Sterilization sealant for ceramic tile gap filling and preparation method thereof

A gap filling and beautifying agent technology, applied in the field of beautifying agents, can solve the problems of high price, wear, easy to scratch, etc., achieve the effect of natural and delicate color, excellent comprehensive performance, and avoid excessive hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

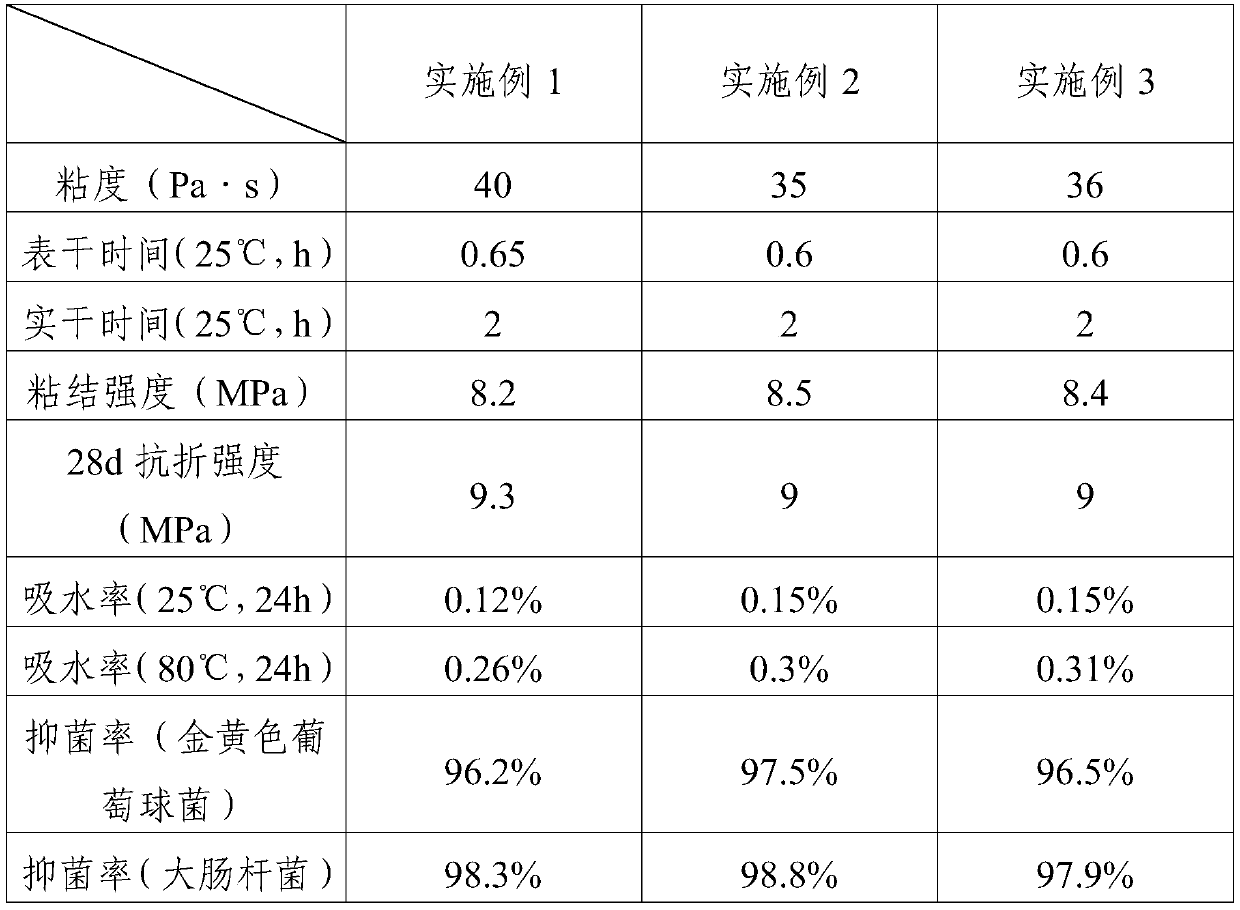

Embodiment 1

[0034] A bactericidal beautifying agent for ceramic tile gap filling, comprising A component and B component with a weight ratio of 10:1, and the A component includes the following components in parts by weight:

[0035] 88 parts of epoxy resin modified styrene-acrylic emulsion, 45 parts of silane-terminated polyether, 22 parts of phthalic anhydride polyester polyol, 10 parts of polytetrahydrofuran, 8 parts of epoxy-containing organosiloxane, 1,2-dicarboxylic acid di 1.5 parts of isononyl ester, 5 parts of acetyl tri-n-butyl citrate, 50 parts of talc powder, 5 parts of carbon black, 35 parts of bentonite, 20 parts of nano attapulgite, 12 parts of hollow glass microspheres, 15 parts of volcanic ash, 2 parts of fungicide HY-606-1, 3 parts of isothiazolinone derivative preservative, 30 parts of reinforcing fiber mixed with glass fiber and aramid fiber at a weight ratio of 1:1, 8 parts of pigment, dilauric acid 3 parts of dibutyltin;

[0036] The B component is epoxy resin amine ...

Embodiment 2

[0040] A bactericidal beautifying agent for ceramic tile gap filling, comprising A component and B component with a weight ratio of 12:1, and the A component includes the following components in parts by weight:

[0041] 100 parts of epoxy resin modified styrene-acrylic emulsion, 47 parts of silane-terminated polyether, 26 parts of phthalic anhydride polyester polyol, 6 parts of polytetrahydrofuran, 10 parts of epoxy-containing organosiloxane, 1,2-dicarboxylic acid di 1 part of isononyl ester, 5 parts of acetyl tri-n-butyl citrate, 45 parts of talc, 7 parts of carbon black, 35 parts of bentonite, 20 parts of nano attapulgite, 12 parts of hollow glass microspheres, 10 parts of volcanic ash, 1.4 parts of fungicide HY-606D, 5 parts of isothiazolinone derivative preservative, 25 parts of reinforcing fiber mixed with glass fiber and aramid fiber at a weight ratio of 5:1, 5 parts of pigment, dibutyltin dilaurate 5 copies;

[0042] The B component is the epoxy resin amine curing age...

Embodiment 3

[0046] A bactericidal beautifying agent for ceramic tile gap filling, comprising A component and B component with a weight ratio of 10:1, and the A component includes the following components in parts by weight:

[0047] 85 parts of epoxy resin modified styrene-acrylic emulsion, 40 parts of silane-terminated polyether, 22 parts of phthalic anhydride polyester polyol, 10 parts of polytetrahydrofuran, 8 parts of epoxy-containing organosiloxane, 1,2-dicarboxylic acid di 1 part of isononyl ester, 4 parts of acetyl tri-n-butyl citrate, 50 parts of talc, 5 parts of carbon black, 36 parts of bentonite, 20 parts of nano attapulgite, 8 parts of hollow glass microspheres, 10 parts of volcanic ash, 2 parts of fungicide HY-606D-2, 4 parts of isothiazolinone derivative preservative, 40 parts of reinforcing fiber mixed with glass fiber and aramid fiber at a weight ratio of 2:1, 5 parts of pigment, dilauric acid 3 parts of dibutyltin;

[0048] The B component is the epoxy resin amine curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com