Ethanol refining method

A technology of ethanol and process, which is applied in the field of ethanol purification, can solve the problems of unrecoverable ethyl acetate, increased processing costs, and high content of sodium acetate, so as to reduce energy consumption, reduce equipment investment and energy consumption, and improve the utilization rate of heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

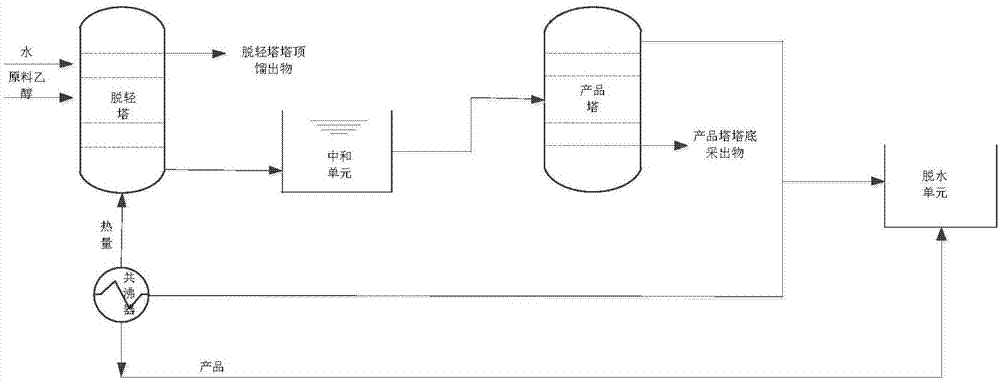

Method used

Image

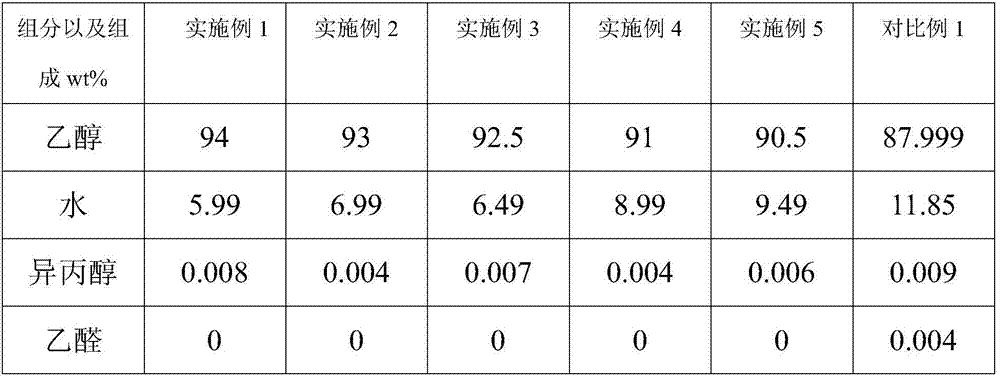

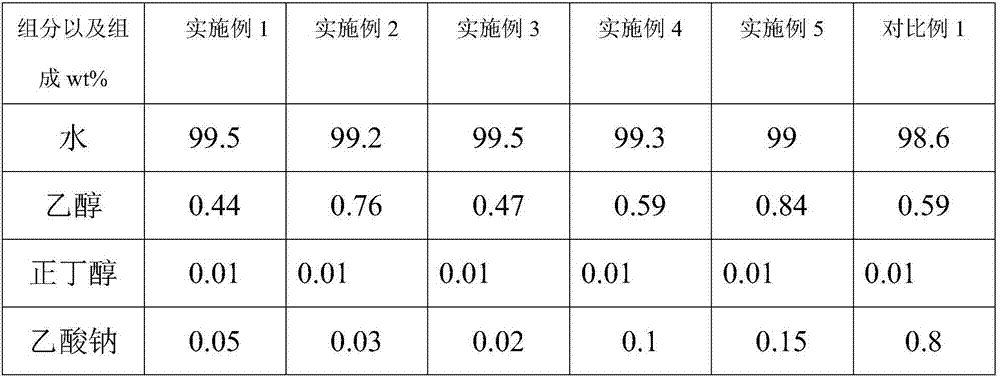

Examples

Embodiment 1

[0030] The present embodiment provides a kind of ethanol refining process, comprises the following steps:

[0031] Step 1, the ethanol raw material and water are respectively passed into the light removal tower according to the mass ratio of 0.1:1 for light removal, and the overhead distillate and the bottom residue are obtained by separation;

[0032] Wherein the overhead distillate includes hydrogen, methane, acetaldehyde, ether, acetone and ethyl acetate, and the bottom residue includes ethanol, water, acetic acid, isopropanol and n-butanol;

[0033] The top gauge pressure of the light removal tower is 10kpa, the ethanol raw material enters from the middle part of the light removal tower, and the water enters the light removal tower from the upper part where ethanol enters the light removal tower;

[0034] Step 2, the sodium hydroxide solution and the bottom residue of the light removal tower are sent to the neutralization unit reactor for neutralization, the pH value of th...

Embodiment 2

[0038] like figure 1 As shown, the present embodiment provides a kind of ethanol refining process, comprises the steps:

[0039] Step 1, the ethanol raw material and water are respectively passed into the delightening tower according to the mass ratio of 1:1 to carry out lightening, and the overhead distillate and the bottom residue are separated to obtain;

[0040] Wherein the overhead distillate includes hydrogen, methane, acetaldehyde, ether, acetone and ethyl acetate, and the bottom residue includes ethanol, water, acetic acid, isopropanol and n-butanol;

[0041] The top gauge pressure of the light removal tower is 20kpa, the ethanol raw material enters from the middle part of the light removal tower, and water enters the light removal tower from the upper part where the ethanol enters the light removal tower;

[0042] Step 2, the sodium hydroxide solution and the bottom residue of the light removal tower are sent to the reactor (neutralization unit) for neutralization, a...

Embodiment 3

[0046] The present embodiment provides a kind of ethanol refining process, comprises the following steps:

[0047] Step 1, the ethanol raw material and water are respectively passed into the delightening tower according to the mass ratio of 0.5:1 for lightening, and the overhead distillate and the bottom residue are obtained by separation;

[0048] Wherein the overhead distillate includes hydrogen, methane, acetaldehyde, ether, acetone and ethyl acetate, and the bottom residue includes ethanol, water, acetic acid, isopropanol and n-butanol;

[0049] The top gauge pressure of the light removal tower is 30kpa, the ethanol raw material enters from the middle part of the light removal tower, and the water enters the light removal tower from the upper part where ethanol enters the light removal tower;

[0050] Step 2, the sodium carbonate solution and the bottom residue of the light removal tower are sent to the reactor for neutralization, the pH value of the bottom residue of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com