Composite vacuum insulation board for building exterior wall and preparation method thereof

A technology for vacuum thermal insulation panels and building exterior walls, applied in thermal insulation, construction, building components, etc., can solve the problems of inability to solve the bonding problem of the decorative layer and the lack of protective measures for the thermal insulation board, and achieve excellent thermal insulation effect and stable thermal conductivity. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

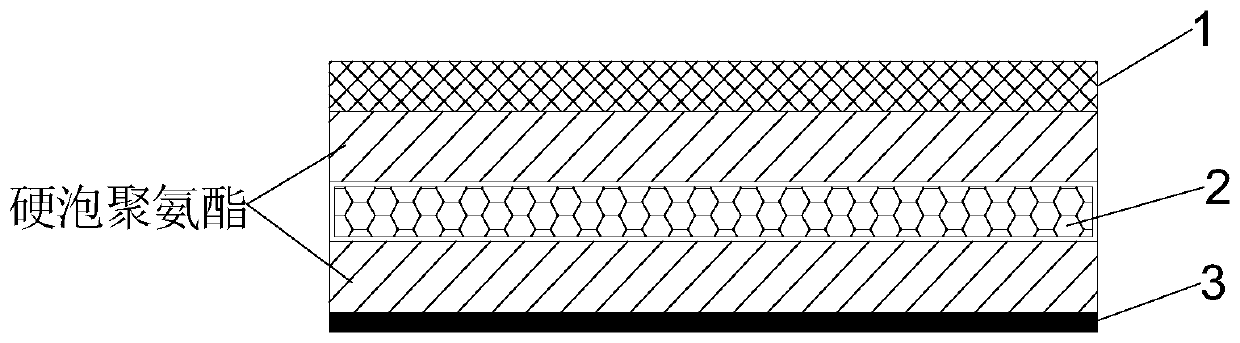

[0051] This embodiment provides a composite vacuum insulation board for building exterior walls, the structure schematic diagram is as follows figure 1 As shown, it includes a surface layer 1, a vacuum insulation panel 2 and a substrate layer 3 arranged in sequence; the two sides of the vacuum insulation panel 2 connected to the surface layer 1 and the substrate layer 3 are independently provided with rigid polyurethane foam layers.

[0052] The thickness of the rigid polyurethane foam layer between the vacuum insulation panel 2 and the surface layer 1 is 25mm; the thickness of the rigid polyurethane foam layer between the vacuum insulation panel 2 and the base layer 3 is 20mm.

[0053] The surface layer 1 is a ceramic plate; the base material layer 3 is a cement-based coil layer; the vacuum insulation panel 2 includes a ceramic fiber insulation core material and an aluminum-plastic composite film coated with a ceramic fiber insulation core material, ceramic fiber Vacuum is dr...

Embodiment 2

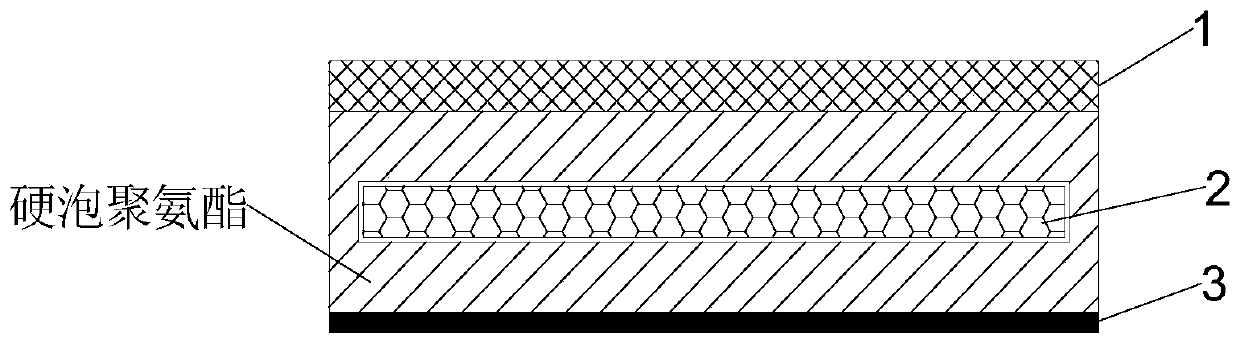

[0057] This embodiment provides a composite vacuum insulation panel for building exterior walls, including a surface layer 1, a vacuum insulation panel 2, and a substrate layer 3 arranged in sequence; the vacuum insulation panel 2 is connected to the surface layer 1 and the substrate layer 3 The two sides of the board are independently provided with hard foam polyurethane layers.

[0058] The thickness of the rigid polyurethane foam layer between the vacuum insulation panel 2 and the surface layer 1 is 15mm; the thickness of the rigid polyurethane foam layer between the vacuum insulation panel 2 and the base layer 3 is 30mm.

[0059] The surface layer 1 is a cement fiber board; the base material layer 3 is a polymer cement layer; the vacuum insulation panel 2 includes a ceramic fiber insulation core material and a composite film coated with a ceramic fiber insulation core material, and the ceramic fiber insulation core material Vacuum is drawn between the composite film and th...

Embodiment 3

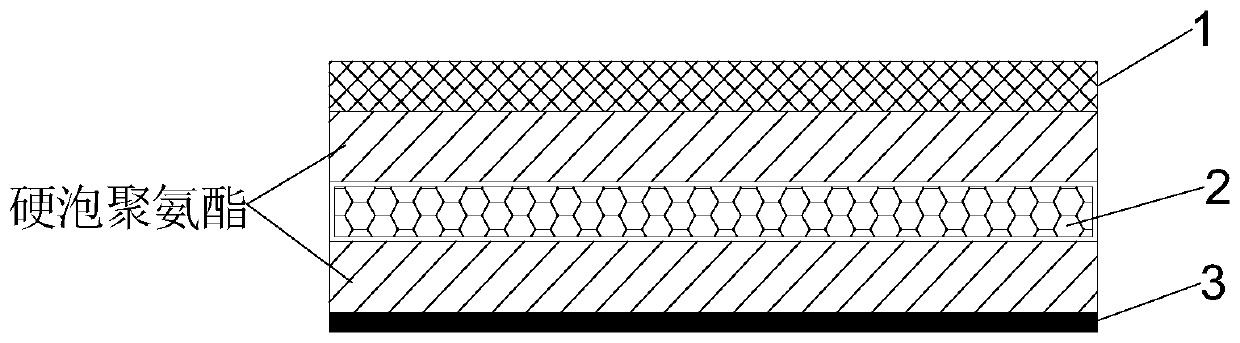

[0063] This embodiment provides a composite vacuum insulation panel for building exterior walls, including a surface layer 1, a vacuum insulation panel 2, and a substrate layer 3 arranged in sequence; the vacuum insulation panel 2 is connected to the surface layer 1 and the substrate layer 3 The two sides of the board are independently provided with hard foam polyurethane layers.

[0064] The thickness of the rigid polyurethane foam layer between the vacuum insulation panel 2 and the surface layer 1 is 1 mm; the thickness of the rigid polyurethane foam layer between the vacuum insulation panel 2 and the base layer 3 is 1 mm.

[0065] The surface layer 1 is a calcium silicate board; the base material layer 3 is a glass fiber mesh cloth layer; the vacuum insulation panel 2 includes a microporous polyurethane insulation core material, aluminum plastic coated microporous polyurethane insulation core material The composite membrane and the getter calcium oxide arranged in the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com