Silicon micro-gyroscope data acquisition device based on wireless transmission

A silicon micro-gyroscope and data acquisition technology, applied in gyroscope/steering sensing equipment, measuring device, gyro effect for speed measurement, etc., can solve uneven temperature distribution, gyroscope output signal error, slip ring frosting, etc. problem, achieve the effects of reducing uneven temperature distribution, fast and accurate acquisition, and long transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

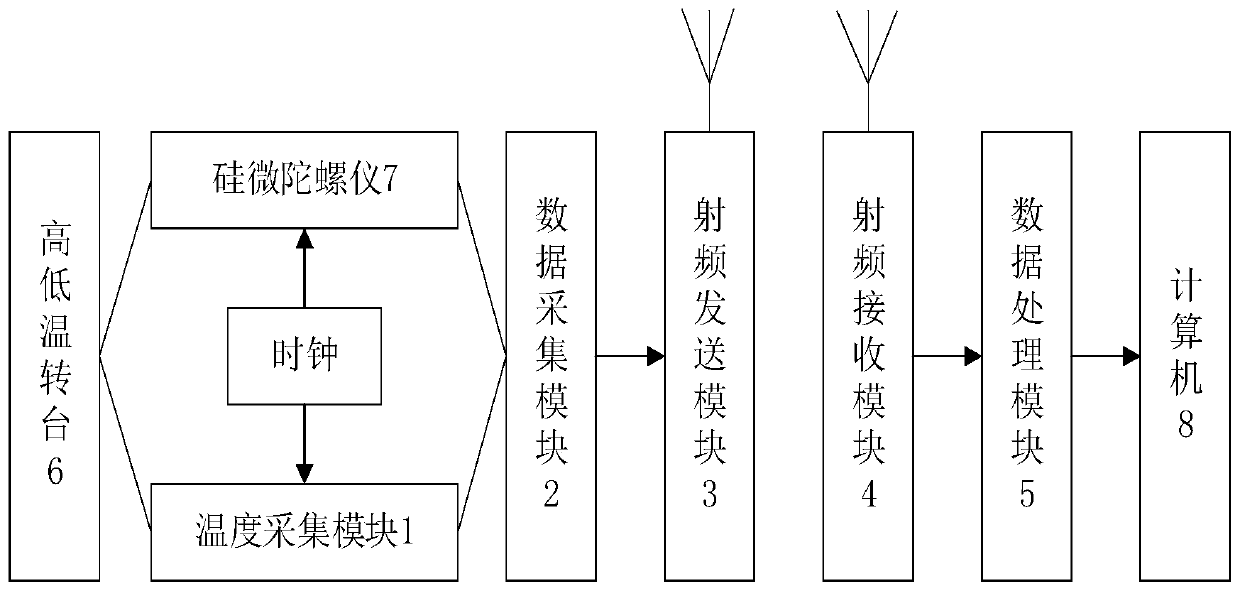

[0027] Such as figure 1 Shown, the present invention is based on the silicon microgyroscope data acquisition device of wireless transmission, comprises:

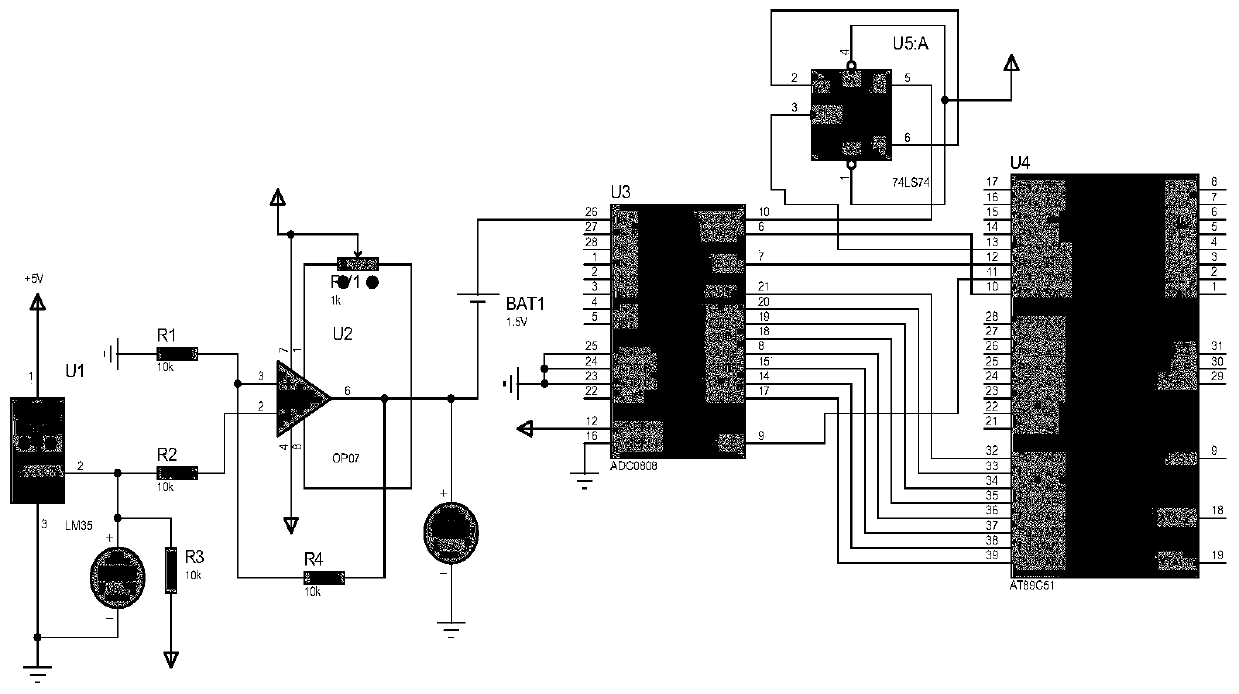

[0028] The temperature acquisition module 1 is used to detect the temperature of the high and low temperature box and collect the real-time temperature of the silicon micro gyroscope;

[0029] The data acquisition module 2 is used to collect the output of the silicon micro gyroscope and the temperature acquisition module, and perform analog-to-digital conversion processing on it;

[0030] The radio frequency sending module 3 is used for modulating the information of the data acquisition module, and converting the modulated signal into a radio frequency signal suitable for wireless transmission;

[0031] The radio frequency receiving module 4 is used for receiving the information transmitted by the radio frequency sending module and demodulating it;

[0032] The data processing module 5 is used to process the information of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com