Modified carbon nanotube reinforced shape memory epoxy resin composite material and preparation method thereof

An epoxy resin and composite material technology, applied in the field of composite materials, can solve the problems of insufficient stability of the combination of nano materials and epoxy resin matrix, and achieve the effects of excellent mechanical properties, improved mechanical properties, and enhanced interface bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Preparation of modified carbon nanotubes

[0047] (1) Grafting carboxyl groups on the surface of carbon nanotubes

[0048] 3 g of carbon nanotubes were added to a single-necked flask containing a mixed acid solution of 20 mL of concentrated nitric acid and 60 mL of concentrated sulfuric acid, and then the single-necked flask was placed in an ultrasonic separator and kept at 80 ° C for 6 h for acidification. After the reaction is completed, the mixed solution is centrifuged several times until the solution is neutral, and the obtained solution is dried to obtain a carbon nanotube solid powder with carboxyl groups on the surface.

[0049] (2) Epoxy groups grafted on the surface of carbon nanotubes

[0050] Add 10g of epoxy resin E-51 into a three-necked flask containing 50mL of N-N dimethylacetamide and stir until the solution is uniform, then add 3g of carboxy-modified carbon nanotube powder and 0.05g of triphenyl Base phosphine, keep the epoxidation reac...

Embodiment 2

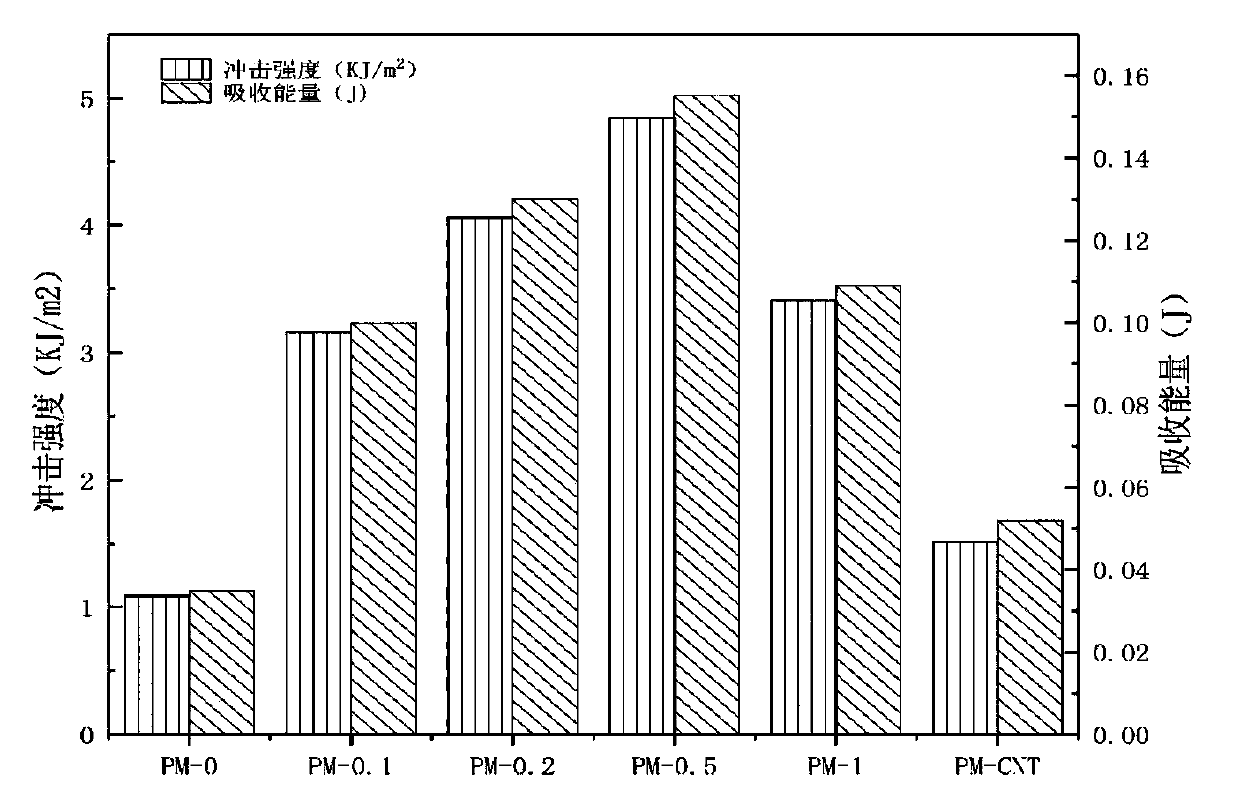

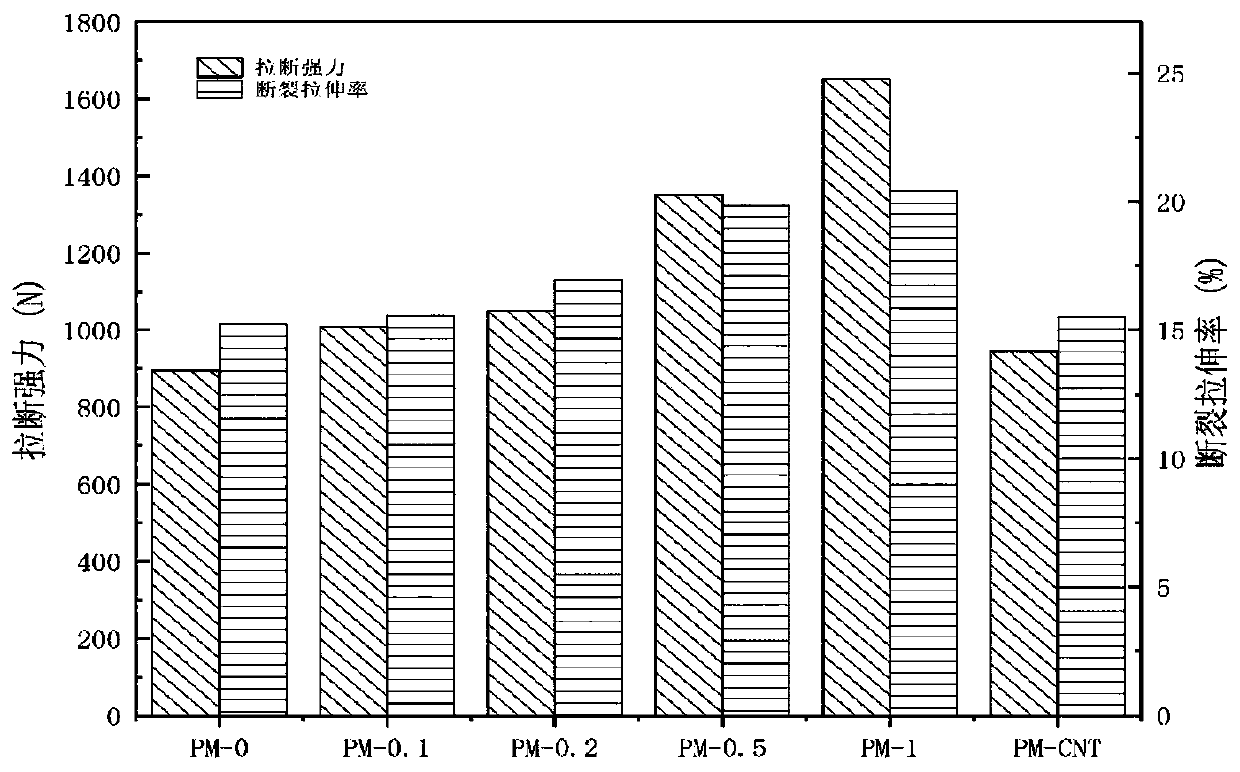

[0053] After mixing 3.65g of epoxy resin E-51 quality, 1.72g of tetrakis(3-mercaptopropionate) pentaerythritol ester, 0.0054g of epoxy-modified carbon nanotubes, and 0.075g of catalyst 2-methylimidazole . Place the above-mentioned polymerized monomers and catalysts under -0.08MPa vacuum condition, and stir for 30min. Pour the well-stirred mixture into a polytetrafluoroethylene mold, and place it under vacuum conditions, react at 80°C for 3h, at 120°C for 2h, and at 150°C for 1h, after 24 hours of subsequent natural cooling treatment, the modified carbon was prepared. Nanotube-reinforced shape-memory epoxy resin composite PM-0.1.

Embodiment 3

[0055] After mixing 3.65g of epoxy resin E-51 quality, 1.72g of tetrakis (3-mercaptopropionic acid) pentaerythritol ester, 0.0108g of epoxy-modified carbon nanotubes, and 0.075g of catalyst 2-methylimidazole . Place the above-mentioned polymerized monomers and catalysts under -0.08MPa vacuum condition, and stir for 30min. Pour the well-stirred mixture into a polytetrafluoroethylene mold, and place it under vacuum conditions, react at 80°C for 3h, at 120°C for 2h, and at 150°C for 1h, after 24 hours of subsequent natural cooling treatment, the modified carbon was prepared. Nanotube-reinforced shape-memory epoxy resin composite PM-0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com