Ultrahigh-viscosity acrylate emulsion pressure-sensitive adhesive and preparation method thereof

An acrylate, ultra-high viscosity technology, used in the field of pressure-sensitive adhesives, can solve the problems of poor adhesion of non-polar materials, poor low-temperature adhesion, and small initial adhesion adjustment space, and achieve the effect of a wide range of performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

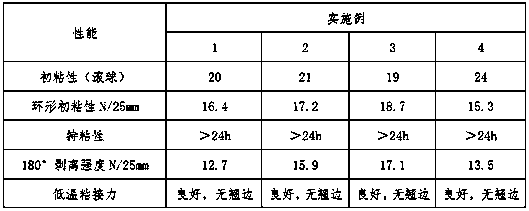

Examples

Embodiment 1

[0039] Weigh each component according to the weight ratio, add 0.3g of allyloxy nonylphenol polyoxyethylene ether sulfate to 15g of deionized water, and stir at room temperature to obtain an aqueous emulsifier solution; dissolve 0.6g of hexadecane in 15g of liquid Add the rosin resin to the emulsifier aqueous solution, stir and mix for 30 minutes, and the stirring speed is 500r / min to obtain a pre-emulsion, and then disperse the pre-emulsion in a high-speed homogenizer with a rotation speed of 15000r / min for 30 minutes to obtain a tackifying resin microemulsion;

[0040] Weigh 1.8g of allyloxy nonylphenol polyoxyethylene ether sulfate, 0.6g of allyloxy fatty alcohol polyoxyethylene ether and add it to 140g of water, stir at room temperature to obtain an emulsifier aqueous solution, and then slowly add 192g butyl acrylate, 63g isooctyl acrylate, 30g methyl methacrylate, 9g β-acryloyloxypropionic acid, 6g ethylene urea ethoxy methacrylate, 0.75g ammonium persulfate, stir for 30mi...

Embodiment 2

[0043] Weigh each component according to the weight ratio, add 0.2g allyloxy fatty alcohol oxyethylene ether sulfate, 0.1g sodium methacrylamide isopropyl sulfonate to 15g water and stir at room temperature to obtain an emulsifier aqueous solution; Dissolve 0.9g of cetyl alcohol in 27g of liquid rosin resin and add it to the emulsifier aqueous solution, stir and mix for 30min at a stirring speed of 500r / min to obtain a pre-emulsion, and then disperse the pre-emulsion in a high-speed homogenizer with a speed of 15000r / min 30min, obtain tackifying resin microemulsion;

[0044] Weigh 1.8g of alkyl allyl sulfosuccinic acid sodium salt and 0.6g of allyloxy fatty alcohol polyoxyethylene ether into 140g of water, stir at room temperature to obtain emulsifier aqueous solution, then slowly add 198g of acrylic acid to the emulsifier aqueous solution Butyl ester, 66g isooctyl acrylate, 24g methyl methacrylate, 6g acrylic acid, 6g acetoacetoxyethyl methacrylate, 0.75g ammonium persulfate,...

Embodiment 3

[0047] Weigh each component according to the weight ratio, add 0.5g of allyloxy fatty alcohol oxyethylene ether sulfate to 15g of water and stir at room temperature to obtain an emulsifier aqueous solution; dissolve 0.6g of hexadecane in 12g of liquid rosin resin and add it to In the emulsifier aqueous solution, stir and mix for 30min at a stirring speed of 500r / min to obtain a pre-emulsion, and then disperse the pre-emulsion in a high-speed homogenizer with a rotation speed of 15000r / min for 30min to obtain a tackifying resin microemulsion;

[0048] Weigh 1.8g of alkyl allyl sulfosuccinic acid sodium salt and 0.6g of allyloxy fatty alcohol oxyethylene ether sulfate into 140g of water, stir at room temperature to obtain an emulsifier aqueous solution, and then slowly add 189g of emulsifier to the emulsifier aqueous solution Butyl acrylate, 63g isooctyl acrylate, 33g methyl methacrylate, 6g methacrylic acid, 9g N-hydroxyethyl acrylamide, 0.75g ammonium persulfate, stirred for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com