Serial feature tracking for endpoint detection

A sequence and end-point technology, applied in the direction of grinding machine parts, workpiece feed motion control, grinding machine tools, etc., can solve problems such as the inability to meet the growing demand of semiconductor device manufacturing, and achieve improved wafer-to-wafer thickness consistency, Improved end-point control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

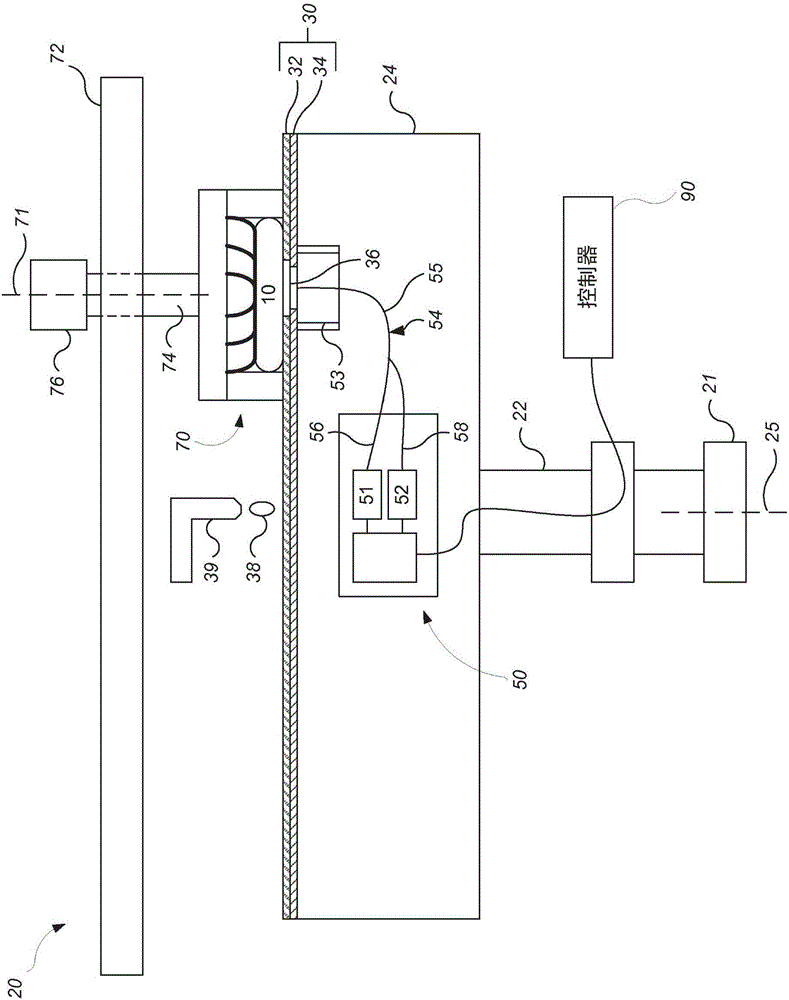

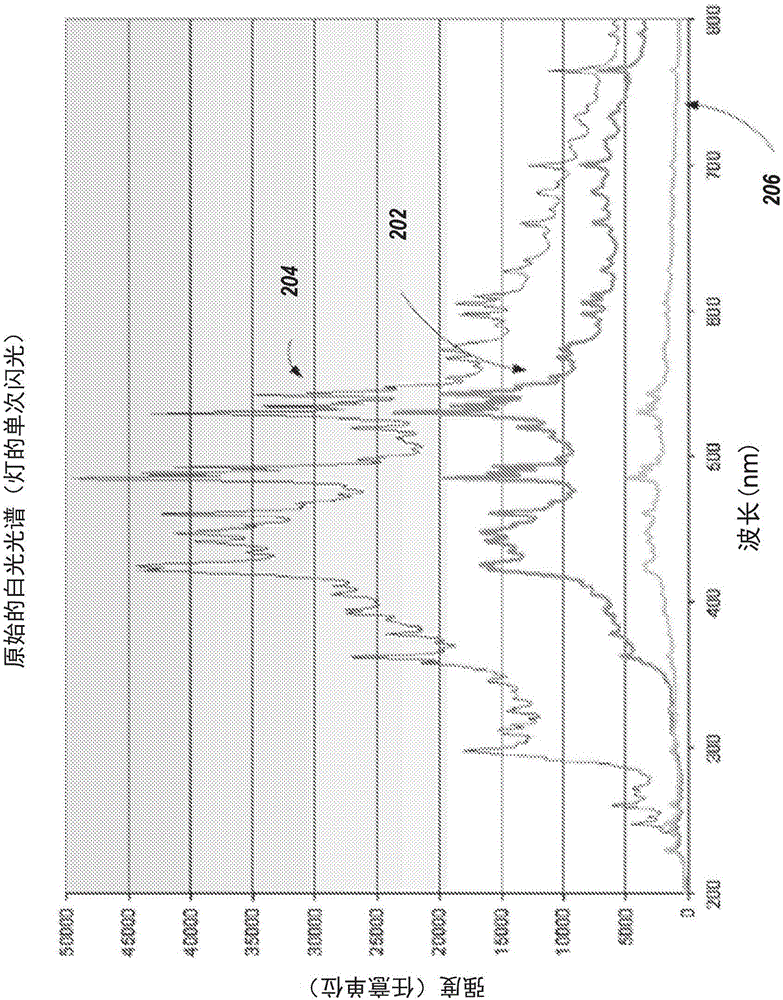

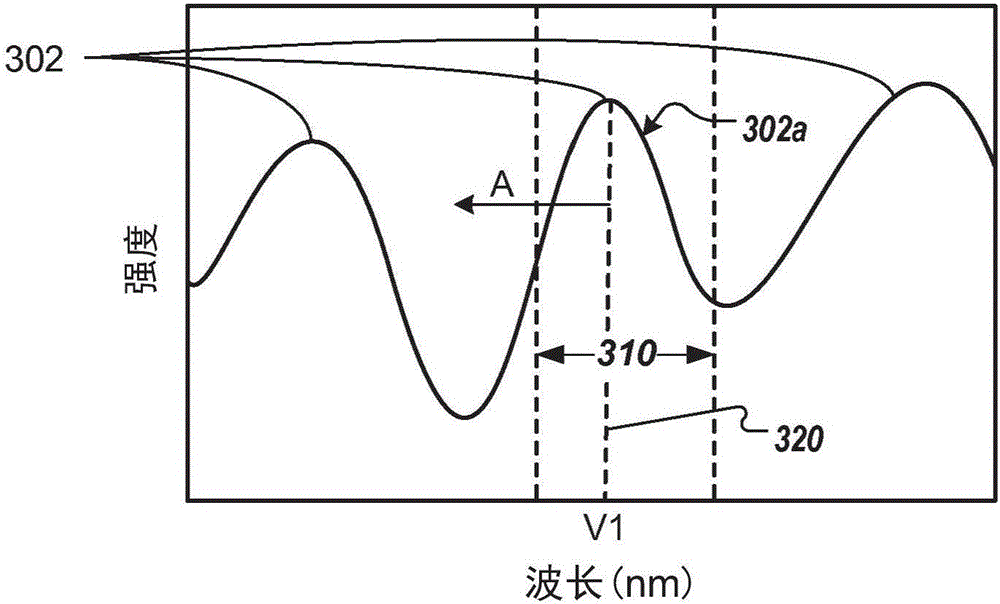

[0017] An optical monitoring technique is used to measure the spectrum of light reflected from a substrate being polished and to track the properties of spectral features (eg, track the position of peaks in the measured spectrum). The modification of the polishing process may be performed based on the value of the property across predetermined boundaries and / or may be changed by a predetermined amount by the property, (e.g., based on crossing a boundary calculated by adding the predetermined amount to the initial value of the property). Modify or trigger the polishing endpoint.

[0018] However, for some layer structures on the substrate, features may shift too much, for example, the wavelength position of a peak may shift completely across the wavelength band being monitored by the spectroscopic system before polishing is complete. A technique used to solve this problem is to serially "stitch" the tracks of multiple features together. For example, once the wavelength of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com