Method for collaboratively preparing nickel sulfate by desulfurization and denitration by reducing calcined ore pulp from ammonia-strengthened lateritic ore and system

A technology of laterite ore and nickel sulfate, which is applied in the direction of improving process efficiency, can solve the problems of large ammonia volatilization loss, complex process and high energy consumption, and achieves reduced energy consumption and labor intensity, high resource utilization rate and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

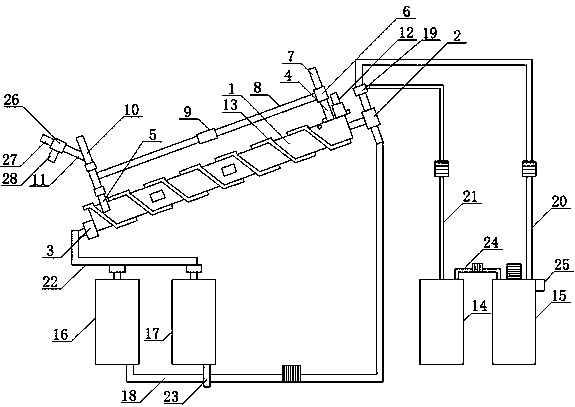

Image

Examples

Embodiment 1

[0045] S1. First reduce and roast the laterite ore, and crush and grind the reduced calcine of the laterite ore until the particle size is less than 1mm, add ammonia water, and fully mix to obtain the ore pulp;

[0046] S2, will contain SO 2 , NO X flue gas and O 2 Drum directly into the slurry in step S1, fully contact, and maintain an oxidizing atmosphere. The laterite ore is reduced to calcine at 50°C, so that nickel and cobalt are fully complexed and leached, and the pH value of the leachate is controlled by supplementing ammonia water. gas discharge;

[0047] S3, performing solid-liquid separation on the ore pulp treated in step S2 to obtain filtrate and filter residue, and discharge the filter residue;

[0048] S4. In the separated filtrate, first add a precipitating agent to precipitate cobalt, separate the solid and liquid to obtain a liquid, and after the ammonia is recovered by heat, a nickel sulfate solution is obtained;

Embodiment 2

[0050] S1. First reduce and roast the laterite ore, and crush and grind the reduced calcine of the laterite ore until the particle size is less than 1mm, add ammonia water, and fully mix to obtain the ore pulp;

[0051] S2, will contain SO 2 , NO X flue gas and O 2 Drum directly into the slurry in step S1, fully contact, and maintain an oxidizing atmosphere. The laterite ore is reduced to calcine at 70°C, so that nickel and cobalt are fully complexed and leached, and the pH value of the leachate is controlled by supplementing ammonia water. gas discharge;

[0052] S3, performing solid-liquid separation on the ore pulp treated in step S2 to obtain filtrate and filter residue, and discharge the filter residue;

[0053] S4. In the separated filtrate, a precipitant is first added to precipitate cobalt, and the solid-liquid is separated to obtain a liquid. After the ammonia is recovered by heat, a nickel sulfate solution is obtained.

Embodiment 3

[0055] S1. First reduce and roast the laterite ore, and crush and grind the reduced calcine of the laterite ore until the particle size is less than 1mm, add ammonia water, and fully mix to obtain the ore pulp;

[0056] S2, will contain SO 2 , NO X flue gas and O 2 Drum directly into the slurry in step S1, fully contact, and maintain an oxidizing atmosphere. The laterite ore is reduced to calcine at 60°C, so that nickel and cobalt are fully complexed and leached, and the pH value of the leachate is controlled by supplementing ammonia water. gas discharge;

[0057] S3, performing solid-liquid separation on the ore pulp treated in step S2 to obtain filtrate and filter residue, and discharge the filter residue;

[0058] S4. In the separated filtrate, a precipitant is first added to precipitate cobalt, and the solid-liquid is separated to obtain a liquid. After the ammonia is recovered by heat, a nickel sulfate solution is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com