Microsphere aluminum oxide catalyst, and preparation method and application thereof

A kind of alumina and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, refined hydrocarbon oil, etc., can solve the problems of difficult to obtain high solid content water slurry, changes in the characteristics of alumina raw materials, and low efficiency of spray drying process To achieve the effect of wide particle size control space, excellent particle size distribution and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

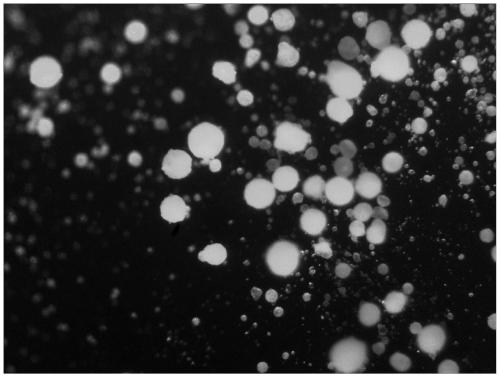

[0043] Embodiment 1 prepares microsphere alumina catalyst

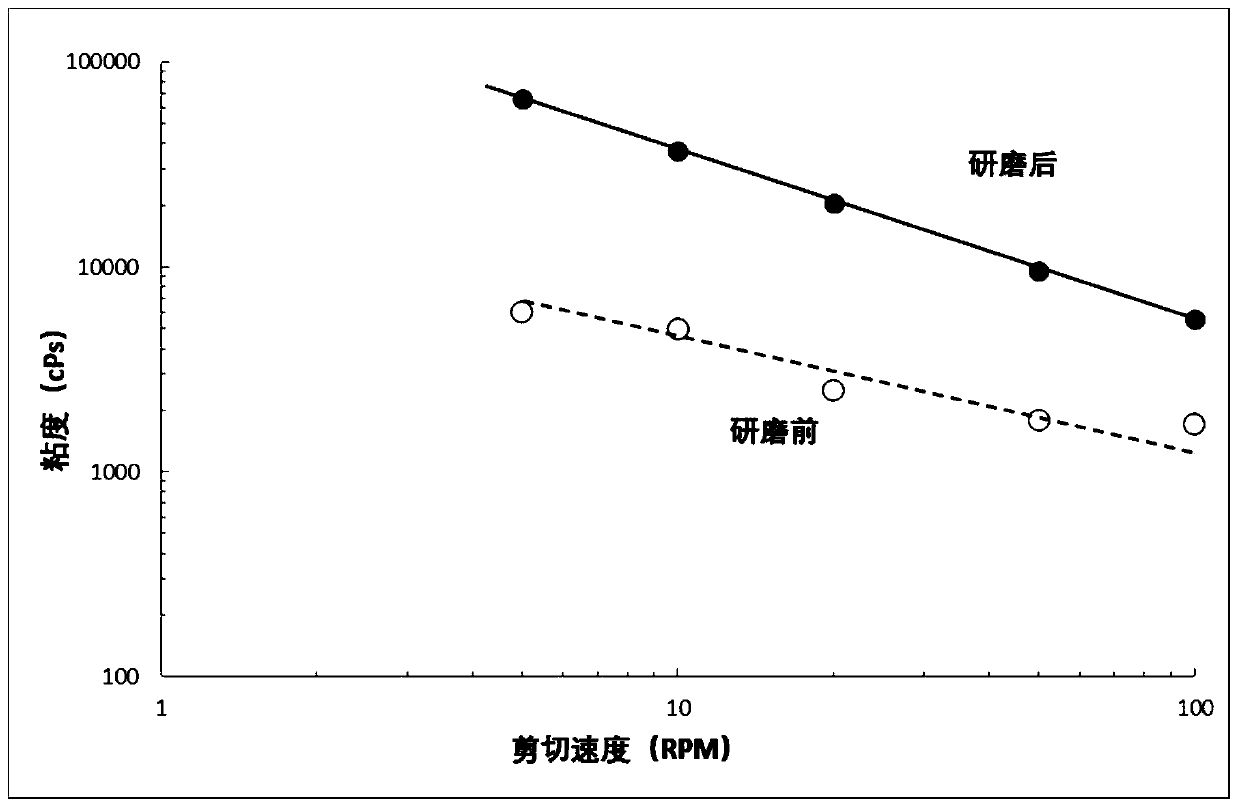

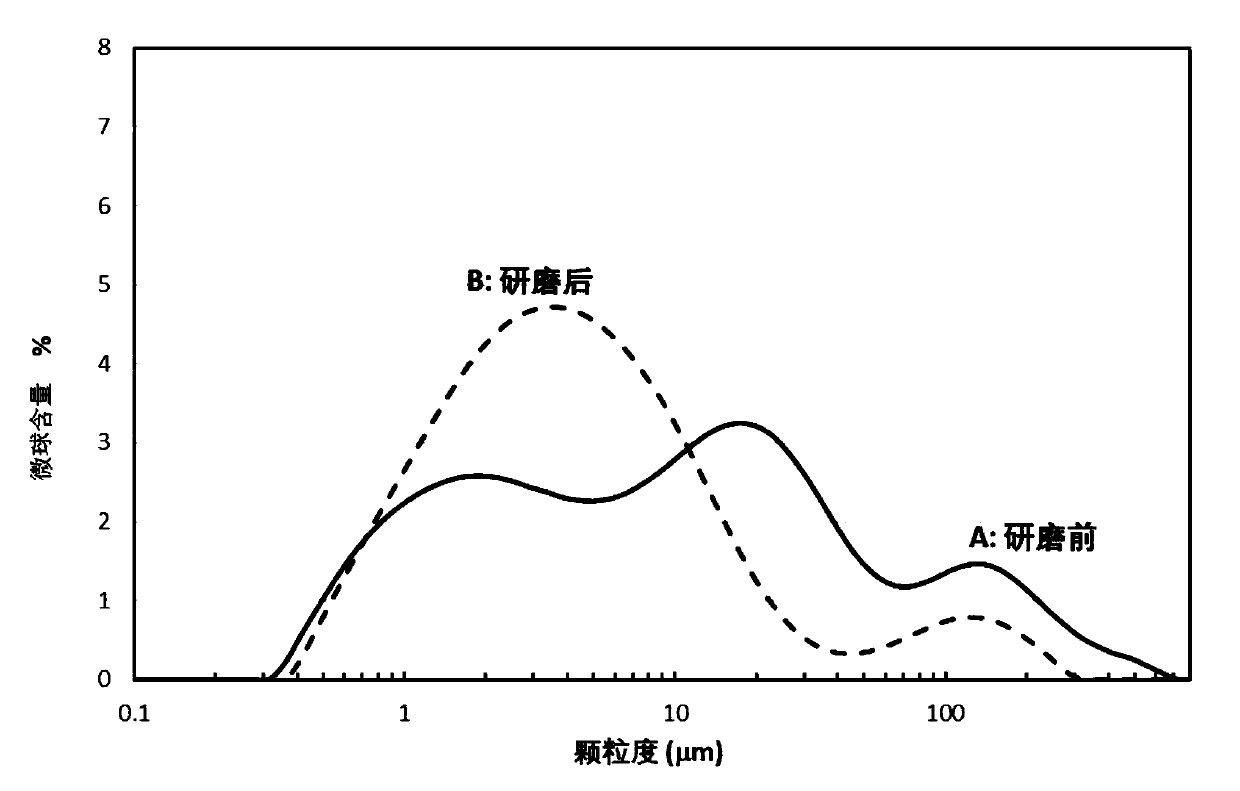

[0044] (1) Water slurry preparation: take by weighing 2913 grams of deionized water and add in the stirring tank, add 1066 grams of alumina powder to the deionized water under the stirring situation, the ignition loss of this alumina powder is 25.35%, and its sodium oxide (Na 2 The content of O) is 0.021wt%, and the purity of alumina is 99.95%. ; The stirring speed was controlled at 380 RPM, stirred for 3 hours, and 3979 grams of water slurry was obtained. The solid content of the water slurry was 20%, the pH was 8.26, and the conductivity was 116.5 mm / cm. Other properties are shown in Table 1 and Table 2.

[0045] (2) primary refinement of particles: the alumina water slurry prepared in step (1) is sent to the Eiger Mini-250 grinder of the U.S. Eiger Machinery Equipment Company by a delivery pump for grinding. The speed of the grinder is 2400RPM, and the processing speed The temperature of the grinding chamber is c...

Embodiment 2

[0058] Embodiment 2 prepares microsphere alumina catalyst

[0059] (1) Water slurry preparation: Weigh 14.85 kg of deionized water and put it into a 30-liter 316L stainless steel mixing tank. The inner wall of the tank is equipped with a baffle, put the stirrer in the center of the liquid in the mixing tank, and adjust the stirring speed to 120 RPM; When starting to add alumina powder, adjust the speed of the stirring paddle to 520RPM, stir and gradually add 10.78kg of alumina powder, and stir for 8 hours to obtain 25.63kg of water slurry. The ignition loss of the alumina powder is 26.27%. The sodium content is 0.033wt%, the solid content of the prepared water slurry is 31.0%, the pH is 8.12, and the electrical conductivity is 120.3mm / cm.

[0060] (2) Particle refinement: the alumina slurry prepared in step (1) was sent to the LM-0.5 grinder of Germany Netzsch Mechanical Equipment Co., Ltd. for slurry particle refinement with a speed of 2400 RPM by means of a transfer pump. T...

Embodiment 3

[0064] Embodiment 3 prepares microsphere alumina catalyst

[0065] (1) Water slurry preparation: Weigh 14.85 kg of deionized water and put it into a 30-liter 316L stainless steel mixing tank. The inner wall of the tank is equipped with a baffle, put the stirrer in the center of the liquid in the mixing tank, and adjust the stirring speed to 120 RPM; When starting to add alumina powder, adjust the speed of the stirring paddle to 520RPM, stir and gradually add 10.78kg of alumina powder, and stir for 8 hours to obtain 25.63kg of water slurry. The ignition loss of the alumina powder is 26.27%. The sodium content is 0.033wt%, the solid content of the prepared water slurry is 31.0%, the pH is 8.12, and the electrical conductivity is 120.3mm / cm.

[0066] (2) Particle refinement: the alumina slurry prepared in step (1) was sent to the LM-0.5 grinder of Germany Netzsch Mechanical Equipment Co., Ltd. for slurry particle refinement with a speed of 2400 RPM by means of a delivery pump. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com