A kind of superhydrophobic composite material with fluorinated epoxy resin as matrix, preparation method and superhydrophobic surface

A technology of epoxy resin and composite material, which is applied in the fields of superhydrophobic surface, preparation, and superhydrophobic composite material, which can solve the problems of weak superhydrophobic surface, difficult to work, and difficult to repeat the formation of rough texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

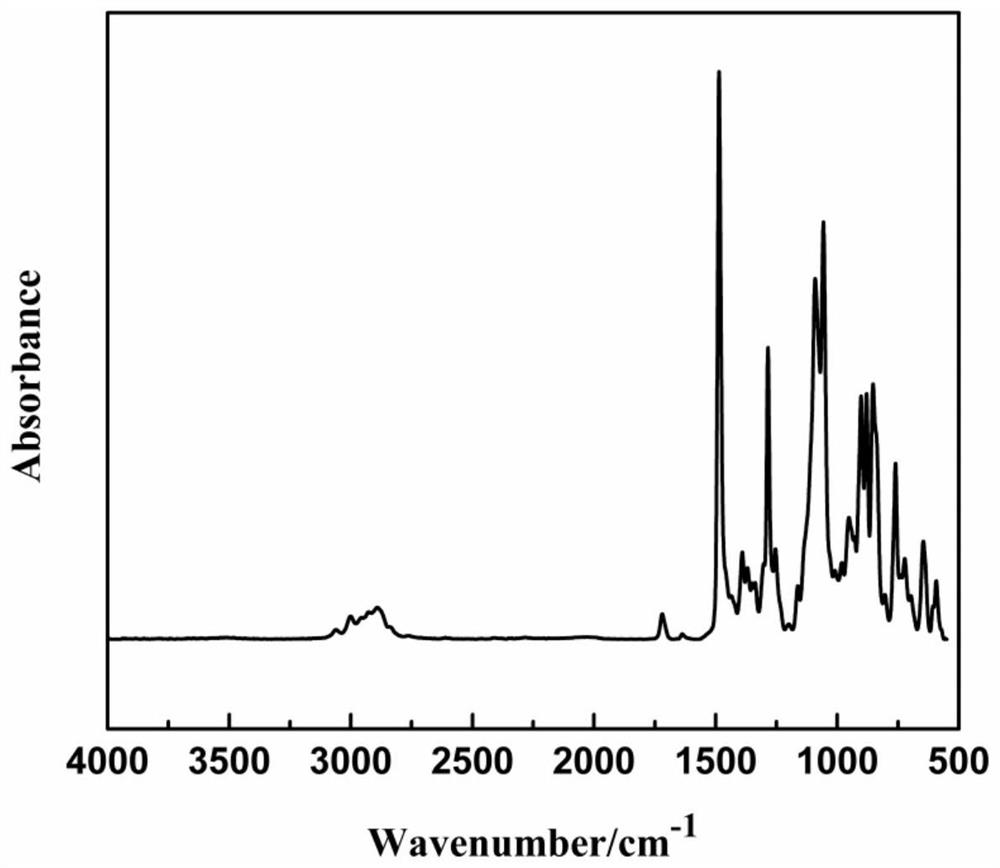

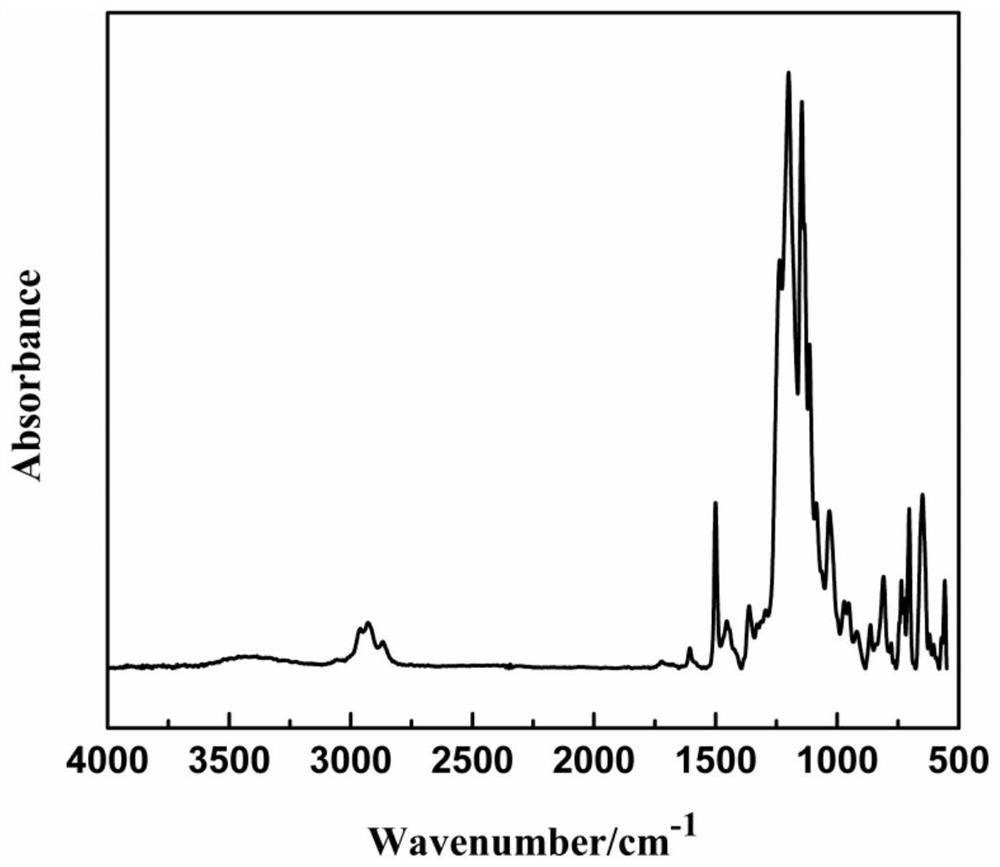

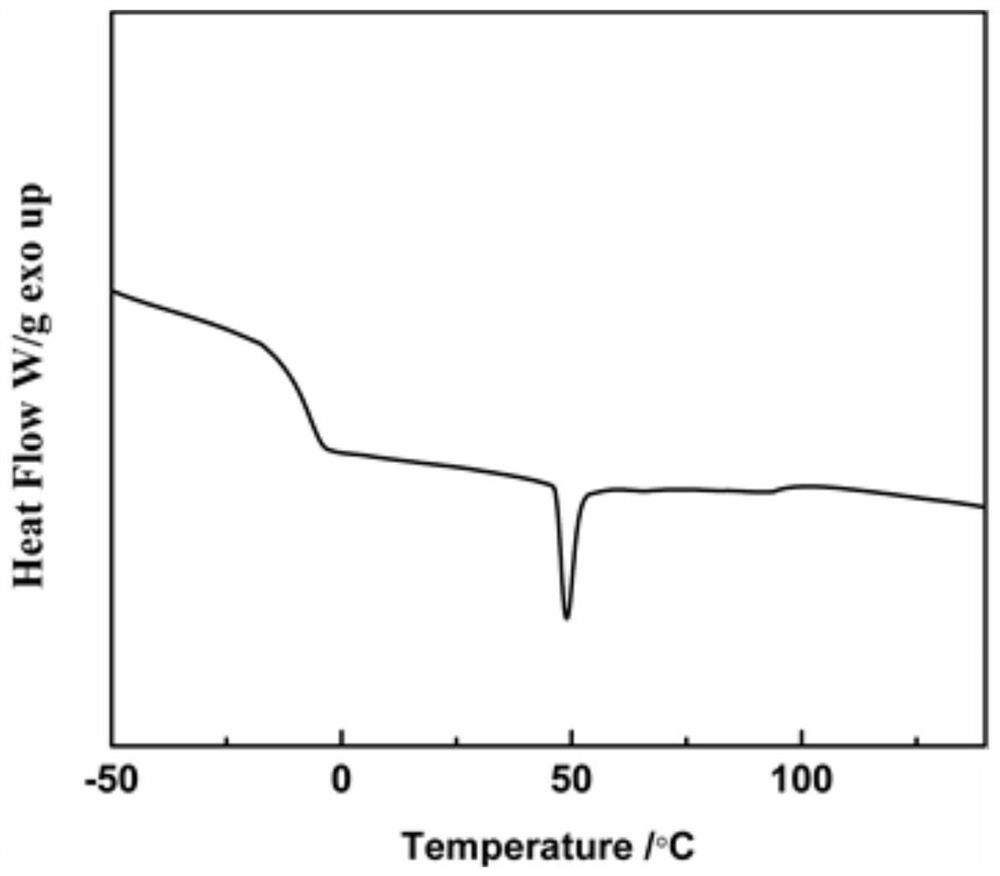

[0044] (1) Add 22g of 2,3,5,6-tetrafluoro-tere-phenylenedimethanol, 15g of sodium hydroxide and 100g of epichlorohydrin into a 500ml three-neck flask, stir at room temperature for 20 minutes, then add 0.5 tetramethylammonium bromide g, heated up to 65°C and reacted for 120 minutes, washed with water and distilled to obtain FEP 1; Then add 5g 4,4'-diallyl bisphenol A type epoxy resin, 2.3g 1H,1H,2H,2H-perfluorodecanethiol, 0.08g photoinitiator 1173 and 3g tetrahydrofuran, under the irradiation of a 365nm UV-LED surface light source, reacted at room temperature for 3 hours, removed the solvent, and obtained FEP 2 . The reaction product can be seen by infrared figure 1 and figure 2 . FEP 2 The melting point was determined by DSC, see image 3 .

[0045] (2) First, add 2.1g of nano-silica with a particle size of 500nm and 4.2g of nano-silica with a particle size of 50nm after KH550 treatment into 20g of ethanol for 15 minutes of ultrasonication, then magnetically stir for ...

Embodiment 2

[0054] (1) Add 11g of 2,3,5,6-tetrafluoro-tere-phenylenedimethanol, 7g of sodium hydroxide and 70g of epichlorohydrin into a 250ml three-neck flask, stir at room temperature for 30 minutes, then add tetramethylammonium bromide 0.2 g, after heating up to 70°C, it generates heat by its own reaction, and the reaction temperature is maintained at 70°C for 130 minutes, and FEP is obtained after washing with water and distillation 1 ; Then add 10g 4-4'-diallyl bisphenol A epoxy resin, 4.6g 1H, 1H, 2H, 2H-perfluorodecanethiol, 0.2g photoinitiator 184 and 8g tetrahydrofuran, under the irradiation of 365nm UV-LED surface light source, react at room temperature for 3 hours, remove solvent, obtain FEP 2 .

[0055] (3) First add 1g of nano-silica with a particle size of 500nm and 2g of nano-silica with a particle size of 30nm after KH560 treatment into 15g of ethanol and sonicate for 20min, then magnetically stir for 20min to obtain a suspension, and then add 4gFEP 1 , 1gFEP 2 Add it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com