Organic-inorganic hybrid film forming agent, microcapsule type high-temperature self-repairing basalt fiber water-based impregnating agent and preparation method of microcapsule type high-temperature self-repairing basalt fiber water-based impregnating agent

A technology of basalt fiber and microcapsules, which is applied in the field of wetting agent, can solve the problems of losing wetting agent, poor temperature resistance, and hindering the high-temperature performance advantages of basalt fiber, so as to improve high-temperature interface performance, high-temperature resistance, and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

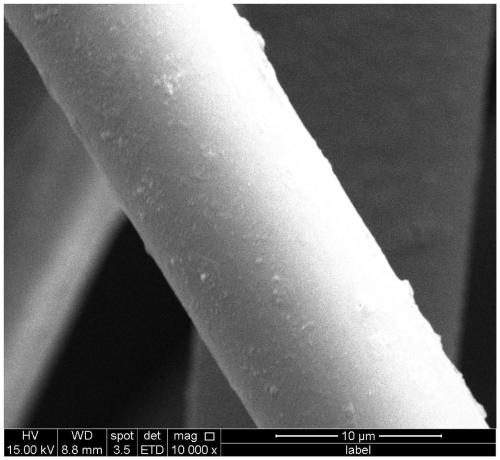

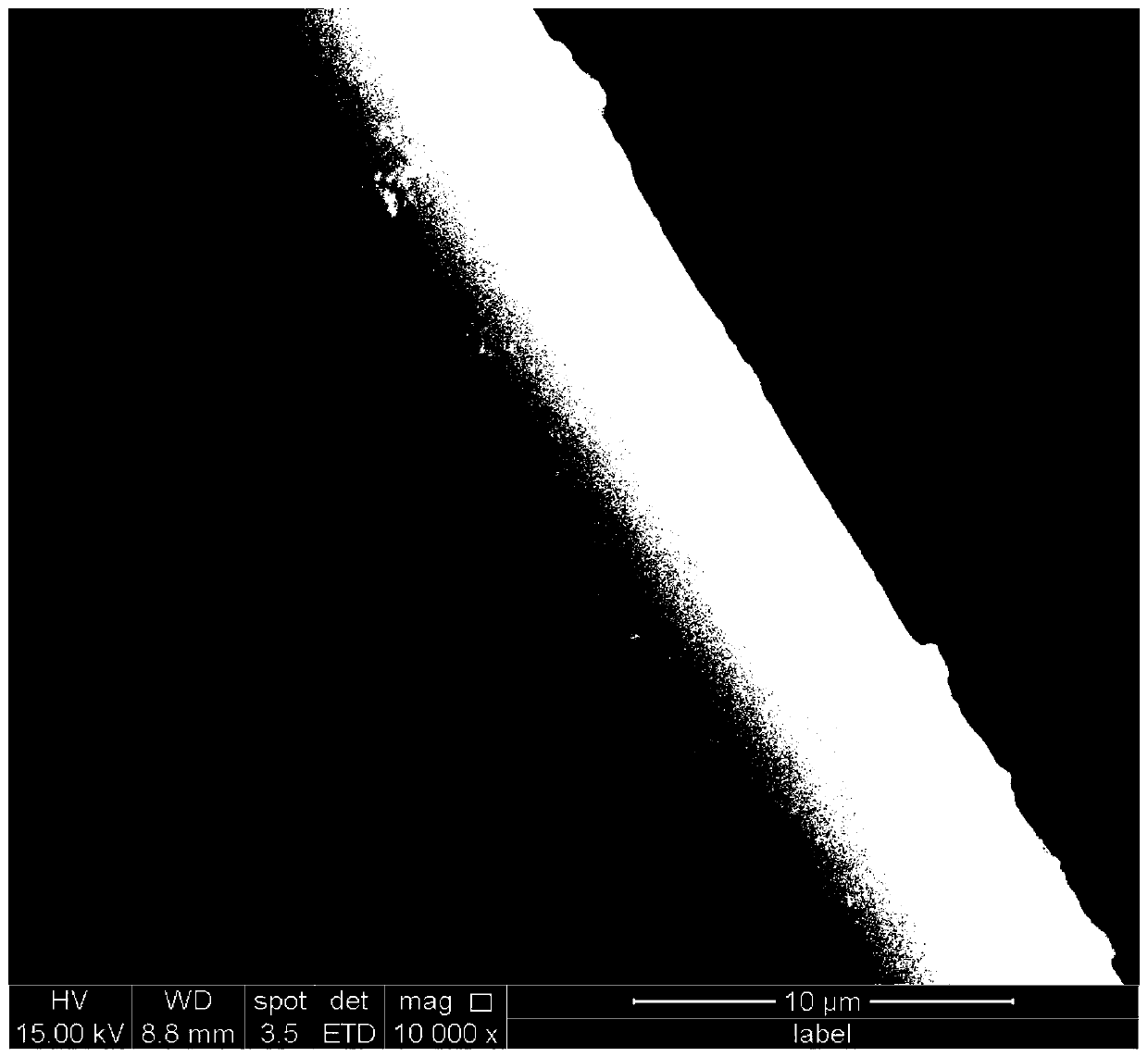

Image

Examples

Embodiment 1

[0021] This example provides an organic-inorganic hybrid film-forming, microcapsule-type high-temperature self-repairing basalt fiber water-based wetting agent, which is made of the following components and their mass parts:

[0022] Methylphenyl silicone resin emulsion (solid phase content: 50%): 28%;

[0023] Environmental protection low-temperature molten glass powder (100-500mm): 20%;

[0024] Talc powder: 5%;

[0025] Mica powder: 4%;

[0026] Coupling agent KH-550: 1%;

[0028] Water: balance.

[0029]Among them, the environmentally friendly low-temperature molten glass powder is a mixture of 400°C low-temperature molten glass powder, 450°C low-temperature molten glass powder, 500°C low-temperature molten glass powder and 580°C low-temperature molten glass powder, and the mass ratio is 4:3:2:1.

[0030] The preparation method of organic-inorganic hybrid film-forming, microcapsule-type high-temperature self-repairing basalt fiber water-...

Embodiment 2

[0034] This example provides an organic-inorganic hybrid film-forming, microcapsule-type high-temperature self-repairing basalt fiber water-based wetting agent, which is made of the following components and their mass parts:

[0035] Methylphenyl silicone resin emulsion (solid phase content: 55%): 15%;

[0036] Environment-friendly low-temperature molten glass powder (100-500mm): 10%;

[0037] Talc powder: 3%;

[0038] Mica powder: 1%;

[0039] Coupling agent KH-550: 0.5%;

[0040] Sodium bentonite: 0.2%;

[0041] Water: balance.

[0042] Among them, the environmentally friendly low-temperature molten glass powder is a mixture of 400°C low-temperature molten glass powder, 450°C low-temperature molten glass powder, 500°C low-temperature molten glass powder and 580°C low-temperature molten glass powder, and the mass ratio is 4:3:2:1.

[0043] The preparation method of organic-inorganic hybrid film-forming, microcapsule-type high-temperature self-repairing basalt fiber water...

Embodiment 3

[0046] This example provides an organic-inorganic hybrid film-forming, microcapsule-type high-temperature self-repairing basalt fiber water-based wetting agent, which is made of the following components and their mass parts:

[0047] Methylphenyl silicone resin emulsion (solid phase content: 40%): 25%;

[0048] Environment-friendly low-temperature molten glass powder (100-500mm): 15%;

[0049] Talc powder: 4%;

[0050] Mica powder: 3%;

[0051] Coupling agent KH-550: 1%;

[0052] Sodium bentonite: 0.8%;

[0053] Water: balance.

[0054] Among them, the environmentally friendly low-temperature molten glass powder is a mixture of 400°C low-temperature molten glass powder, 450°C low-temperature molten glass powder, 500°C low-temperature molten glass powder and 580°C low-temperature molten glass powder, and the mass ratio is 4:3:2:1.

[0055] The preparation method of organic-inorganic hybrid film-forming, microcapsule-type high-temperature self-repairing basalt fiber water-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com