Water-injected compressor

A compressor and water injection technology, applied in mechanical equipment, machines/engines, liquid variable volume machinery, etc., to prevent reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

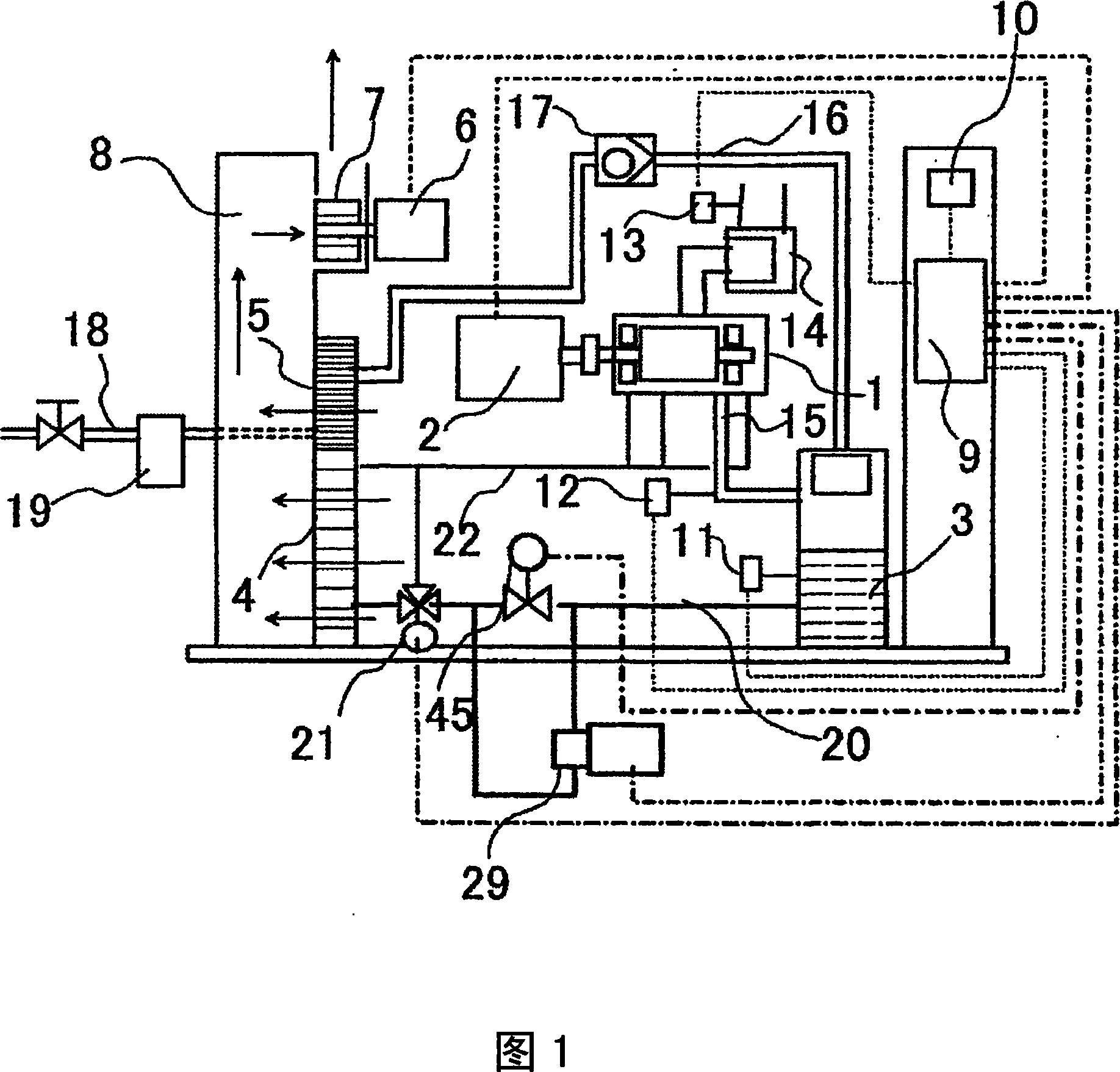

[0020] FIG. 1 shows a system configuration of a water jet compressor according to an embodiment. The compressor unit 1 is a positive displacement compressor, and a screw compressor will be described as an example.

[0021] The water in the separator 3 is supplied to the compressor 1 from the water supply pipe 20 connected to the separator 3 by the internal pressure of the separator 3 . The water cooled by the air-cooled water cooler 4 connected to the water supply pipe 20 is supplied from the water injection pipe 22 to the rotor working chamber of the compressor unit 1 . When the bearing of the compressor is a water-lubricated bearing, since there is no pressure to send out water in the separator 3 when the compressor unit 1 is started, the pump 29 installed between the water supply pipe 20 and the air-cooled water cooler 4 Start up, pressurize the water from the separator 3, and supply the water to the bearing of the compressor part 1.

[0022] The compressor part 1 compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com