Method for recycling nickel-cobalt-manganese waste ternary lithium battery positive electrode material

A ternary lithium battery and positive electrode material technology, applied in battery recycling, recycling technology, battery electrodes, etc., can solve the problems of low electrochemical performance of recycled products, toxic organic reagents, low recovery efficiency, etc., and achieve high stripping efficiency, Less reagents and improved recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

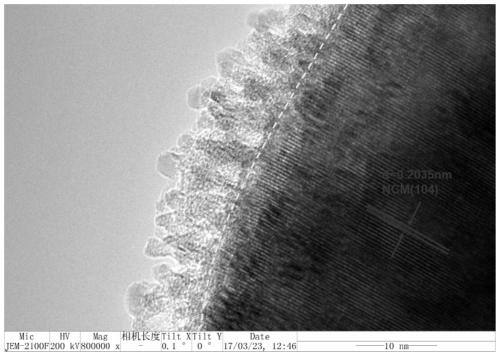

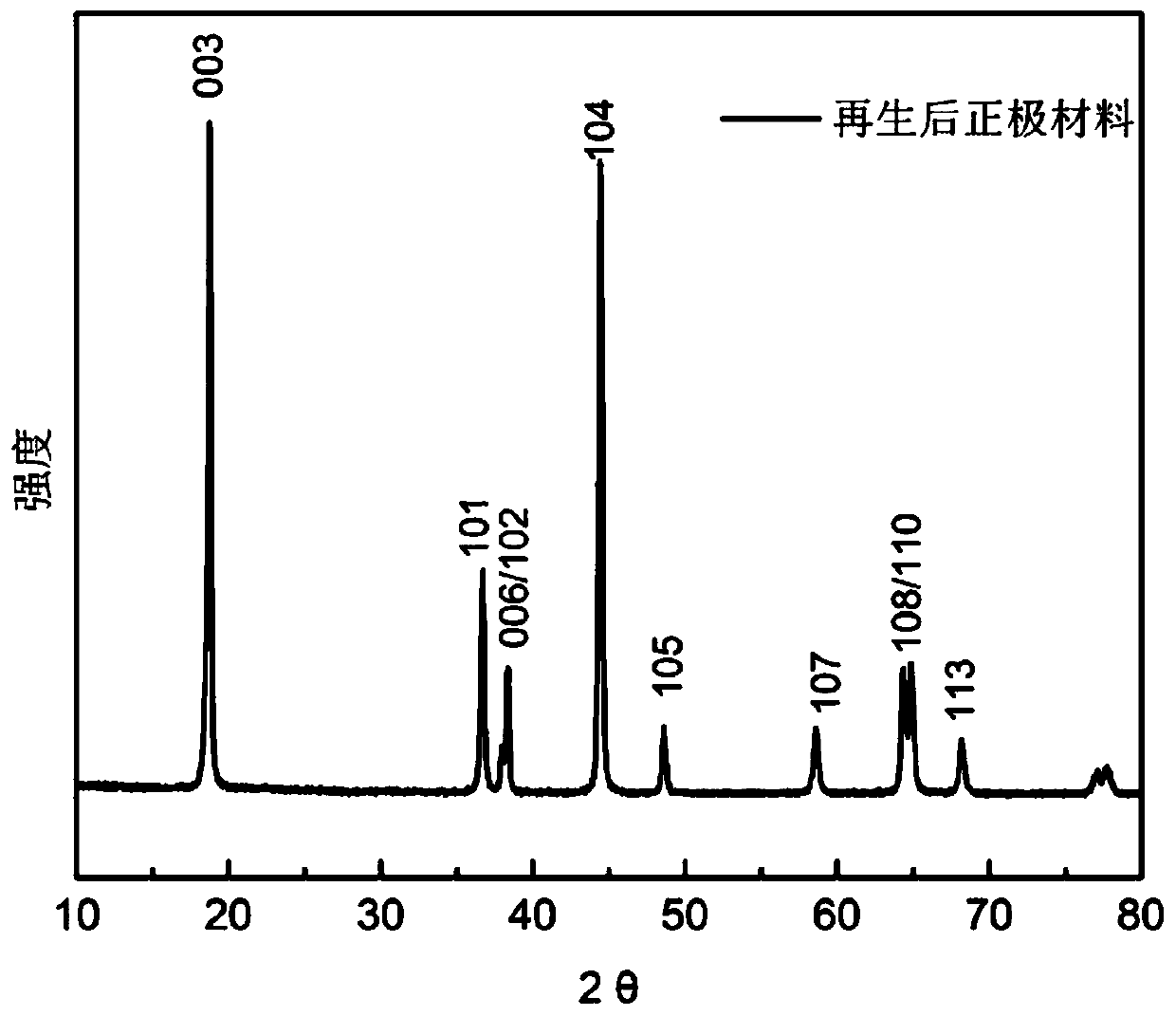

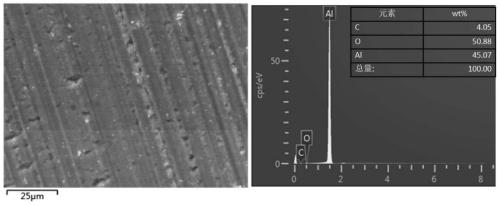

[0036] 1) After fully discharging the recovered waste lithium-ion battery (the active material in the positive electrode sheet is 84.9% nickel-cobalt manganate, and the mass fraction of aluminum is 11.7%), the open-circuit voltage after testing is 0.7V, and then dismantling , take out the positive plate;

[0037] 2) Clean the positive electrode sheet with dimethyl carbonate DMC, remove the residual electrolyte on the positive electrode sheet, and dry it in a vacuum drying oven at 60° C. for 2 hours to obtain a dry positive electrode sheet;

[0038]3) adopt ICP-OES method to measure the content of element Li, Co, Ni and Mn on the positive active material of dry positive electrode sheet, obtain the molar ratio of lithium and total transition metal to be 0.85:1, take 30 parts of dry positive electrode sheet, and its 1 wt % of aluminum nitrate contained in the positive active material above, namely 0.255 parts of aluminum nitrate, was added to 100 parts of deionized water, stirred...

Embodiment 2

[0042] Others are the same as in Example 1, except that the aluminum nitrate used is 3% by weight of the positive electrode active material.

Embodiment 3

[0044] Others are the same as in Example 1, except that the aluminum nitrate used is 5% by weight of the positive active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com