Preparation method of gel polymer coating diaphragm and diaphragm

A gel polymer and coating technology, applied in structural parts, electrical components, battery pack components, etc., can solve the problems of difficult thickness control, strong adhesion between the coating separator and the pole piece, and unfavorable electrolyte injection. , to achieve good thickness consistency, improve cycle performance and rate performance, and facilitate injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, a 20 μm polypropylene microporous membrane purchased from Shenzhen Zhongxing New Material Technology Co., Ltd. was used as the base membrane, and polyvinylidene fluoride-hexafluoropropylene gel polymer was used to coat the slurry, and dot coating The way to prepare the gel polymer coating diaphragm of this example, the specific preparation method is as follows:

[0036] (1) pulping

[0037] Add 5.0kg of polyvinylidene fluoride-hexafluoropropylene powder with an average particle size of 200nm into 37kg of acetone solution, stir and heat to 50°C, dissolve for 6h, then add 8kg of the mixed solution, stir for 0.5h, and cool to room temperature to obtain polyvinylidene fluoride-hexafluoropropylene powder. A solution of vinylidene fluoride-hexafluoropropylene in acetone, that is, a gel polymer coating slurry of polyvinylidene fluoride-hexafluoropropylene. Wherein, the mixed solution is a 1:1 solution of dimethyl carbonate and ethanol. The gel polymer coatin...

Embodiment 2

[0041] In this example, the same base film as in Example 1 is used, and the gel polymer coating slurry of polyvinylidene fluoride-hexafluoropropylene is also used, and the method of dot coating is used to prepare the gel polymer coating diaphragm of this example , The difference is that the solid content of the gel polymer coating slurry in this example is different.

[0042] The specific preparation method of the gel polymer coating diaphragm of this example is as follows:

[0043] (1) pulping

[0044] Add 6.0kg of polyvinylidene fluoride-hexafluoropropylene powder with an average particle size of 200nm into 37kg of acetone solution, stir and heat to 50°C, dissolve for 6 hours, then add 7kg of a 1:1 mixture of dimethyl carbonate and ethanol, and stir After 0.5 h, cool to room temperature to obtain polyvinylidene fluoride-hexafluoropropylene acetone solution, which is the gel polymer coating slurry of this example. The gel polymer coating slurry of this example had a solids ...

Embodiment 3

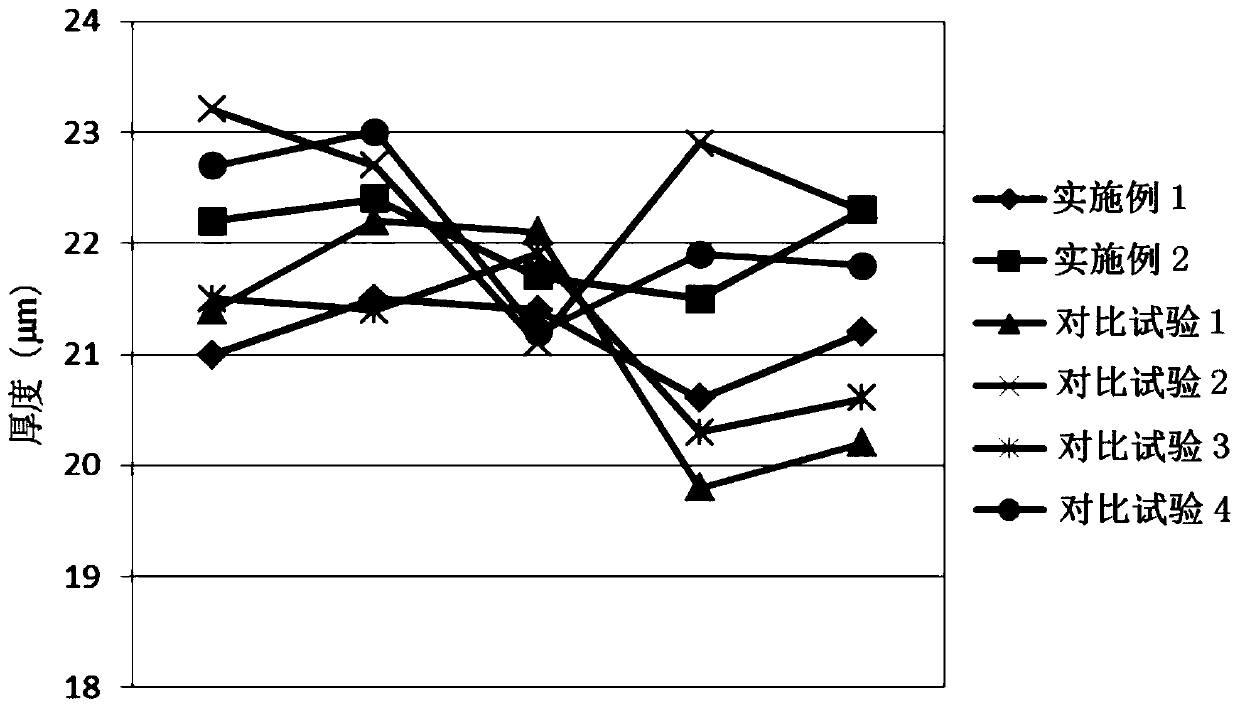

[0061] In this example, on the basis of the above tests and comparative analysis, the solid content of the gel polymer coating slurry was further tested, and the following solid content gel polymer coating slurry was specifically prepared for testing different The effect of solids content on the thickness consistency of gel polymer coated separators is as follows:

[0062] Test 1:

[0063] Add 0.5kg of polyvinylidene fluoride-hexafluoropropylene powder with an average particle size of 200nm into 40kg of acetone solution, stir and heat to 50°C, dissolve for 6h, then add 9.5kg of a 1:1 mixture of dimethyl carbonate and ethanol, Stir for 0.5 h and cool to room temperature to obtain a gel polymer coating slurry with a solid content of 1 wt%.

[0064] Test 2:

[0065] On the basis of Test 1, the amount of polyvinylidene fluoride-hexafluoropropylene powder was adjusted to 1.5 kg, the amount of acetone solution to 38.5 kg, and the mixed solution to 10 kg to obtain a gel polymer coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com