Mirror surface glass fiber reinforced plastic plate, preparation device and preparation method thereof

A preparation device and technology for glass fiber reinforced plastic, applied in chemical instruments and methods, glass/slag layered products, flat products, etc., can solve the problems of poor surface quality, unsightly appearance, and increased gel coat of glass fiber reinforced plastic, and achieve surface gloss and mechanical properties Significant performance, improved surface gloss and mechanical properties, and the effect of solving quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

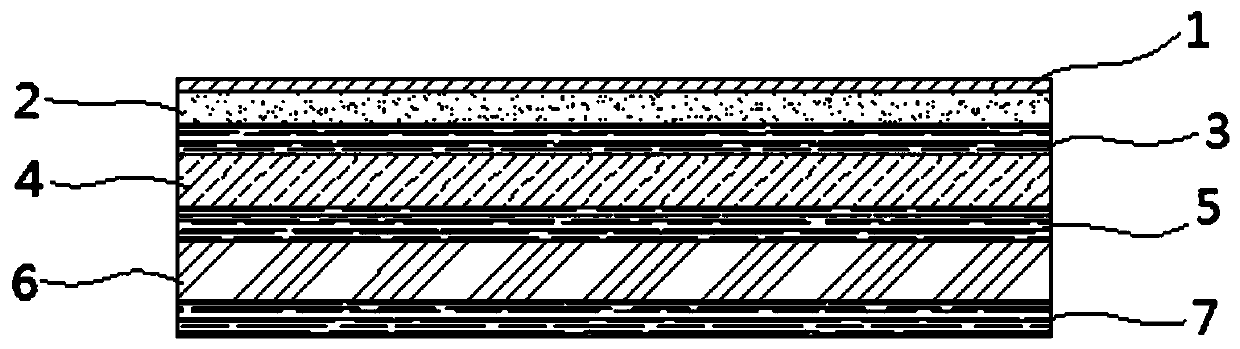

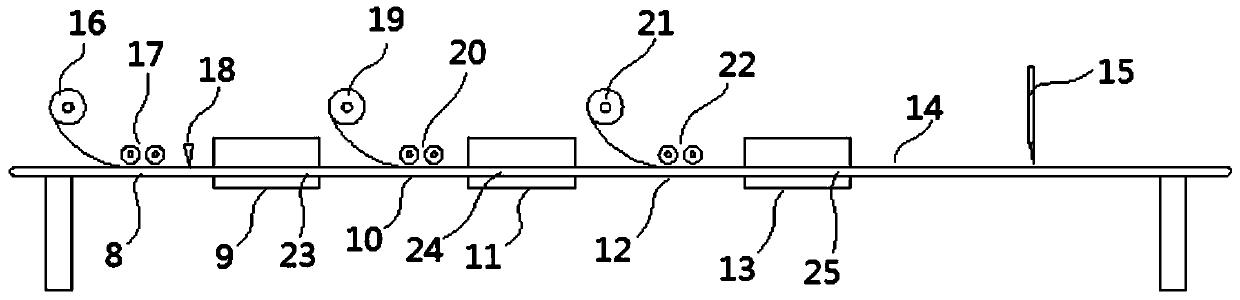

[0037] A method for preparing a mirror-finished glass steel plate, comprising the following steps connected in sequence:

[0038] 1) Unwind the PET film with a thickness of 25 μm on the first conveyor belt, apply a zero-shrink gel coat on the PET film with a gel coat applicator, and use a scraper to control the thickness of the zero-shrink gel coat to 0.15 mm;

[0039] 2) The material obtained in step 1) enters the first curing chamber for curing, the curing temperature is 25°C, and the curing time is 18 minutes;

[0040] 3) The material obtained in step 2) flows out onto the second conveyor belt, and merges with the glass fiber surface mat unrolled by the glass fiber surface mat unwinding device, and then applies unsaturated resin on the surface of the glass fiber surface mat by the first sizing roller , part of the unsaturated resin will penetrate the gel coat layer at the bottom of the glass fiber surface mat, and the weight of the glass fiber surface mat is 60g / m 2 , the ...

Embodiment 2

[0052] It is basically the same as Example 1, except that the unsaturated resin used in step 3) and step 5) is unsaturated resin 196, and the tensile strength of the mirror glass steel plate is 252 MPa.

Embodiment 3

[0054] Basically the same as Example 1, the difference is: in step 2), the curing temperature is 35°C, and the curing time is 18min; in step 4), the curing temperature is 60°C, and the curing time is 3min; in step 6), the curing The temperature is 60°C, the curing time is 3min, and the tensile strength of the mirror glass steel plate is 190MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com