Etching solution composition and etching method for copper-molybdenum film layers

A composition and etching solution technology, applied in the field of display, can solve problems such as unfavorable health of operators, affect the reliability of display panels, high waste liquid treatment cost, etc., and achieve the effects of stable etching process, reduced cost and moderate etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An etching solution composition, comprising the following components by weight percentage: hydrogen peroxide 5.3wt%, N-phenylurea 0.8wt%, tartaric acid 8wt%, isopropanolamine 6.5wt%, diammonium hydrogen phosphate 0.4 wt %, deionized water 79 wt %, the pH of the etching solution composition is 4.9.

Embodiment 2

[0041] An etching solution composition, comprising the following components by weight percentage: hydrogen peroxide 8.6wt%, N,N'-diphenylurea 0.8wt%, benzoic acid 5.5wt%, triisopropanolamine 5wt% %, ammonium phosphate 0.4 wt %, phosphoric acid 1.2 wt %, deionized water 78.1 wt %, and the pH of the etching solution composition was 4.9.

[0042] In order to verify the etching effect of the etching solution composition provided by the above-mentioned embodiment, the following operations are performed:

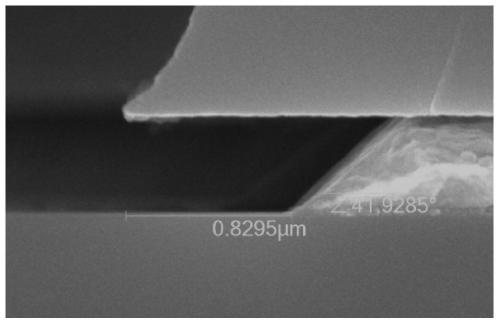

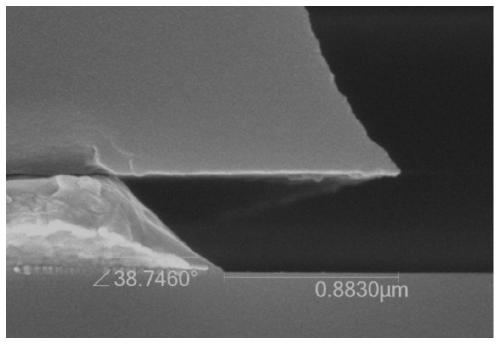

[0043] A layer of copper-molybdenum laminate film is formed on the substrate, specifically, a molybdenum film layer of 300 angstroms is formed on the substrate, and a copper film layer of 7000 angstroms is formed on the molybdenum film layer, and then the copper-molybdenum laminate film is formed on the substrate. A layer of photoresist is coated on the layer, the photoresist is exposed and developed to form a specific shape, and then the etching solution composition provided in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com