Method for extracting manganese and comprehensively recovering nickel, cobalt and copper by beneficiation and smelting of cobalt-manganese polymetallic oxide ore

A combination of multi-metal oxide ore, dressing and smelting technology, applied in the direction of improving process efficiency, can solve the problems of complex purification process, hard cold alloy and slag, high cost, etc., and achieve less post-processing, simple process and high recovery rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

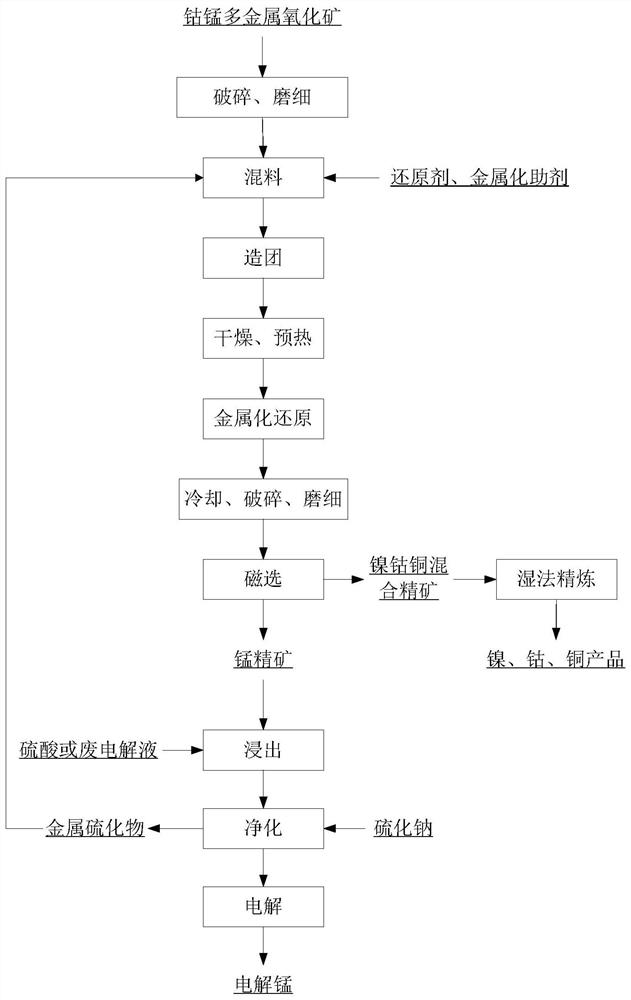

Image

Examples

Embodiment approach

[0038] (1) The cobalt-manganese polymetallic oxide ore is one or more mixtures of seabed polymetallic nodules, seabed cobalt-rich crusts, terrestrial associated polymetallic manganese oxide ore, and cobalt earth ore.

[0039] (2) In step 1, the particle size of the powder ore is less than 0.074mm, accounting for more than 80%.

[0040] (3) In step 2, the reducing agent is a mixture of one or more of carbonaceous reducing agents such as coal, coke, biomass, etc., preferably coal; the addition of the reducing agent is cobalt-manganese polymetallic oxidation 2% to 15% of the total mass of the ore.

[0041] (4) In step 2, the metallization assistant is one or a mixture of two in fluoride and silicon dioxide; the addition amount of each metallization assistant does not exceed the total mass of the cobalt-manganese polymetallic oxide ore 10%.

[0042] (5) In step 2, the powder ore obtained in step 1 is mixed with the metal sulfide obtained in step 6, then mixed with a reducing agent...

Embodiment 1

[0053] A method for combined extraction of manganese and comprehensive recovery of nickel, cobalt and copper from cobalt-manganese polymetallic oxide ore beneficiation The treatment of polymetallic oxide ore may include the following steps:

[0054] In step 1A, the cobalt-manganese polymetallic oxide ore is crushed and ground to a particle size of less than 0.074mm, accounting for more than 80%, so as to obtain powder ore.

[0055] Step 2A: Mix the powder ore prepared in Step 1A with anthracite that accounts for 5% of the total mass of the cobalt-manganese polymetallic oxide ore, add a certain amount of water, and press into pellets with a diameter of 20 mm.

[0056] In step 3A, the pellets obtained in step 2A are subjected to drying and preheating treatment, the temperature of drying and preheating is 250°C, and the time of drying and preheating is 4h, and then transferred to a closed heating furnace for metallization reduction roasting at 1150°C 2.5h, the material after red...

Embodiment 2

[0062] A method for combined extraction of manganese and comprehensive recovery of nickel, cobalt and copper from cobalt-manganese polymetallic oxide ore beneficiation The treatment of polymetallic oxide ore may include the following steps:

[0063] In step 1B, the cobalt-manganese polymetallic oxide ore is crushed and ground to a particle size of less than 0.074mm, accounting for more than 90%, so as to obtain powder ore.

[0064] In step 2B, the powder ore obtained in step 1B is uniformly mixed with coal which accounts for 10% of the total mass of the cobalt-manganese polymetallic oxide ore, and a certain amount of water is added to form pellets with a diameter of 20 mm.

[0065] In step 3B, the pellets obtained in step 2B are subjected to drying and preheating treatment, the temperature of drying and preheating is 180°C, and the time of drying and preheating is 5h, and then transferred to a closed heating furnace for metallization reduction roasting at 1200°C 3h, the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com