Battery bionic heat dissipation and heat recovery system and implementation method thereof

A bionic shape and heat recovery technology, which is applied in the direction of secondary batteries, electrochemical generators, battery circuit devices, etc., can solve the problem that lithium batteries are derived from lithium batteries, do not consider the independent individual of the battery, and reduce the utilization rate of the battery and other issues to achieve the effect of reducing heat dissipation loss, reducing adverse effects, reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

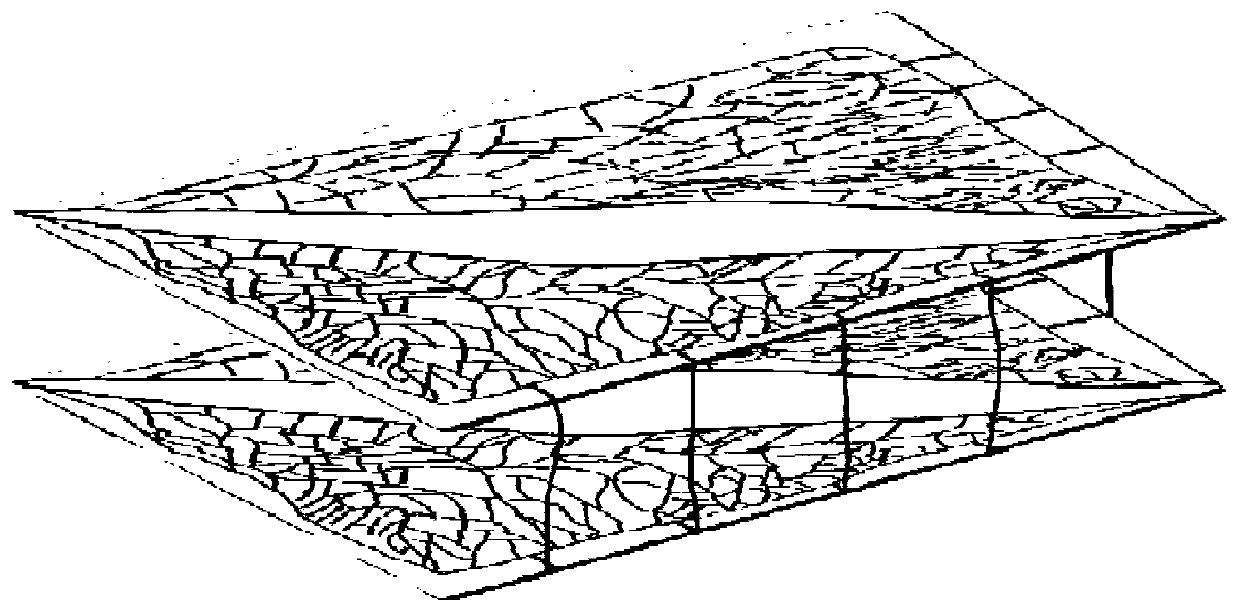

[0036] Such as Figure 1~3 As shown, a battery bionic heat dissipation and heat recovery system includes a porous medium module containing a porous medium composite phase change material 2, a honeycomb-shaped ultra-thin gravity heat pipe 3 heat dissipation module, a tree root-like heat transfer module, based on Thermoelectric conversion module of Seebeck effect, imitation capillary microchannel radiator 9 and charging energy storage module 8, wherein:

[0037] The porous medium of the porous medium module has excellent porous properties, and the porous medium adopts expanded graphite, which has good compatibility with phase change material (PCM) paraffin, and the paraffin is adsorbed in the micropores to make a porous medium composite phase change material 2. The therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com