Special rotary drum for small-specification neodymium-iron-boron magnetic steel barrel plating

A NdFeB, small-sized technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of the decrease of the bonding force between the substrate and the coating, the increase of the magnetic attenuation rate of the product, and the decrease of the protection of the coating, so as to reduce the probability of sticking, reduce the Effect of magnetic decay rate and cutting time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

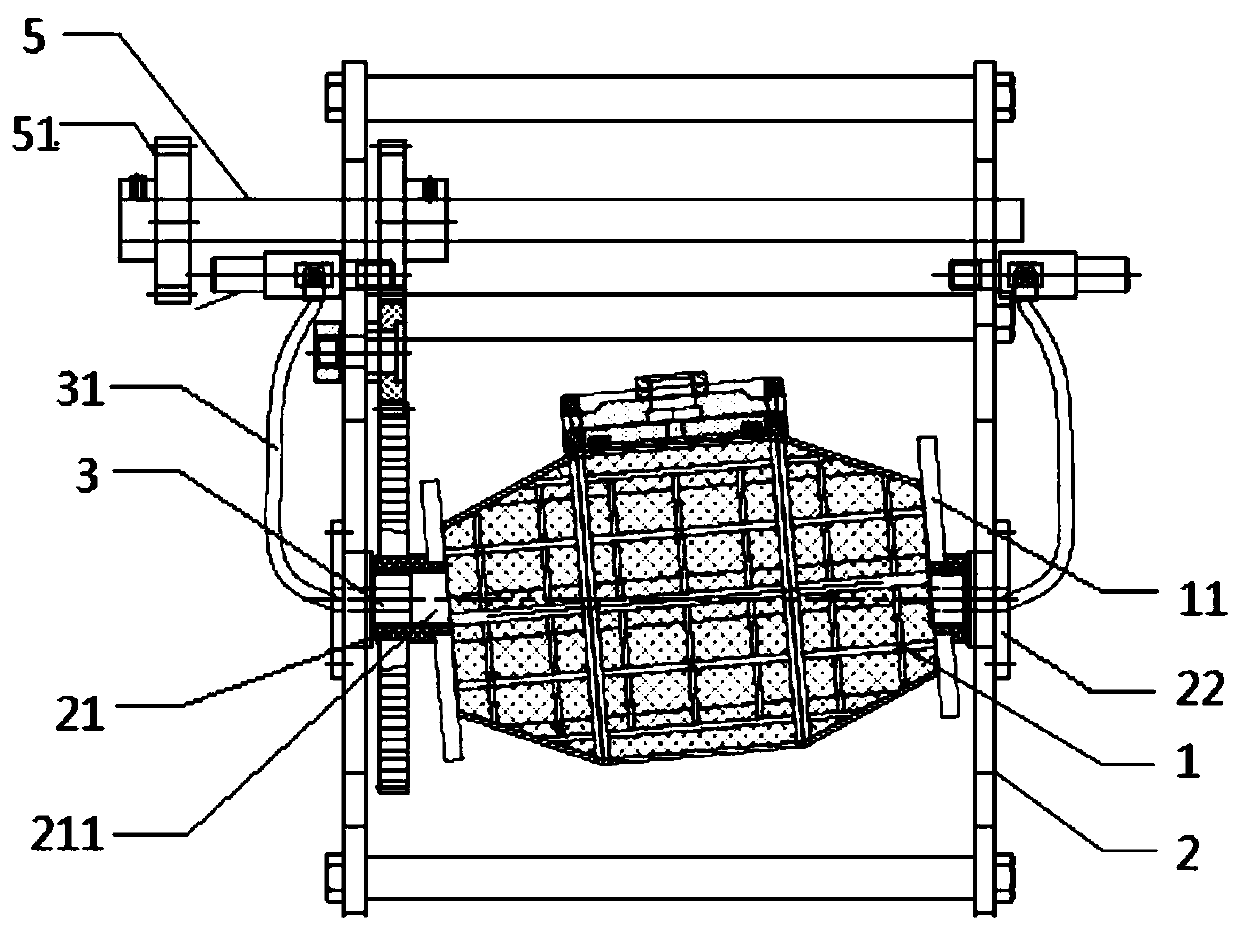

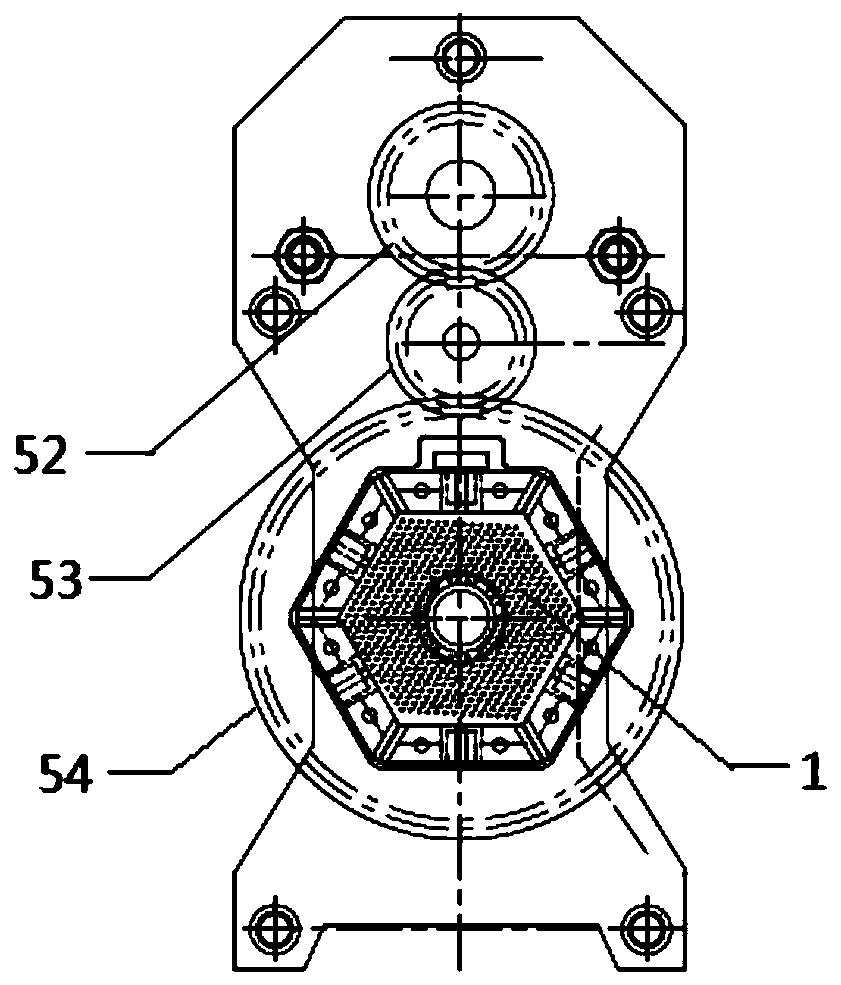

[0033] like figure 1 , figure 2In the shown embodiment 1, a special cylinder for barrel plating of small-sized NdFeB magnetic steel includes a cylinder body 1 , a bracket 2 and a transmission mechanism 5 . The cylinder body 1 is hollow olive-shaped as a whole, with small left and right ends and a large middle part. The cross section of the cylinder body 1 is a regular hexagon. End caps 11 are provided at both ends, and the end caps 11 on both sides are fixedly connected with the main shaft 21 respectively. The main shaft 21 is set horizontally. The shafts intersect at the center of the cylinder body 1. An assembly hole is eccentrically arranged on the end cover 11. The end cover 11 is interference fit with one end of the main shaft 21 through the assembly hole. A transmission mechanism 5 is provided on the outside of the left main shaft 21. The transmission mechanism 5 includes sequentially engaged The fourth gear 54 , the third gear 53 , the second gear 52 , the fourth gea...

Embodiment 2

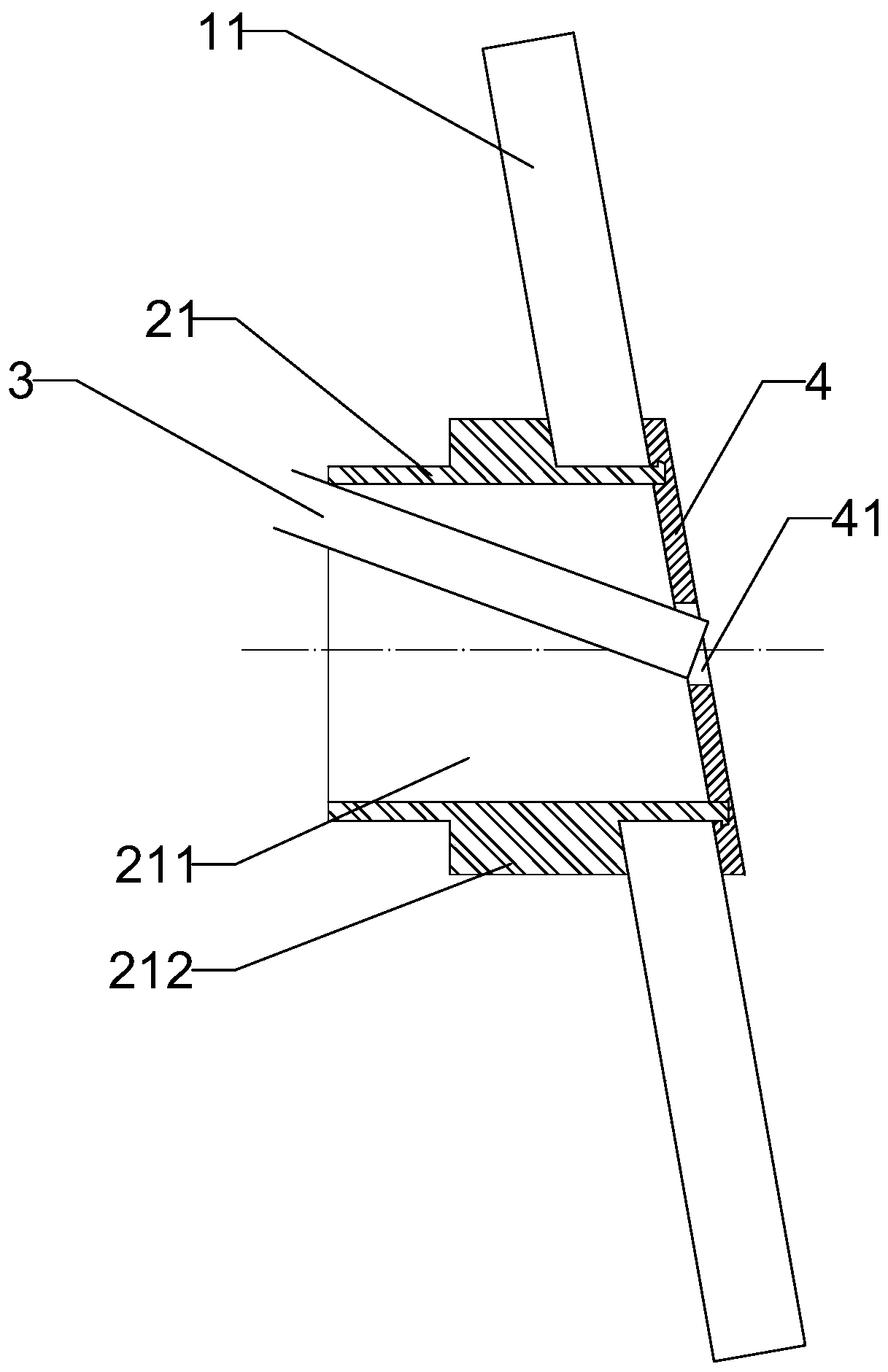

[0036] like figure 2 , image 3 In the shown embodiment 2, a special roller for barrel plating of small-sized NdFeB magnetic steel includes a cylinder body 1 , a bracket 2 and a transmission mechanism 5 . The cylinder body 1 is hollow olive-shaped as a whole, with small left and right ends and a large middle part. The cross section of the cylinder body 1 is a regular hexagon. End caps 11 are provided at both ends, and the end caps 11 on both sides are fixedly connected with the main shaft 21 respectively. The main shaft 21 is set horizontally. The shafts intersect at the center of the cylinder body 1, and an assembly hole is eccentrically arranged on the end cover 11, and the end cover 11 is interference-fitted with one end of the main shaft 21 through the assembly hole. like image 3 As shown, the main shaft 21 is provided with a cavity 211, the cavity 211 runs through the left and right ends of the main shaft 21, the middle part of the main shaft 21 is provided with a fi...

Embodiment example

[0039] Nickel-plated square magnet D7.15*D3.8*0.93, 7.5*1.38 / 3.5*1.1, 3.18*1.7*1.45, 5.88*1.0*0.85 and other small-sized NdFeB magnets in the field of micro motors, after electroplating The thickness of the coating is consistent, and the magnetic decay rate of the magnetic steel is reduced to less than 5%, which meets the needs of users. The neutral salt spray test of the coating is more than 48 hours, and the consistency of the coating is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com