Flexible conductive carbon/metal composite nanofiber membrane, preparation method and application thereof, and lithium-sulfur battery

A nanofiber membrane and metal composite technology, applied in lithium batteries, non-aqueous electrolyte batteries, nanotechnology, etc., can solve the problems of capacity fading, difficult to reach, slow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method for the flexible conductive carbon / metal composite nanofiber membrane described in the above technical solution, comprising the following steps:

[0041] Mix high molecular polymers, metal organic precursors and solvents to obtain spinning solutions, the high molecular polymers are polyacrylonitrile or polyvinylpyrrolidone, and the metal organic precursors include n-butyl titanate, n-zirconate Butyl ester or niobium alcohol;

[0042] Electrospinning the spinning solution to obtain fibers;

[0043] The fibers are carbonized to obtain the flexible conductive carbon / metal composite nanofiber membrane.

[0044] In the present invention, a high molecular polymer, a metal organic precursor and a solvent are mixed to obtain a spinning solution, the high molecular polymer is polyacrylonitrile or polyvinylpyrrolidone, and the metal organic precursor includes n-butyl titanate, zirconium n-Butyl Acetate or Niobium Alcohol....

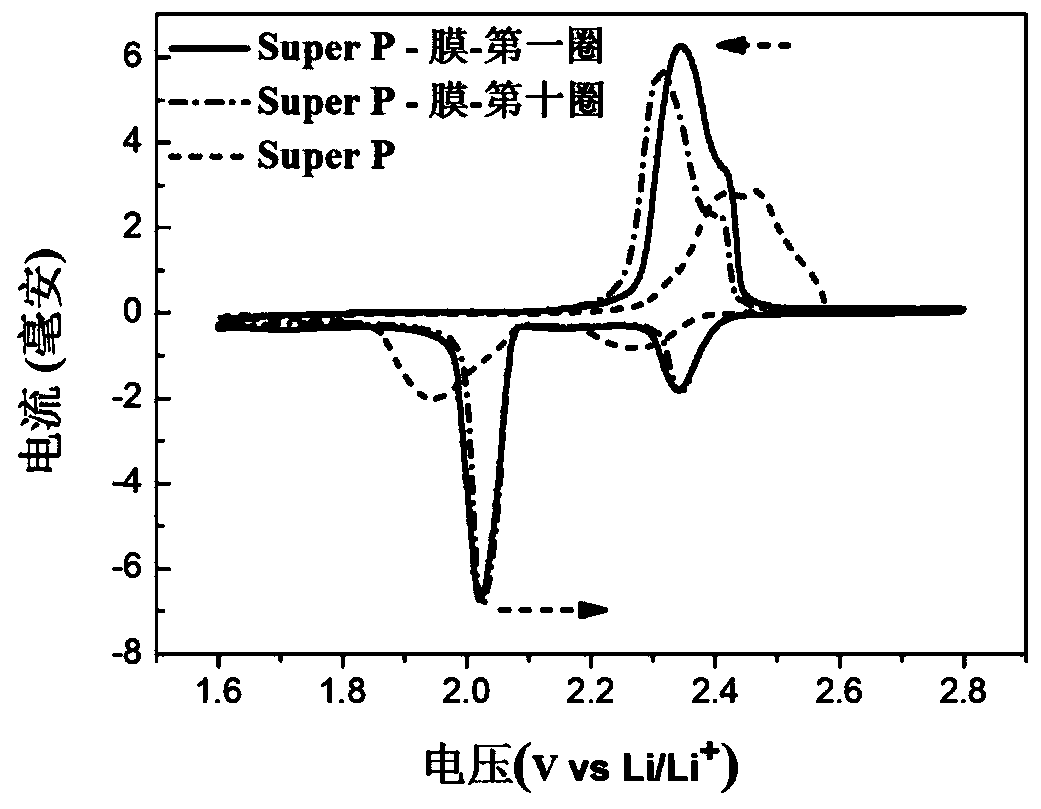

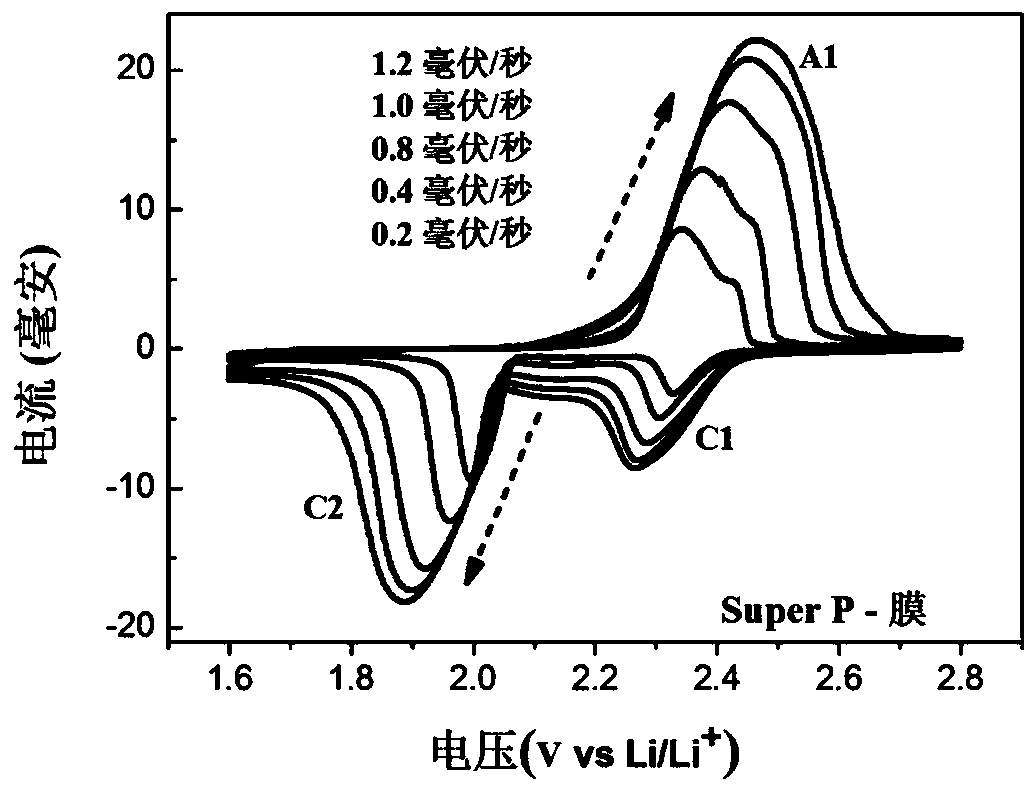

Embodiment 1

[0059] Weigh 4mL of n-butyl titanate, 10mL of N,N-dimethylformamide, and 800mg of polyacrylonitrile, and stir in a 50mL beaker for 12 hours at the same time, until the solution is completely dissolved. Under the condition of -3KV, spin for 4 hours, then carbonize the spun fiber for 1 hour under the condition of high temperature 1000°C and high-purity nitrogen, and finally obtain the carbonized product containing titanium (Ti) nanoparticles. Flexible conductive carbon / metal Composite nanofiber membrane, the fiber membrane has a titanium metal content of 74 atomic percent, an oxygen atomic percent of 14 percent, a nitrogen atomic percent of 4 percent, and the balance being carbon, with a specific surface area of 149.8 m 2 / g, the average pore diameter is 3.18nm. The nanofibrous membrane was then cut into circles of equal size (12 mm in diameter) to serve as membrane reactors for lithium-sulfur batteries.

[0060] Choose 1M LiTFSI and 1% LiNO dissolved in DOL and DME (volume r...

Embodiment 2

[0071] Weigh 4mL of n-butyl titanate, 10mL of N,N-dimethylformamide, and 800mg of polyacrylonitrile, and stir in a 50mL beaker for 12 hours at the same time, until the solution is completely dissolved. Under the condition of -3KV, spin for 4 hours, then carbonize the spun fiber for 2 hours under the condition of high temperature 1000°C and high-purity nitrogen, and finally obtain the carbonized product containing titanium (Ti) nanoparticles. Flexible conductive carbon / metal Composite nanofiber membrane, the fiber membrane has a titanium metal content of 74 atomic percent, an oxygen atomic percent of 14 percent, a nitrogen atomic percent of 4 percent, and the balance being carbon, with a specific surface area of 149.8 m 2 / g, the average pore diameter is 3.18nm. The nanofibrous membrane was then cut into circles of equal size (12 mm in diameter) to serve as membrane reactors for lithium-sulfur batteries.

[0072] Choose 1M LiTFSI and 1% LiNO dissolved in DOL and DME (volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com