Method for determining content of organic peroxide

A technology of organic peroxide and content, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of high accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment is used to illustrate the establishment of organic peroxide standard curve

[0059] (1) Solution preparation

[0060] Preparation of standard solution: take 250mg organic peroxide (DTBP, TBPPI, TBPEH or TBPIN) standard sample and dissolve it in 250mg isododecane, then add different amounts of methanol, shake well and mix to obtain a concentration of 1% by weight, 5 wt% and 8 wt% standard solutions.

[0061] Before the HPLC detection of the standard solution, the standard solution was filtered with a 0.45 μm filter membrane.

[0062] (2) HPLC analysis

[0063] This embodiment establishes the standard curve of DTBP, TBPPI, TBPEH and TBPIN according to the following method successively

[0064] High performance liquid chromatography: Shimadzu LC-2030;

[0065] Chromatographic column: reversed C18 column, Poroshell 120;

[0066] Detector: UV-Vis spectrophotometer LAMBDA25, wavelength 254nm;

[0067] Column temperature: 30°C;

[0068] Mobile phase: for...

Embodiment 2

[0077] This embodiment is used to illustrate the mensuration of organic peroxide test sample content

[0078] The preparation of the sample to be tested: take organic peroxide (DTBP, TBPPI, TBPEH or TBPIN) standard sample, use isododecane to be respectively formulated with the TBPPI of 25.12% by weight, the TBPEH of 30.15% by weight, the TBPIN of 30.18% by weight and 49.92% by weight DTBP.

[0079] After fully mixing 9 parts by weight of methanol and 1 part by weight of the sample to be tested, the sample solution to be tested was obtained, and before the HPLC detection of the sample solution to be tested, the sample solutions to be tested were respectively filtered using 0.45 μm filter membranes.

[0080] The concentration of the above-mentioned sample solution to be tested was determined according to the HPLC analysis method described in Example 1, with 8 parallels for each solution.

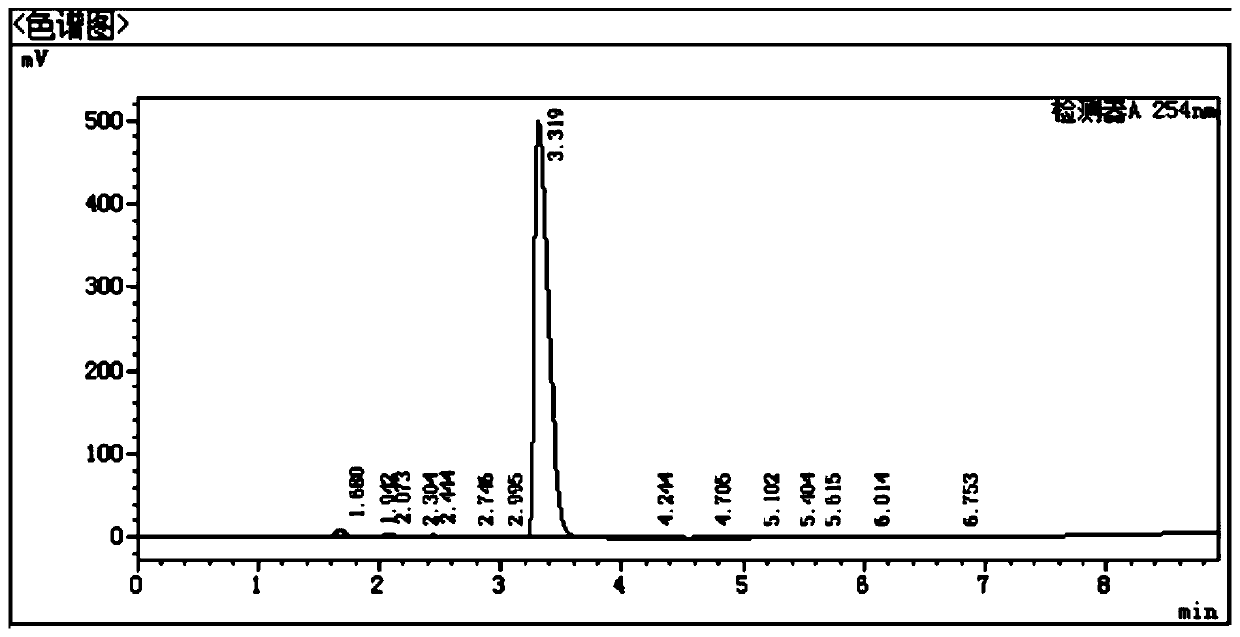

[0081] Taking TBPEH as an example, the 30.15% by weight TBPEH sample to be tested was ana...

Embodiment 3

[0086] This embodiment is used to illustrate the mensuration of organic peroxide test sample content

[0087] Preparation of sample to be tested: take organic peroxide (TBPPI, TBPEH and TBPIN) standard sample, use isododecane to prepare TBPPI (10% by weight), TBPEH (15% by weight) and TBPIN (20% by weight) Mix the samples.

[0088] After fully mixing 9 parts by weight of methanol and 1 part by weight of the sample to be tested, the sample solution to be tested was obtained, and before the HPLC detection of the sample solution to be tested, the sample solutions to be tested were respectively filtered using 0.45 μm filter membranes.

[0089] The concentration of the above-mentioned sample solution to be tested was determined according to the HPLC analysis method described in Example 1, and a total of 3 parallels were performed.

[0090] According to HPLC analysis, the content of each component in the sample to be tested is: TBPPI 10.76±0.42 wt%, TBPEH 15.56±0.57 wt%, and TBPIN ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com