A hydrogenation method for producing polyalphaolefin synthetic oil products

A synthetic oil and α-olefin technology, which is applied in the field of hydrogenation to produce high-quality poly-α-olefin synthetic oil products, can solve problems such as incomplete and partial flow hydrogenation, and achieve improved aspect ratio, reduced axial back-mixing, and excellent quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

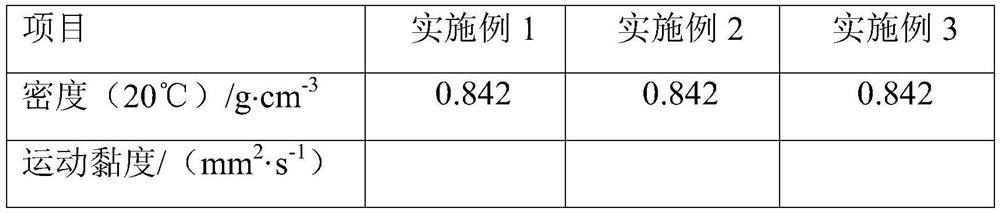

Embodiment 1

[0034] PAO60 cycle oil and feedstock oil according to the mixing ratio of 36:64 by weight, to obtain 100 ℃ moving mixing viscosity of the material 18mm 2 / S, the heated material mixed into the first hydrogenation zone, the hydrogenation reaction was carried out sequentially protecting agent and a hydrogenation catalyst A and purification in the presence of hydrogen, hydrogenation protecting agent charging weight and the ratio of hydrotreating catalyst A 2: 8, which is the reaction effluent directly into the second hydrogenation reaction zone a purification catalyst is contacted with the hydrogenation reaction, after which the reaction effluent liquid separation, the resulting liquid stream is fractionated to give light materials and heavy material, the material as a light cycle oil recycled to the feed tank, said heavy material is a purified poly-α-olefin synthetic oil. The reaction conditions are shown in Table 2, the lightweight nature of the materials shown in Table, the produ...

Embodiment 2

[0036] PAO60 cycle oil and feedstock oil according to the mixing ratio of 36:64 by weight, to obtain 100 ℃ moving mixing viscosity of the material 18mm 2 / S, the heated material mixed into the first hydrogenation zone, the hydrogenation reaction was carried out sequentially protecting agent and a hydrogenation catalyst A and purification in the presence of hydrogen, hydrogenation protecting agent charging weight and the ratio of hydrotreating catalyst A is 3: 7, which reaction effluent directly into the second hydrogenation zone in contact with the hydrotreating catalyst a hydrogenation reaction was carried out, after which the reaction effluent liquid separation, the resulting liquid stream is fractionated to give light materials and heavy material, the material as a light cycle oil recycled to the feed tank, said heavy material is a purified poly-α-olefin synthetic oil. The reaction conditions are shown in Table 2, the lightweight nature of the materials shown in Table, the prod...

Embodiment 3

[0038] PAO60 cycle oil and feedstock oil according to the mixing ratio of 36:64 by weight, to obtain 100 ℃ moving mixing viscosity of the material 18mm 2 / S, the heated material mixed into the first hydrogenation zone, the hydrogenation reaction was carried out sequentially protecting agent and a hydrogenation catalyst A and purification in the presence of hydrogen, hydrogenation protecting agent charging weight and the ratio of hydrotreating catalyst A 2: 8, which is the reaction effluent directly into the second hydrogenation reaction zone in contact with the hydrotreating catalyst B is reacted, after which the reaction effluent liquid separation, the resulting liquid stream is fractionated to give light materials and heavy material, the material as a light cycle oil recycled to the feed tank, said heavy material is a purified poly-α-olefin synthetic oil. The reaction conditions are shown in Table 2, the lightweight nature of the materials shown in Table, the product properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com