Method for simultaneously removing high-boiling-point substances and low-boiling-point substances in organic silicon crude monomer

A technology of organosilicon and high boilers, applied in the field of organosilicon purification, can solve the problem of high energy consumption, reduce equipment investment, reduce investment and land occupation, and simplify the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be noted that the following detailed descriptions are exemplary and are intended to provide further explanation of the present invention. Unless otherwise indicated, all technical and scientific terms used in the present invention have the same meaning as those commonly understood by those skilled in the technical field to which the invention belongs.

[0016] A method for simultaneous removal of high and low boiling matter from silicone crude monomers, comprising the following steps:

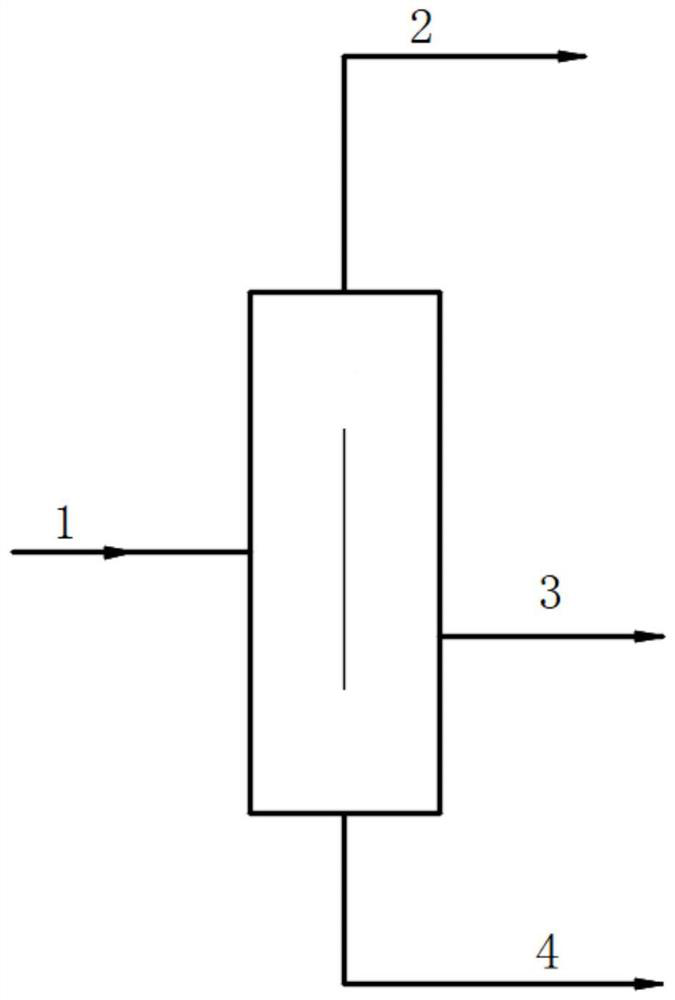

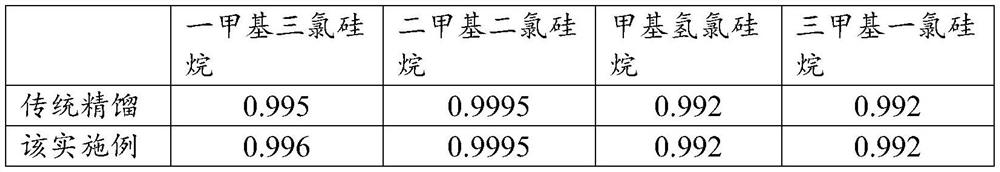

[0017] The silicone crude monomer is passed into one side of the separator of the next tower, the upper part of the next tower realizes the separation of low boiling and monomethyl trichlorosilane, the lower part of the next column realizes the separation of high boiling matter and dimethyldichlorosilane, and the other side of the separator realizes the extraction of monomethyl trichlorosilane and dimethyldichlorosilane.

[0018] In some embodiments, the interior of the next tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com