Production method of modified casein label adhesive

A production method and casein technology are applied in the preparation of animal glue or gelatin, adhesives, adhesive types, etc., and can solve the problems of poor water resistance of label glue, high cost of casein glue A, and inability to meet demand, etc. Water resistance, excellent ice water resistance time, and the effect of improving ice water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

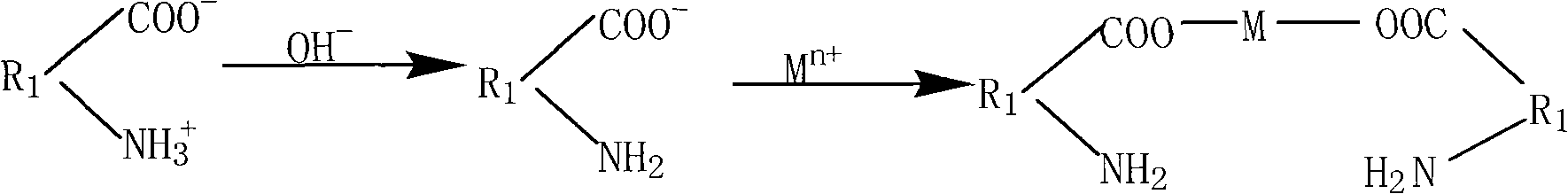

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 A kind of production method of modified casein label glue, comprises the following steps:

[0043] (1) Add polyvinyl alcohol into a four-necked flask filled with distilled water, place it in a heat-regulating electric heating mantle, stir and raise the temperature to 90°C to completely dissolve the polyvinyl alcohol, keep it warm for 50-60 minutes, and then cool down to 70°C °C to obtain a polyvinyl alcohol solution. Wherein the mass ratio of polyvinyl alcohol to water is 1:3.8.

[0044] (2) Put borax and casein in a beaker containing distilled water, heat and stir at 60°C for 30-35 minutes with a heat-adjusting electric heating mantle to fully dissolve them in water to obtain a casein solution; keep warm for later use . Wherein the mass ratio of borax to water is 1:29, and the mass ratio of casein to water is 1:4.

[0045] (3) putting cornstarch and water in distilled water at a temperature of 80°C in a mass ratio of 1: 1.2, and stirring constantly for ...

Embodiment 2

[0051] Embodiment 2 A kind of production method of modified casein label glue, comprises the following steps:

[0052] (1) Add polyvinyl alcohol into a four-neck flask filled with distilled water, place it in a heat-regulating electric heating mantle, stir and raise the temperature to 93°C to completely dissolve the polyvinyl alcohol, keep it warm for 50-60min, then cool down to 73°C °C to obtain a polyvinyl alcohol solution. Wherein the mass ratio of polyvinyl alcohol to water is 1:4.2.

[0053] (2) Put borax and casein in beakers containing distilled water, respectively, and stir at 63° C. for 30 to 35 minutes with a heat-regulating electric heating mantle to fully dissolve them in water to obtain a casein solution; keep warm for later use. The mass ratio of borax to water is 1:30, and the mass ratio of casein to water is 1:4.5.

[0054] (3) putting cornstarch and water in distilled water at a temperature of 83°C in a mass ratio of 1: 1.3, and stirring constantly for gelat...

Embodiment 3

[0060] Embodiment 3 A kind of production method of modified casein label glue, comprises the following steps:

[0061] (1) Add polyvinyl alcohol into a four-neck flask filled with distilled water, place it in a heat-adjusting electric heating mantle, stir and raise the temperature to 95°C to completely dissolve the polyvinyl alcohol, keep it warm for 50-60 minutes, and then cool down to 75°C °C to obtain a polyvinyl alcohol solution. Wherein the mass ratio of polyvinyl alcohol to water is 1:4.5.

[0062] (2) Put the borax and casein in a beaker containing distilled water respectively, and stir at 65° C. for 30 to 35 minutes with a heat-regulating electric heating mantle to fully dissolve them in water to obtain a casein solution; keep warm for later use. The mass ratio of borax to water is 1:31, and the mass ratio of casein to water is 1:5.

[0063] (3) putting cornstarch and water in distilled water at a temperature of 85°C in a mass ratio of 1:1.5, and stirring constantly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com