Online adjustment monitoring system for line pressure of rolling machine

A monitoring system and rolling machine technology, applied in rolling force/gap control, metal rolling, etc., can solve problems such as large fluctuations in thickness and range, inability to grasp line pressure, and inability to guarantee battery consistency, etc., to achieve Small range difference, constant line pressure and good thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

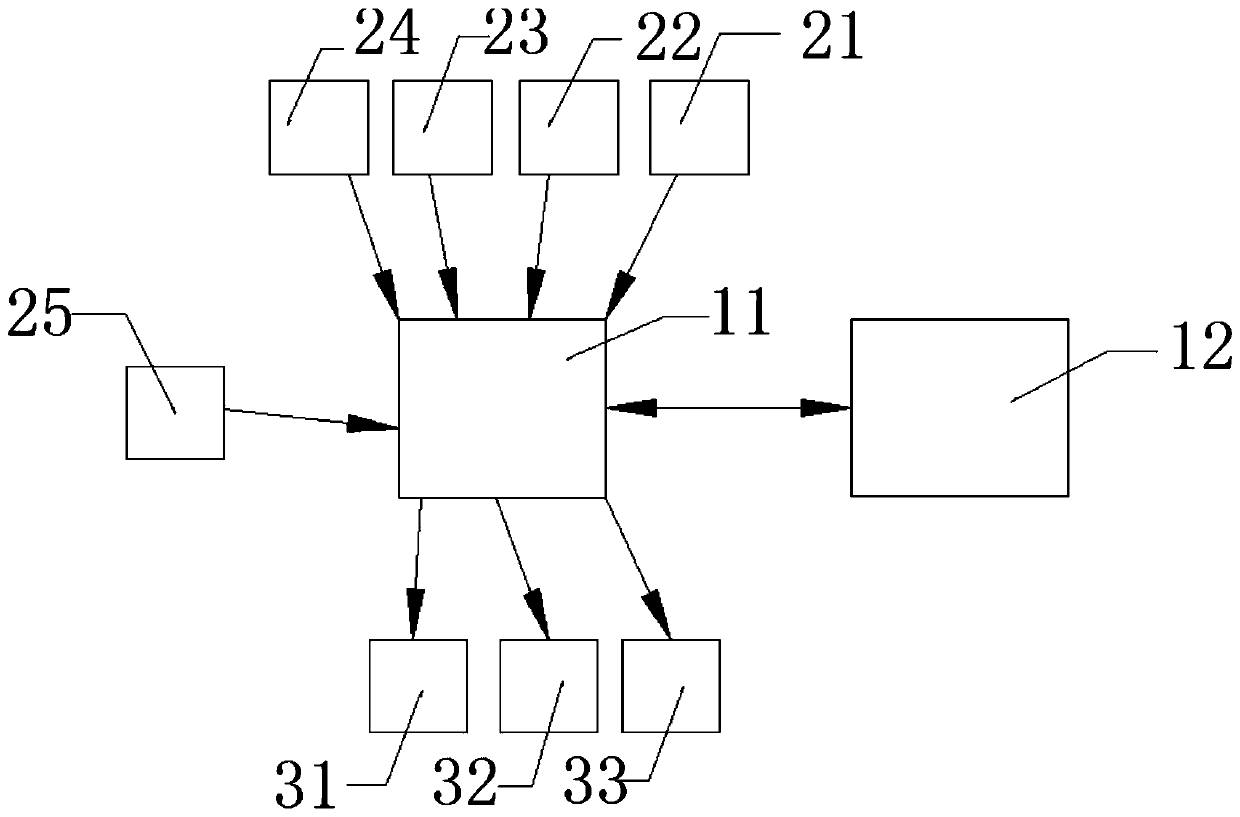

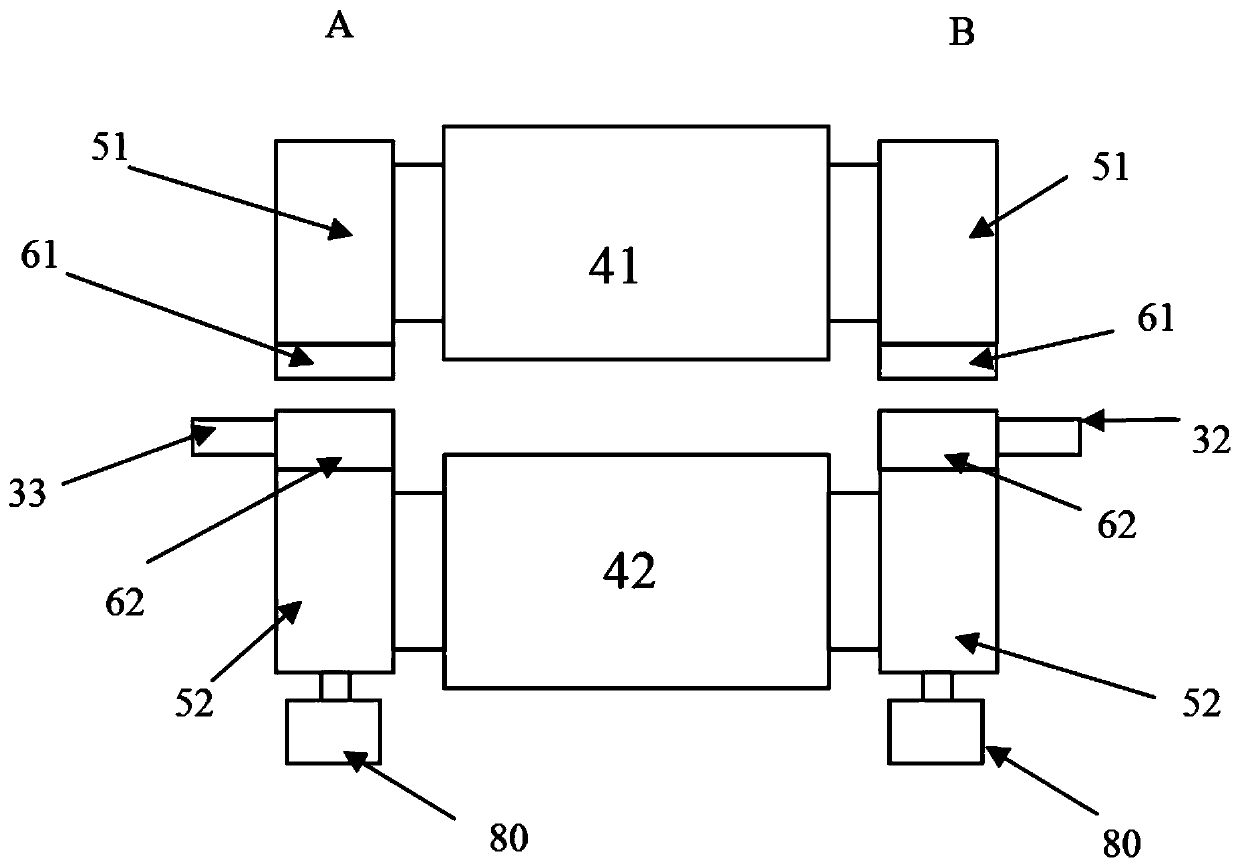

[0052] see figure 1 , figure 2 , the present invention provides an online adjustment and monitoring system for the line pressure of a roller compactor. The left and right sides of the roller compactor are the driving side A and the operating side B respectively;

[0053] The hydraulic station of the rolling machine includes two sets of oil circuits on the left and right sides, which are the driving side hydraulic oil circuit and the operating side hydraulic oil circuit;

[0054] The roller compactor comprises an upper roller 41 and a lower roller 42 distributed up and down at intervals;

[0055] The left and right ends of the upper roller 41 are respectively connected with an upper bearing seat 51;

[0056] The bottom of each upper beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com