Production method of slush-molded silicone rubber artware

A production method and handicraft technology, applied in the production field of slush plastic silicone rubber handicrafts, can solve the problems of human body adverse effects, toxicity, carcinogenicity, etc., and achieve the effects of low density, high resilience and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

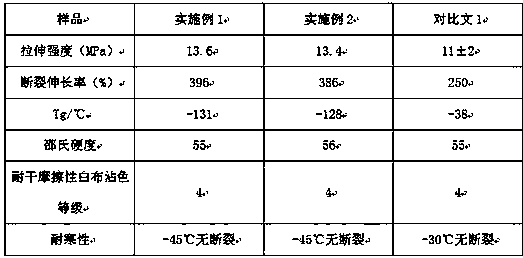

Examples

Embodiment 1

[0020] A kind of production method of plastic slush silicone rubber handicraft comprises the steps:

[0021] (1) In a reaction kettle equipped with a stirrer, a thermometer, a drip inlet, a nitrogen pipe and a reflux device, first add 270 parts of anhydrous xylene and 0.6 part of metal sodium, heat to boiling while stirring under nitrogen, and then Add 100 parts of dimethyldichlorosilane dropwise within 1 hour, keep warm and reflux for 10 hours, a precipitate is formed, filter, wash with methanol first, and then wash with water to obtain white powder polydimethylsilane. In the reaction kettle, add 80 parts of diphenylchlorosilane, 26 parts of boric acid and 4 parts of n-butanol ethyl ether are heated up to 120°C under a nitrogen atmosphere to form a white resin. Then, the temperature is raised to 400°C under vacuum, and the reaction is kept for 1 hour to obtain polyboron Diphenylsiloxane, in the reaction kettle, add 250 parts of polydimethylsilane and 0.125 parts of polyboron ...

Embodiment 2

[0030] A kind of production method of plastic slush silicone rubber handicraft comprises the steps:

[0031] (1) In a reaction kettle equipped with a stirrer, a thermometer, a drip inlet, a nitrogen pipe and a reflux device, first add 270 parts of anhydrous xylene and 0.6 part of metal sodium, heat to boiling while stirring under nitrogen, and then Add 100 parts of dimethyldichlorosilane dropwise within 0.5h, keep warm and reflux for 5h, a precipitate is formed, filter, wash with methanol first, and then wash with water to obtain white powder polydimethylsilane, in the reaction kettle, and then Add 80 parts of diphenylchlorosilane, 26 parts of boric acid and 4 parts of n-butanol ether, raise the temperature to 120°C under a nitrogen atmosphere, and react to form a white resin, then raise the temperature to 400°C under vacuum, and keep it warm for 1 hour to obtain a polymer Borodiphenylsiloxane, in the reaction kettle, add 250 parts of polydimethylsilane and 0.125 parts of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com