Production method for wheat flour with low bacteria

A production method and technology for wheat flour, which are applied in grain milling, agriculture, grain processing, etc., to achieve the effects of reducing wheat moistening time, reducing the amount of bacteria, and ensuring aseptic state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

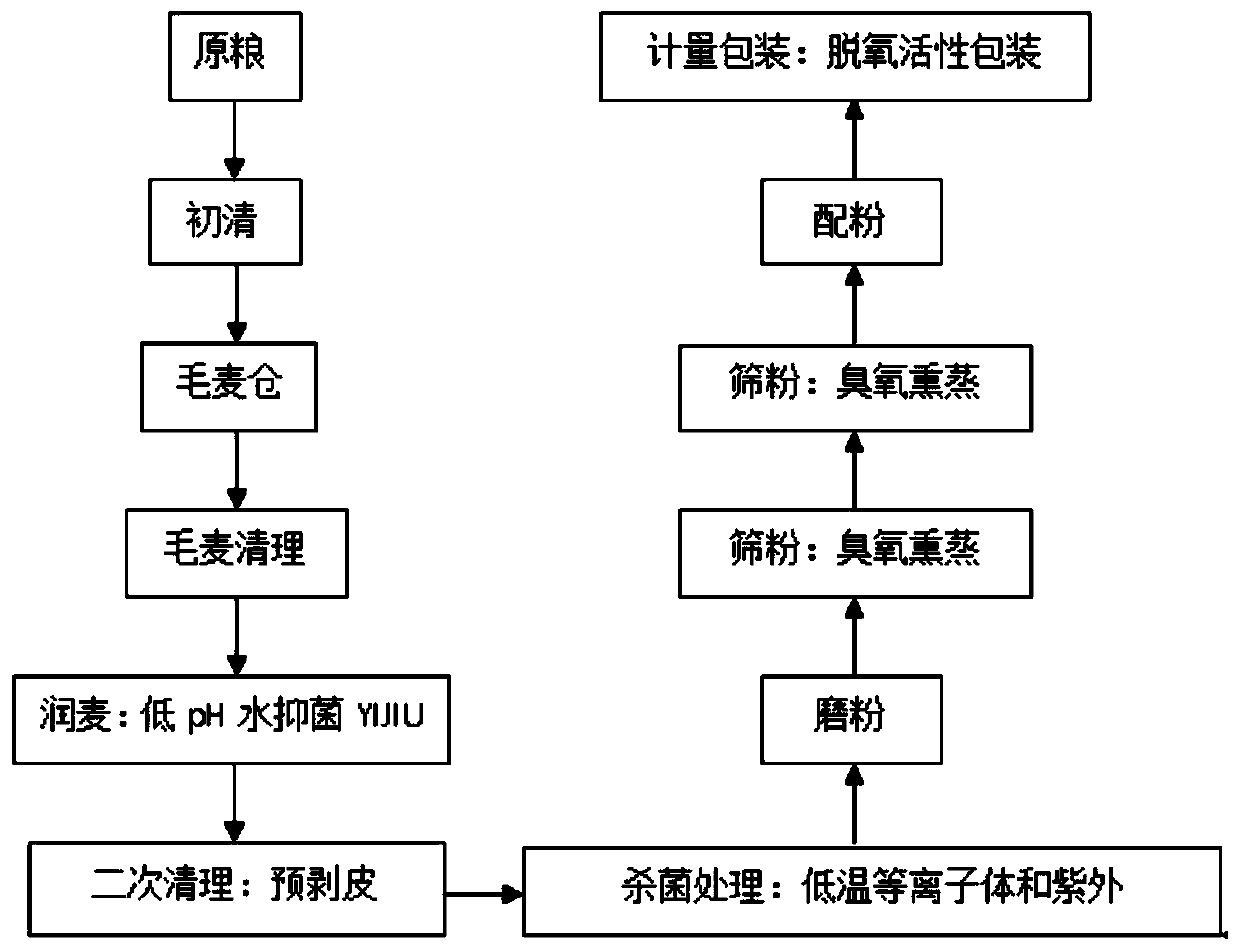

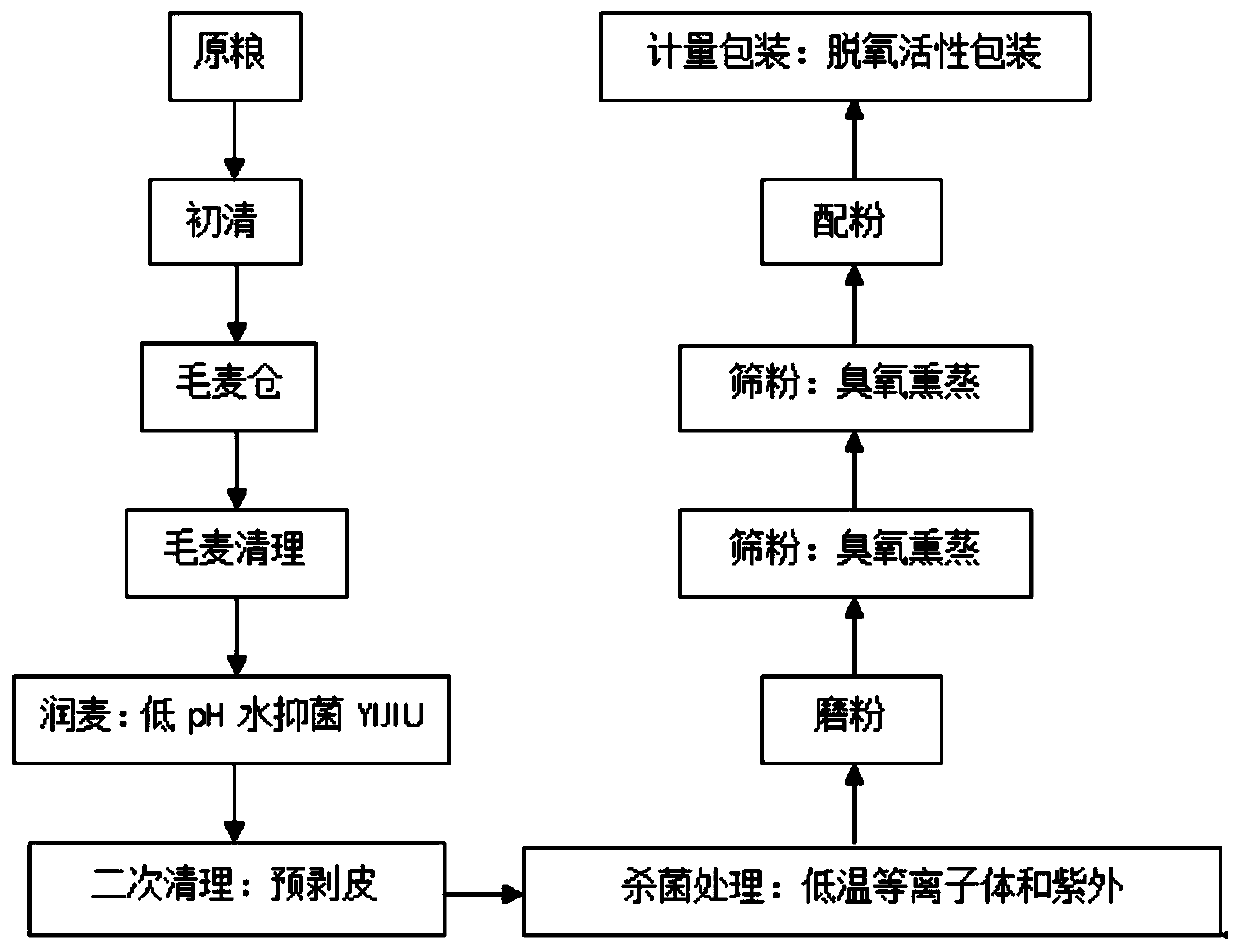

Method used

Image

Examples

Embodiment 1

[0038] The production method of the low-bacteria wheat flour of the present embodiment comprises the steps:

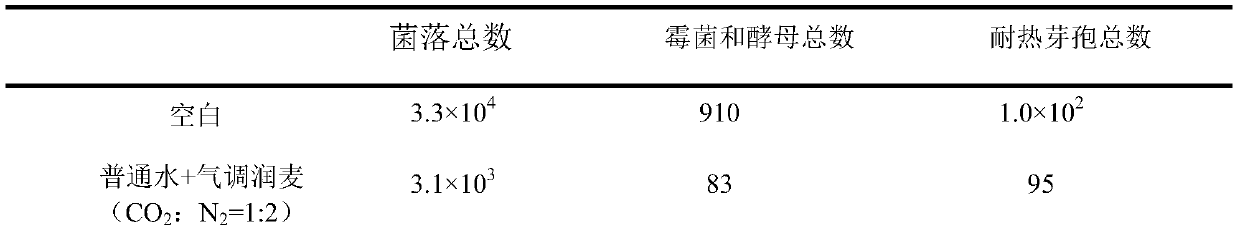

[0039] (1) Pretreatment: Send 1000t of purchased wheat into the wool wheat warehouse through the conveying equipment, use the air conditioning device to replace the original gas in the wool wheat warehouse, and fill it with CO 2 :N 2 = 1:4 air conditioning, and control the temperature and humidity at 10°C and 30% respectively, and the storage time is 4 months;

[0040] (2) Perform primary cleaning of the wheat in (1), including two stages of sieving, one stage of stone removal, one stage of magnetic separation, three stages of threshing and three stages of winnowing, specifically including wool wheat → screening → winnowing → stone removal →Sifting→Magnetic separation→Threshing→wind selection→threshing→wind separation→threshing→clean wheat warehouse;

[0041] (3) Moisten the wheat cleaned in (2), using a low-pH sterile aqueous solution with a pH of 4.8, prepared from...

Embodiment 2

[0049] The production method of the low-bacteria wheat flour of the present embodiment comprises the steps:

[0050] (1) Pretreatment: Send 1000t of purchased wheat into the wool wheat warehouse through the conveying equipment, use the air conditioning device to replace the original gas in the wool wheat warehouse, and fill it with CO 2 :N 2 = 2:3 air conditioning, and control the temperature and humidity at 15°C and 40% respectively, and the storage time is 6 months;

[0051] (2) Perform primary cleaning of the wheat in (1), including two stages of sieving, one stage of stone removal, one stage of magnetic separation, three stages of threshing and three stages of winnowing, specifically including wool wheat → screening → winnowing → stone removal →Sifting→Magnetic separation→Threshing→wind selection→threshing→wind separation→threshing→clean wheat warehouse;

[0052] (3) Moisten the wheat cleaned in (2), using a low-pH sterile aqueous solution with a pH of 5.3, prepared from...

Embodiment 3

[0060] The production method of the low-bacteria wheat flour of the present embodiment comprises the steps:

[0061] (1) Pretreatment: Send 1000t of purchased wheat into the wool wheat warehouse through the conveying equipment, use the air conditioning device to replace the original gas in the wool wheat warehouse, and fill it with CO 2 :N 2 = 4:1 air conditioning, and controlled temperature and humidity are 20 ℃ and 50%, storage time is 8 months;

[0062] (2) Perform primary cleaning of the wheat in (1), including two stages of sieving, one stage of stone removal, one stage of magnetic separation, three stages of threshing and three stages of winnowing, specifically including wool wheat → screening → winnowing → stone removal →Sifting→Magnetic separation→Threshing→wind selection→threshing→wind separation→threshing→clean wheat warehouse.

[0063] (3) Moisten the wheat cleaned in (2), using a low-pH sterile aqueous solution with a pH of 6.0, prepared from citric acid, malic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com