Preparation method of composite catalyst for hydrogen production by photolysis of water

A technology of composite catalyst and photolysis of water to produce hydrogen, which is applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., and can solve problems such as limited improvement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] First measure 12ml of aqueous ammonia solution (25%, mass concentration) and add it to 100ml of nickel nitrate aqueous solution, then add 100ml of urea aqueous solution, stir and mix, heat and react in a water bath at 90°C for 3h, after the reaction is over, filter and wash to recover the precipitate, and The recovered precipitate was calcined at 400°C for 2 hours to prepare NiO hollow microspheres; the molar ratio of nickel nitrate to urea in the nickel nitrate aqueous solution and the urea aqueous solution was 1:2;

[0017] Graphene oxide is added in 200ml alcoholic solution (50%, mass concentration), ultrasonic dispersion mixes, and then adds Ti 3 C 2 Nano-powder, ultrasonically dispersed and mixed, prepared to obtain A solution, Ti in A solution 3 C 2 The content of 0.5mg / ml, the content of graphene oxide is 3.0mg / ml;

[0018] Measure the above-mentioned A solution of 30ml, take by weighing 2.42g of sodium molybdate (Na 2 MoO 4 2H 2 (2), 1.5g NiO hollow micros...

Embodiment 2

[0021] First measure 12ml of aqueous ammonia solution (25%, mass concentration) and add it to 100ml of nickel nitrate aqueous solution, then add 100ml of urea aqueous solution, stir and mix, heat and react in a water bath at 90°C for 3h, after the reaction is over, filter and wash to recover the precipitate, and The recovered precipitate was calcined at 400°C for 2 hours to prepare NiO hollow microspheres; the molar ratio of nickel nitrate to urea in the nickel nitrate aqueous solution and the urea aqueous solution was 1:2;

[0022] Graphene oxide was added in 200ml alcohol solution (50%, mass concentration), and ultrasonically dispersed and mixed to prepare A solution. The content of graphene oxide in A solution was 3.0mg / ml;

[0023] Measure the above-mentioned A solution of 30ml, take by weighing 2.42g of sodium molybdate (Na 2 MoO 4 2H 2 (2), 1.5g NiO hollow microspheres are dropped into the inside successively, ultrasonically dispersed and mixed, then add 3.5g of thiour...

Embodiment 3

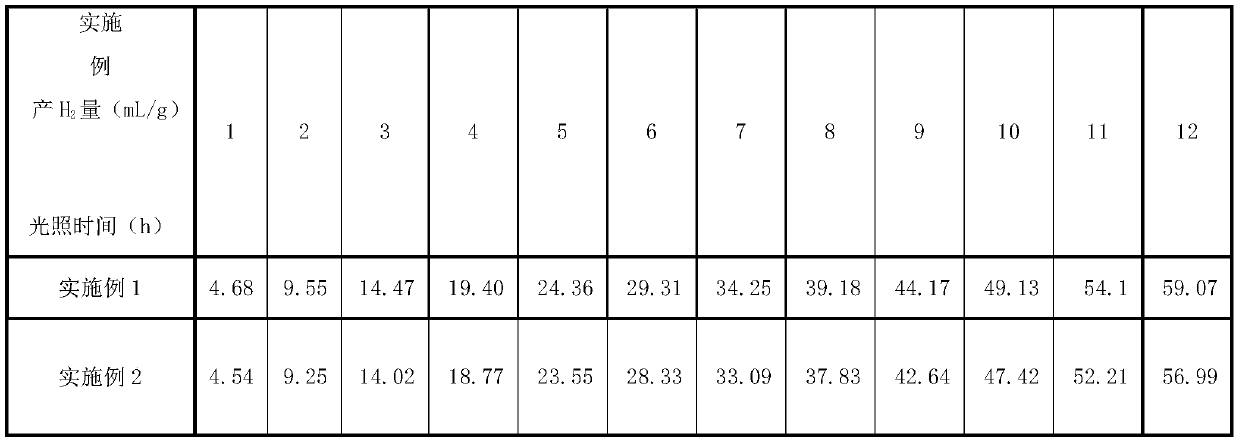

[0026] The performance of the composite catalysts prepared in the above examples 1 and 2 was tested on the MC-SPH2O automatic photocatalytic total water splitting experimental test system. Assemble the composite catalysts prepared in Examples 1 and 2 into the photolysis water system respectively; pass high-purity nitrogen gas for 30 minutes, remove the dissolved oxygen in the reaction system and the air in the pipeline; check the system, turn on the constant temperature circulating water, and start Xenon lamp light source (power 300W), UV light was filtered out with CUT400, and the photocatalytic hydrogen production activity of the composite catalyst was tested for 12 hours of light irradiation. The hydrogen content was detected online by an on-line gas chromatograph, a TCD detector, and a TDX-01 gas-phase packed column. The results of hydrogen production by photolysis of water are shown in Table 1.

[0027] Table 1 Catalyst visible light photolysis of water hydrogen productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com