Metal coordination triazine polyionic liquid catalyst as well as preparation method and application thereof

A polyionic liquid and metal coordination technology, which is applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of difficult recovery of catalysts and low product yields , to achieve the effect of increasing industrial production capacity, simplifying process flow, reducing equipment investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

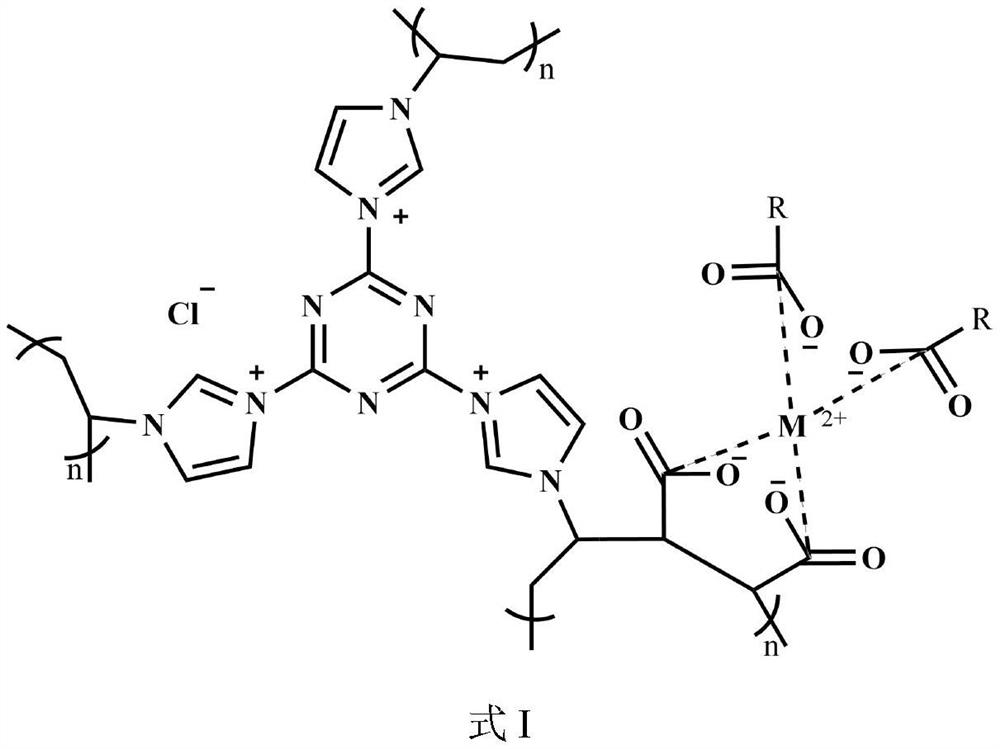

[0024] Preparation of Manganese Acetate Coordinated Triazine Polyionic Liquid

[0025]

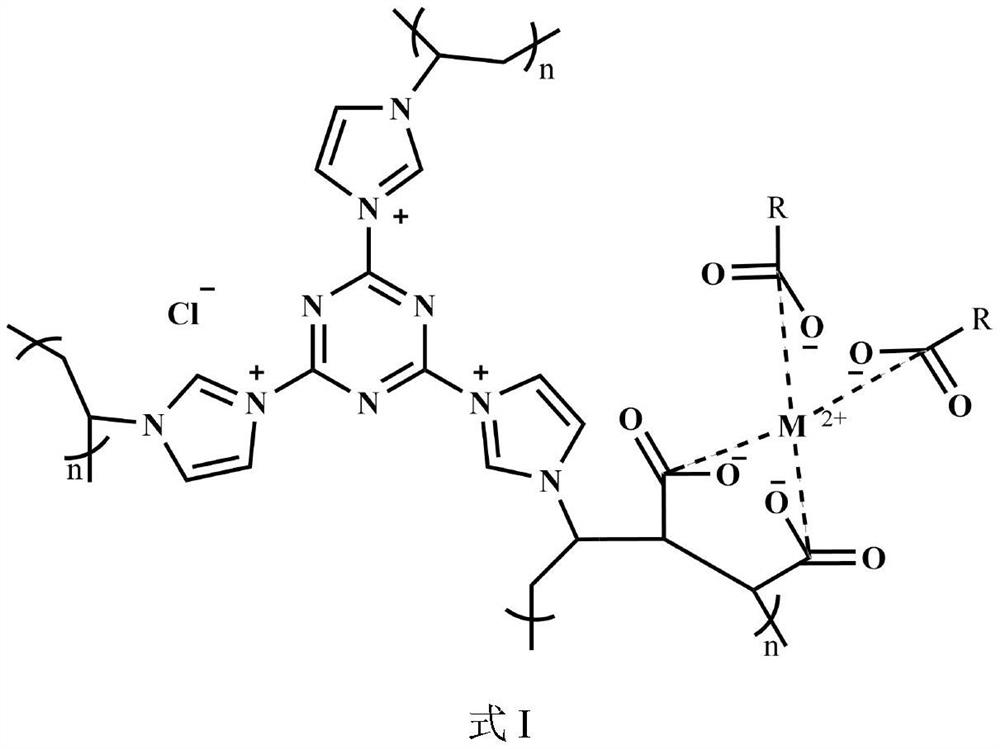

[0026] Step 1. Add 10mmol cyanuric chloride to 50mL dimethyl sulfoxide and stir until completely dissolved, then add 30mmol 1-vinylimidazole, and stir the resulting solution at 60°C for 24h. The reaction product was filtered, washed with a solvent, and dried in vacuum to obtain 4.27 g of a brown-yellow triazine ionic liquid monomer (compound represented by formula II).

[0027] Compound shown in formula II: 1 H NMR(300MHz,DMSO):δ=8.92(s,3H),7.92(d,3H),7.75(d,3H), 5.45(d,3H),5.3(s,3H),5.20(d,3H ) ppm. 13 C NMR (300MHz, DMSO): δ=167.0, 137.0, 123.4, 123.0, 128.4, 101.8ppm.

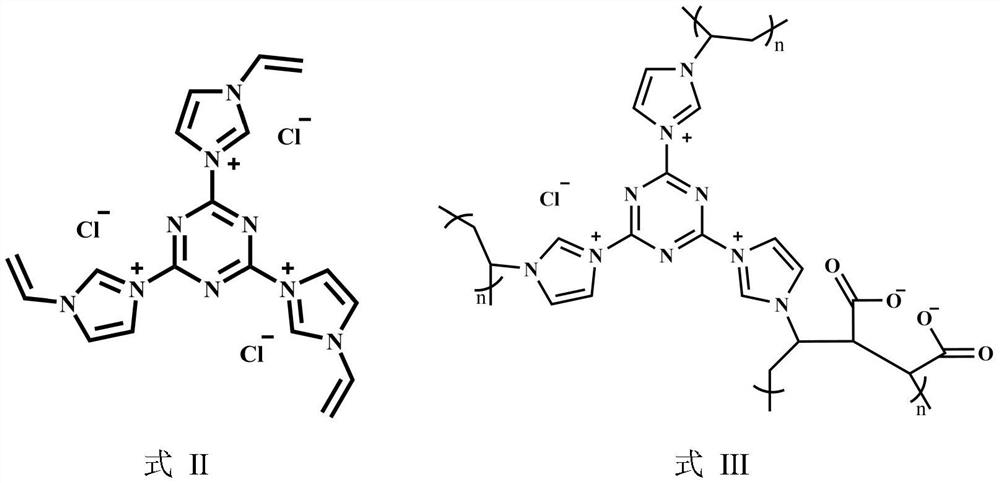

[0028] Step 2. Add 5mmol of triazine ionic liquid monomer and 5mmol of sodium maleate into a mixed solvent of 10mL of water / 20mL of ethanol, add 0.25mmol of initiator benzoyl peroxide under stirring, and place at 80°C under nitrogen protection Reaction 24h. The product was collected by filtration and dried to obt...

Embodiment 2

[0031] Preparation of Cobalt Acetate Coordinated Triazine Polyionic Liquid

[0032]

[0033] Step 1. Add 10mmol cyanuric chloride to 50mL acetonitrile and stir until completely dissolved, then add 30mmol 1-vinylimidazole, and stir the resulting solution at 80°C for 12h. The reaction product was filtered, washed with a solvent, and dried in vacuum to obtain 4.02 g of a brown-yellow triazine ionic liquid monomer (compound represented by formula II).

[0034] Step 2. 5mmol triazine ionic liquid monomer and 5mmol potassium maleate are added in the mixed solvent of 10mL water / 30mL ethanol, add initiator azobisisobutylamidine hydrochloride 0.5mmol under stirring, under nitrogen gas Under protection, react at 70°C for 24h. The product was collected by filtration and dried to obtain 2.08 g of triazine polyionic liquid (compound represented by formula III).

[0035] Step 3. Mix 1 g of triazine polyionic liquid monomer and 1.5 g of cobalt acetate into 100 mL of toluene, and stir at...

Embodiment 3

[0037] Preparation of Copper Propionate Coordinated Triazine Polyionic Liquid

[0038]

[0039] Step 1. Add 10mmol cyanuric chloride to 50mL tetrahydrofuran and stir until completely dissolved, then add 40mmol 1-vinylimidazole, and stir the resulting solution at 70°C for 12h. The reaction product was filtered, washed with a solvent, and dried in vacuum to obtain 3.85 g of a brown-yellow triazine ionic liquid monomer (compound represented by formula II).

[0040]Step 2. 5mmol triazine ionic liquid monomer and 5mmol lithium maleate are added in the mixed solvent of 10mL water / 40mL ethanol, add initiator azobisisobutyronitrile 0.75mmol under stirring, under nitrogen protection, at 60 ℃ reaction 36h. The product was collected by filtration and dried to obtain 2.18 g of triazine polyionic liquid (compound represented by formula III).

[0041] Step 3. Mix 1 g of triazine polyionic liquid monomer and 2 g of copper propionate into 100 ml of N,N-dimethylformamide, and stir at 120°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com