A method of manufacturing beryllium bronze explosion-proof hammer

A beryllium bronze and beryllium manufacturing technology, applied in the field of explosion-proof tool manufacturing, can solve the problems of coarse structure, high rejection rate, easy cracking, etc., and achieve the effects of uniform and fine grains, high production efficiency, and high effective pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

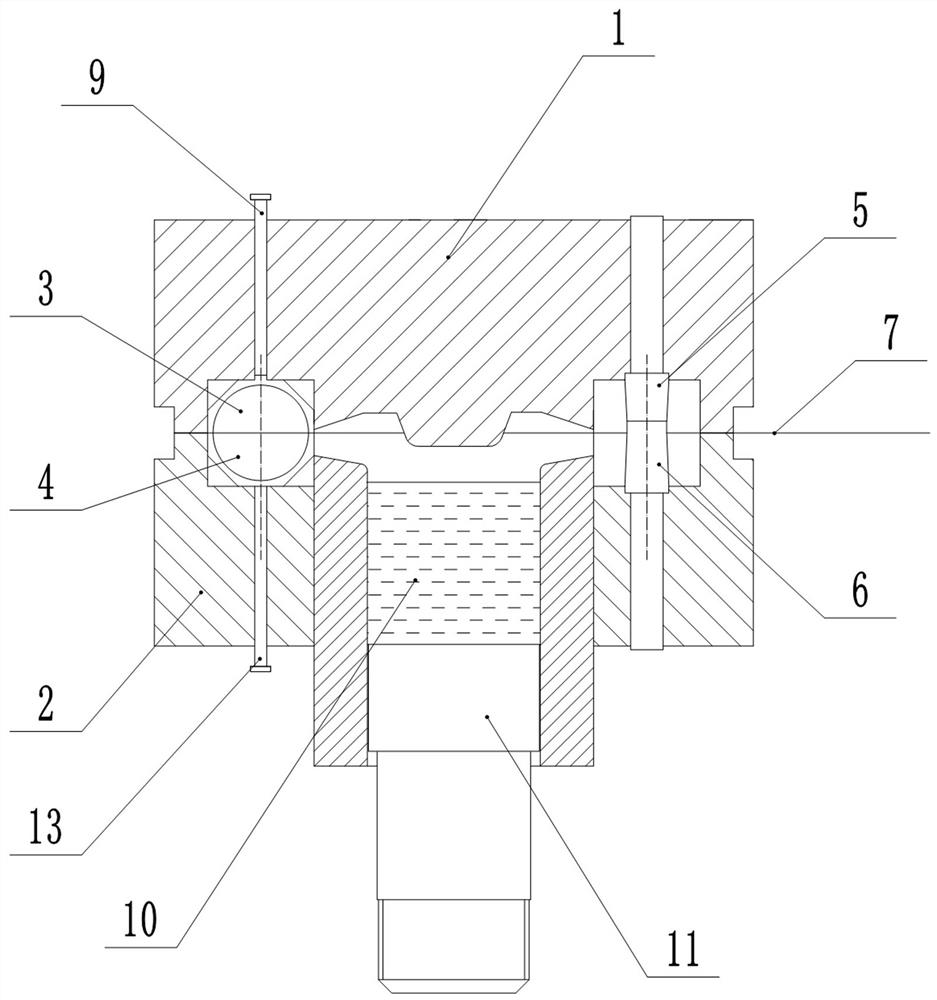

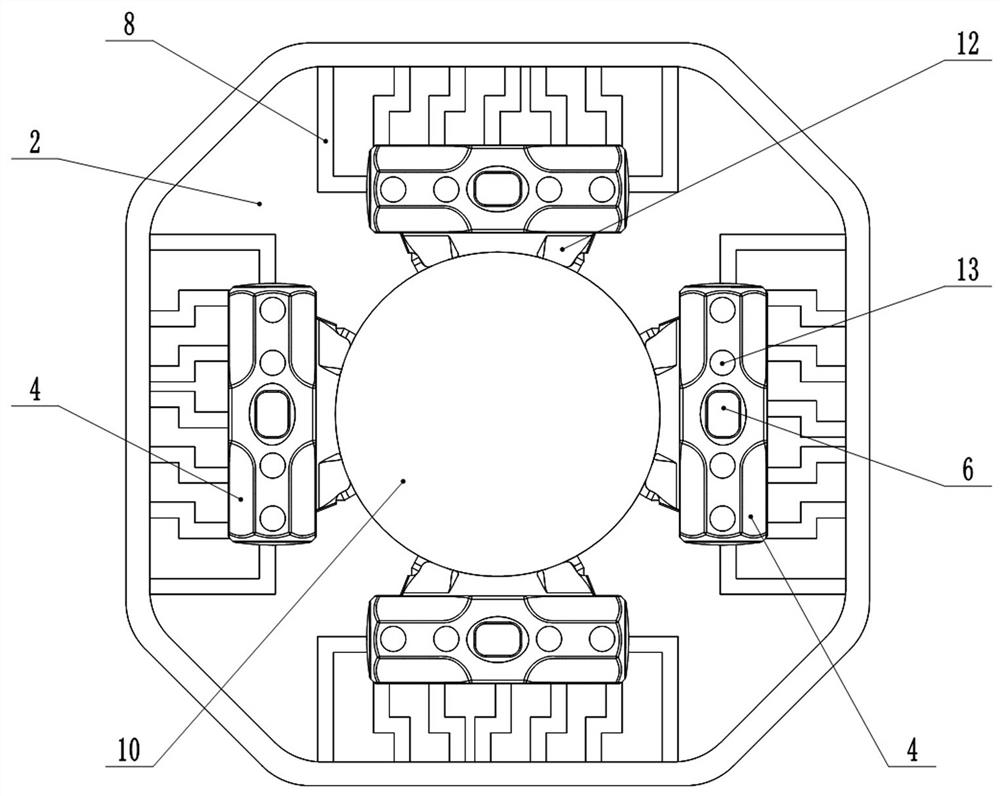

[0040] A metal casting mold for manufacturing beryllium bronze explosion-proof hammer, which includes a horizontally split upper half-type 1 and a lower half-type 2; the upper half-type 1 is provided with an upper mold half cavity 3, and the lower half-type 2 A lower mold half cavity 4 corresponding to the upper mold half cavity 3 is arranged on the upper side, and the upper mold half cavity 3 and the lower mold half cavity 4 are closed to form an explosion-proof hammer head cavity.

[0041] The metal casting mold is made of hot work abrasive steel, and is horizontally parted. The parting surfaces of the upper half and the lower half of the mold are located on the horizontal center plane of the beryllium bronze explosion-proof hammer head.

[0042] The center of the top surface of the upper mold half cavity 3 is provided with an upper half core 5, and the center of the bottom surface of the lower mold half cavity 4 is provided with a lower half core 6, and the upper half core 5...

Embodiment 2

[0050] A kind of method utilizing metal mold in embodiment 1 to manufacture beryllium bronze explosion-proof hammer, it comprises the steps:

[0051] (1) Smelting and processing the beryllium bronze alloy to obtain a beryllium bronze alloy liquid; the beryllium bronze alloy includes the following components in mass percentage: Be 1.80% and the balance Cu, without Ni; the melting temperature is 1200°C.

[0052] (2) Clamping and locking the mold: pour the beryllium bronze alloy liquid into the storage chamber of the lower half mold by gravity within 2 to 5 seconds, close the upper half mold and the lower half mold and pressurize and lock, the pouring temperature It is 1200°C. The applied pressure (N) ≥ the horizontal projected area of the entire cavity (mm 2 ) × 100 (MPa); Pressurized locking mold clamping is to use pressurized equipment to directly compress the upper and lower molds. The pressurizing equipment is a hydraulic press, the nominal force of the main cylinder is ...

Embodiment 3

[0057] A kind of method utilizing metal mold in embodiment 1 to manufacture beryllium bronze explosion-proof hammer, it comprises the steps:

[0058] (1) Smelting and treating the beryllium bronze alloy to obtain a beryllium bronze alloy liquid; the beryllium bronze alloy includes the following components in mass percentage: Be 2.00% and the balance Cu, without Ni; the melting temperature is 1300°C.

[0059] (2) Clamping and locking the mold: pour the beryllium bronze alloy liquid into the storage chamber of the lower half mold by gravity within 2 to 5 seconds, close the upper half mold and the lower half mold and pressurize and lock, the pouring temperature It is 1200°C. The applied pressure (N) ≥ the horizontal projected area of the entire cavity (mm 2 )×160 (MPa).

[0060] (3) Pressurized solidification: within 1-3 seconds after the clamping pressure is added to the set value, the lower pressure head is used to push the beryllium bronze alloy liquid in the material stor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com