High-performance automotive modified polypropylene composite material based on functional POSS hybridization and preparation method thereof

A technology of composite materials and polypropylene, applied in the field of polypropylene, can solve problems such as increasing costs and high performance requirements, and achieve the effect of reducing emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Functional POSS nano-powder modified high-performance polypropylene composite material: according to weight parts, 4 parts of vinyl POSS and 80 parts of polypropylene with a flow rate of 60g / 10min, 5 parts of 3000 mesh talc, 9 parts of elastomer , 1010 antioxidant 0.1 parts, other additives: lubricant white oil, light stabilizer V703 1.9 parts together added to the high-speed mixer and mixed uniformly, then added to the twin-screw extruder, through the twin-screw extruder The machine melts, extrudes, cools, and pellets to prepare a modified polypropylene composite material.

[0027] The processing temperatures in the I-X zones of the twin-screw extruder are 155°C, 180°C, 200°C, 205°C, 215°C, 220°C, 225°C, 225°C, 230°C, and 235°C in sequence. The main screw speed is 550r / min, and the tank temperature is 38°C.

Embodiment 2

[0032] Functional POSS nano-powder modified high-performance polypropylene composite material: according to weight parts, 6 parts of vinyl POSS and 70 parts of polypropylene with a flow rate of 60g / 10min, 10 parts of 3000 mesh talc, 12 parts of elastomer , DSTP antioxidant 0.3 parts, other additives: lubricant white oil, light stabilizer 5589 1.5 parts together added to the high-speed mixer and mixed uniformly, then added to the twin-screw extruder, through the twin-screw extruder The machine melts, extrudes, cools, and pellets to prepare a modified polypropylene composite material.

[0033] The processing temperatures in the I-X zones of the twin-screw extruder are 155°C, 180°C, 200°C, 205°C, 215°C, 220°C, 225°C, 225°C, 230°C, and 235°C in sequence. The main screw speed is 550r / min, and the tank temperature is 38°C.

Embodiment 3

[0038] Functional POSS nano-powder modified high-performance polypropylene composite material: In parts by weight, 10 parts of epoxy-based POSS nano-powder, 70 parts of polypropylene with a flow rate of 30g / 10min, and 10 parts of 3000 mesh talc , 8 parts of elastomer, 0.5 part of DSTP antioxidant, other additives: lubricant white oil, 1.5 parts of light stabilizer 5589 and 1.5 parts are added to the high-speed mixer and mixed uniformly, and then added to the twin-screw extruder. The modified polypropylene composite material is prepared by melting, extruding, cooling and pelletizing through a twin screw extruder.

[0039] The processing temperatures in the I-X zones of the twin-screw extruder are 155°C, 180°C, 200°C, 205°C, 215°C, 220°C, 225°C, 225°C, 230°C, and 235°C in sequence. The main screw speed is 550r / min, and the tank temperature is 38°C.

PUM

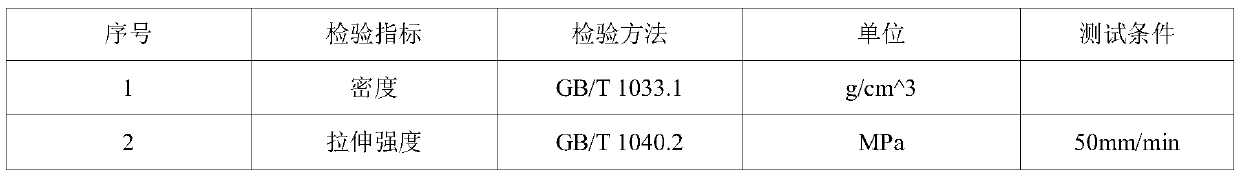

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com