined catalyst and impregnated for 24 hours, then an excess of liquid phase reducing agent KBH was added 4 The solution reduces it, and the end point of the reduction reaction is pH 8. Washing, drying and pressing into tablets is the oxalate hydrogenation catalyst. Its composition is tested by ICP: 31.2 parts of copper, 0.1 part of Pd-B alloy and 68.7 parts of silicon dioxide.

Embodiment 2

[0036] Take 500mL of a solution containing 0.10mol / L copper nitrate as solution I, add 8.00g of silicon dioxide to solution I under stirring to obtain slurry II, and then add 0.50mol / L sodium carbonate as a precipitating agent to slurry III In the process, the pH at the end point is controlled to be 6, aged at 50°C for 48 hours, and then the slurry is filtered and washed, and the obtained filter cake is dried at 120°C for 24 hours, roasted at 500°C for 4 hours, and 50 mL of 0.01mol / L PdCl 2 And 0.03mol / L boric acid solution was added to the calcined catalyst and impregnated for 24 hours, then an excess of liquid phase reducing agent KBH was added 4 The solution reduces it, and the end point of the reduction reaction is pH 7. Washing, drying and pressing into tablets is the oxalate hydrogenation catalyst. Its composition is tested by ICP: 28.1 parts of copper, 1.0 parts of Pd-B alloy and 70.9 parts of silicon dioxide.

Embodiment 3

[0038] Use 1000mL of a solution containing 0.08mol / L copper nitrate as solution I, add 4.8 grams of silicon dioxide to solution I under stirring to obtain slurry II, and then add 0.50mol / L sodium carbonate as a precipitating agent to slurry III In the process, the pH at the end point is controlled to be 6, aged at 120°C for 1 hour, then the slurry is filtered and washed, the obtained filter cake is dried at 100°C for 36 hours, roasted at 600°C for 1 hour, and 30mL of 0.001mol / L PdCl 2 And 0.03mol / L zirconium nitrate solution is added to the calcined catalyst and impregnated for 24 hours, then add excess liquid phase reducing agent KBH 4 The solution reduces it, and the end point of the reduction reaction is pH 5. Washing, drying and pressing into tablets is the oxalate hydrogenation catalyst. Its composition is tested by ICP: 11.5 parts of copper, 2.0 parts of Pd-Zr alloy and 86.5 parts of silicon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com