MXene/metal phosphide composite material, and anode material and preparation and application thereof

A metal phosphide, composite material technology, applied in the direction of negative electrode, active material electrode, battery electrode, etc., can solve the problems of reducing battery capacity and life, electrode material volume change, electrode pulverization, etc., to improve energy density, good Stability and collapse prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

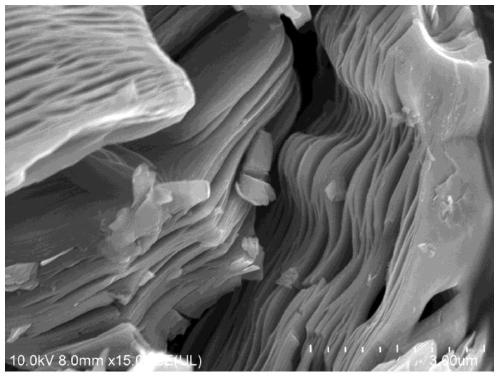

Image

Examples

Embodiment 1

[0046] (1) Weigh 1g ferric nitrate powder and 10g Ti respectively 3 C 2 Put the powder into a polytetrafluoroethylene reactor, add 20ml of deionized water to dissolve, mix and stir for 10 hours; then put it in an oven at 80°C for hydrothermal reaction, the reaction time is 8 hours; after the reaction, perform suction filtration to obtain a solid and dry it. get Ti 3 C 2 / ferric nitrate mixture;

[0047] (2) Under a nitrogen atmosphere, take 1g of the Ti prepared in step (1) 3 C 2 / ferric nitrate mixture and 4g sodium phosphite were put into a tube furnace, and the temperature was raised to 500°C at a heating rate of 2°C / min and kept for 3h to obtain Ti 3 C 2 / Iron phosphide composite material;

[0048] (3) get the Ti that 80g step (2) makes 3 C 2 / iron phosphide composite material, 10g SP, 10g PAA and water are made into a slurry, coated on copper foil, to obtain MXene / metal phosphide-based composite battery negative electrode material (Ti 3 C 2 / Fe 3 P).

[0049...

Embodiment 2

[0051] (1) Weigh 1g cobalt sulfate powder and 0.3g Ta 4 C 3 Put the powder into a polytetrafluoroethylene reactor, add 30ml of deionized water to dissolve, mix and stir for 20 hours; then put it in an oven at 120°C for hydrothermal reaction, the reaction time is 16 hours; after the reaction, perform suction filtration and dry to obtain Ta 4 C 3 / cobalt sulfate mixture.

[0052] (2) Under nitrogen atmosphere, take 1g of step (1) to prepare Ta 4 C 3 / Cobalt sulfate mixture and 3g of sodium hypophosphite are put into a tube furnace, and the temperature is raised to 700°C at a heating rate of 10°C / min and kept for 2h to obtain Ta 4 C 3 / cobalt phosphide composite material;

[0053] (3) get the Ta that 85g step (2) makes 4 C 3 / cobalt phosphide composite material, 5g vinylene, 10g CMC are made into slurry, are coated on the copper foil, obtain MXene / metal phosphide based composite battery negative electrode material (Ta 4 C 3 / CoP).

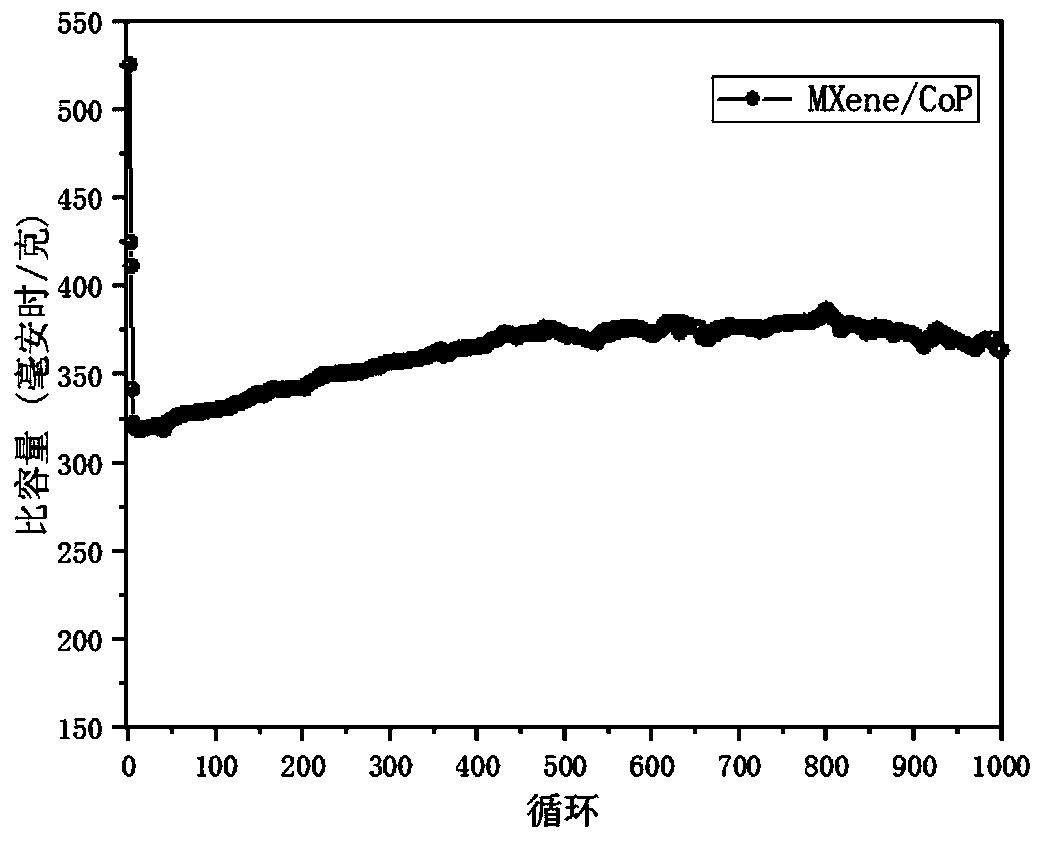

[0054] The MXene / metal phosphide-...

Embodiment 3

[0057] (1) Weigh 1g tin chloride powder and 1g V 2 Add C powder into a polytetrafluoroethylene reactor, add 50ml of deionized water to dissolve, mix and stir for 48 hours; then put it in an oven at 90°C for hydrothermal reaction, the reaction time is 20 hours; after the reaction, perform suction filtration and dry to obtain V 2 C / tin chloride mixture;

[0058] (2) Under nitrogen atmosphere, take 1g of V prepared in step (1) 2 C / tin chloride mixture and 1g of sodium hypophosphite were placed in a tube furnace, and the temperature was raised to 400°C at a rate of 20°C / min and kept for 4 hours to obtain V 2 C / tin phosphide mixture;

[0059] (3) Get 70g of V prepared in step (2) 2 C / tin phosphide composite material, 15g conductive carbon black, 15g CMC are made into slurry, are coated on carbon paper, obtain MXene / metal phosphide based composite battery negative electrode material (V 2 C / Sn 3 P 2 ).

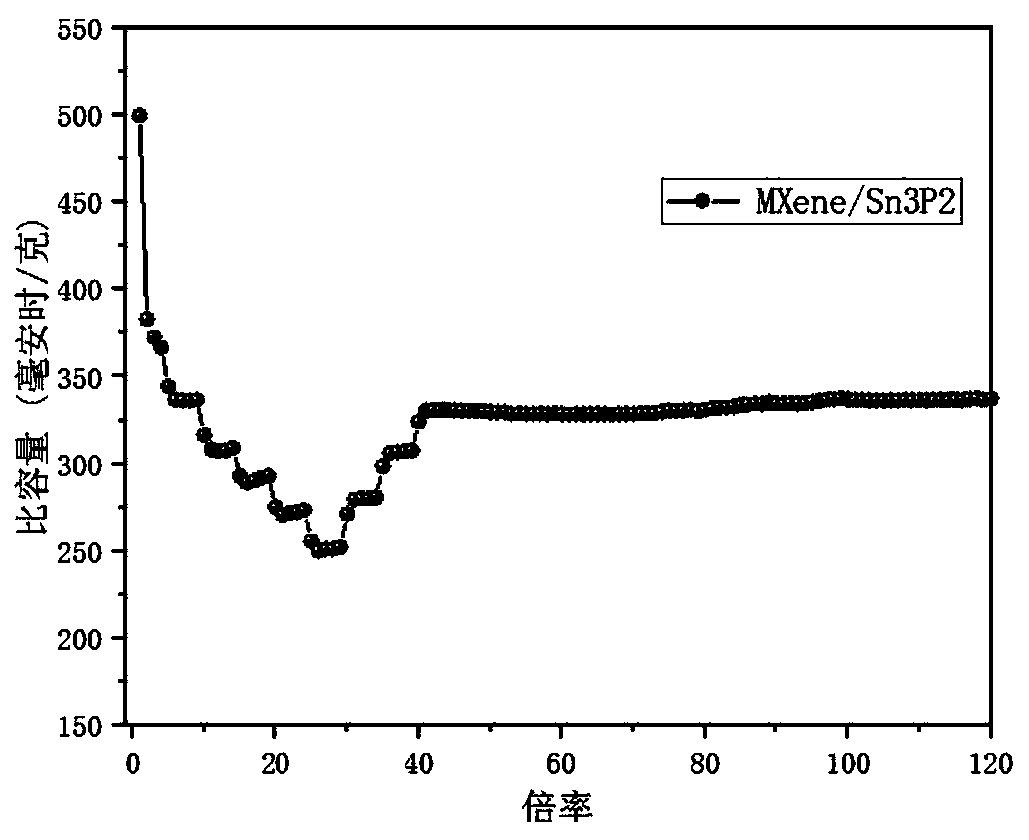

[0060] The MXene / metal phosphide-based composite battery negative elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com