Production of articles made of composite materials by 3d-printing method

A technology for composite materials and products, applied in the field of additives, to achieve the effects of reducing porosity, uniform internal structure, and improving specific strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

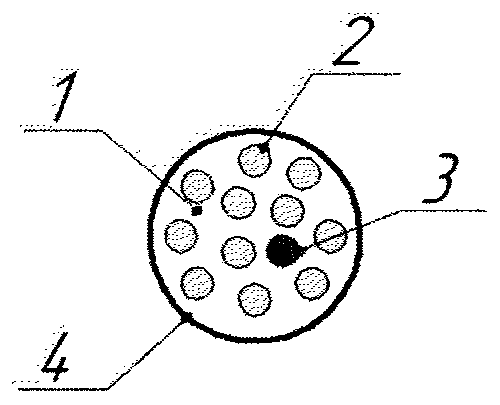

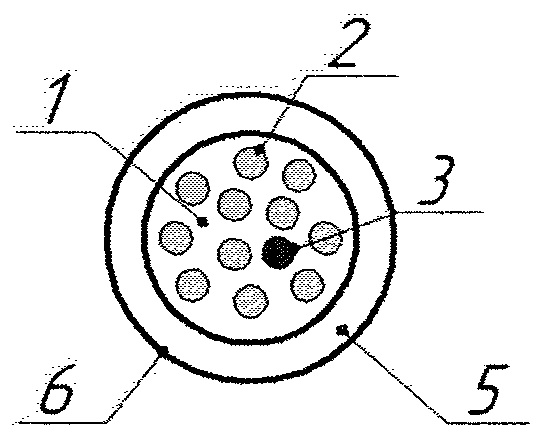

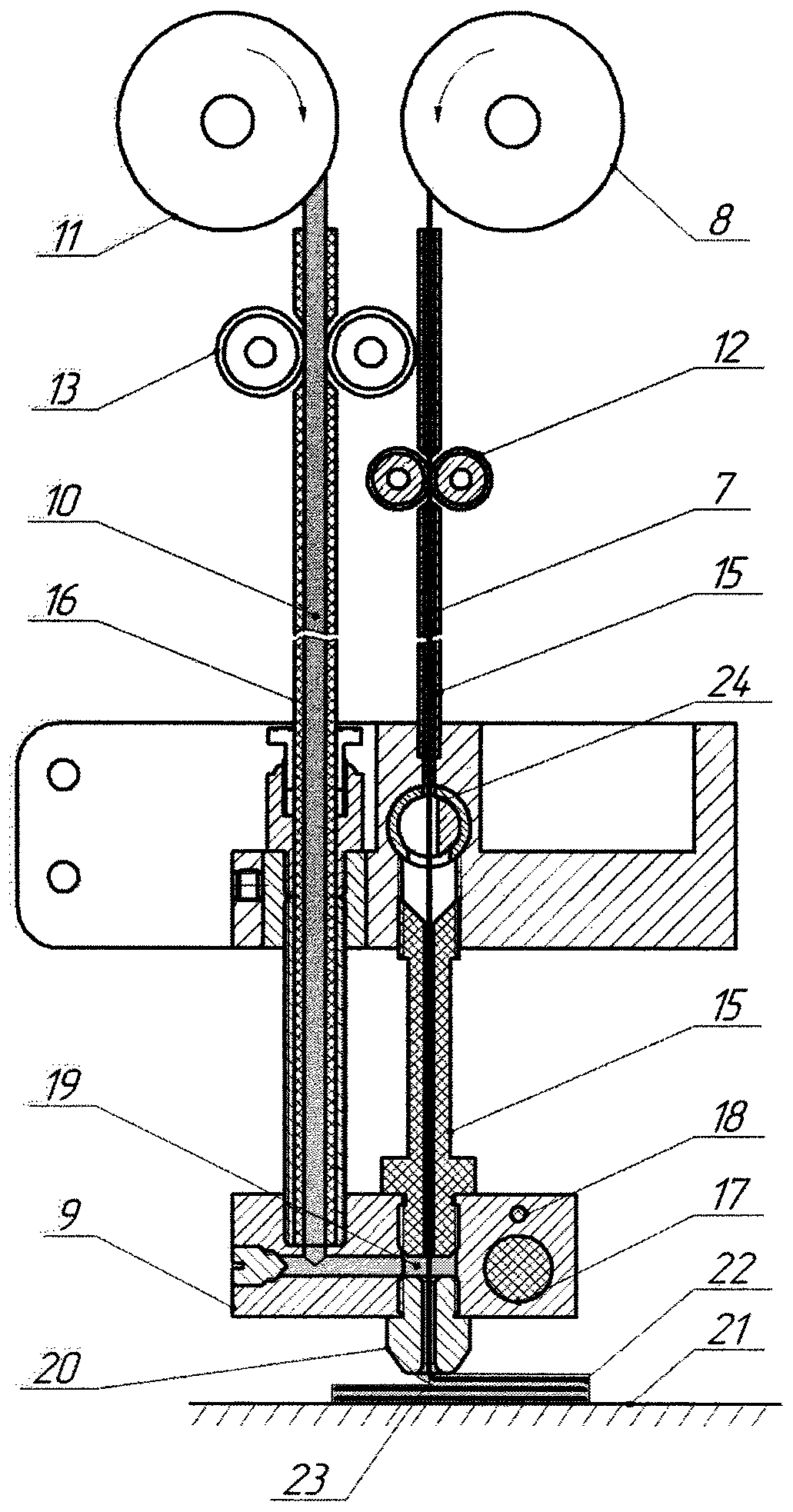

[0076] The created 3D printing method is based on the use of composite fibers ( Figure 1A ). The composite fibers 4 are fiber bundles impregnated with the matrix material 1 and hardened. The fiber bundle may comprise continuous reinforcing fibers 2, such as carbon, glass, aramid, basalt, boron, metal fibers, and functional fibers 3, such as optical fibers and / or conductive fibers, such as copper fibers. The fiber bundle may comprise different numbers of fibers, for example 2, 100, 1000, 3000, 6000, etc. Matrix material 1 for injection is based on phenol formaldehyde, polyester, epoxy, silicone, polyimide, bismaleimide and other adhesive materials, or thermosetting binders with thermoplastic A thermosetting plastic (thermoset) that is a mixture of binders. Thermosetting plastics have good processing properties, especially low viscosity and good adhesion to any type of reinforcing fiber currently in use, allowing good impregnation of reinforcing fiber bundles with the matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com