Processing method of low-sugar candied prunus salicina fruits

A processing method and preserved fruit technology are applied in the confectionary industry, confectionery, food preservation, etc., which can solve the problems of long drying time, poor taste and flavor of preserved fruit, and long time of candied fruit, so as to achieve short drying time, good taste, The effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

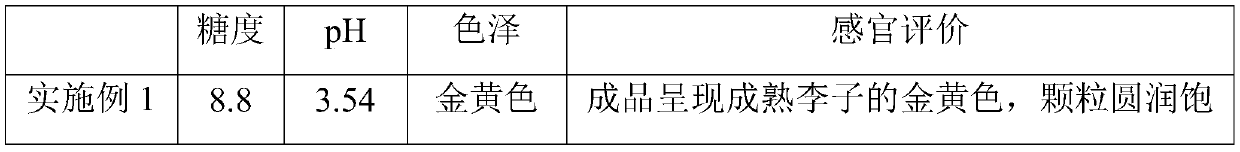

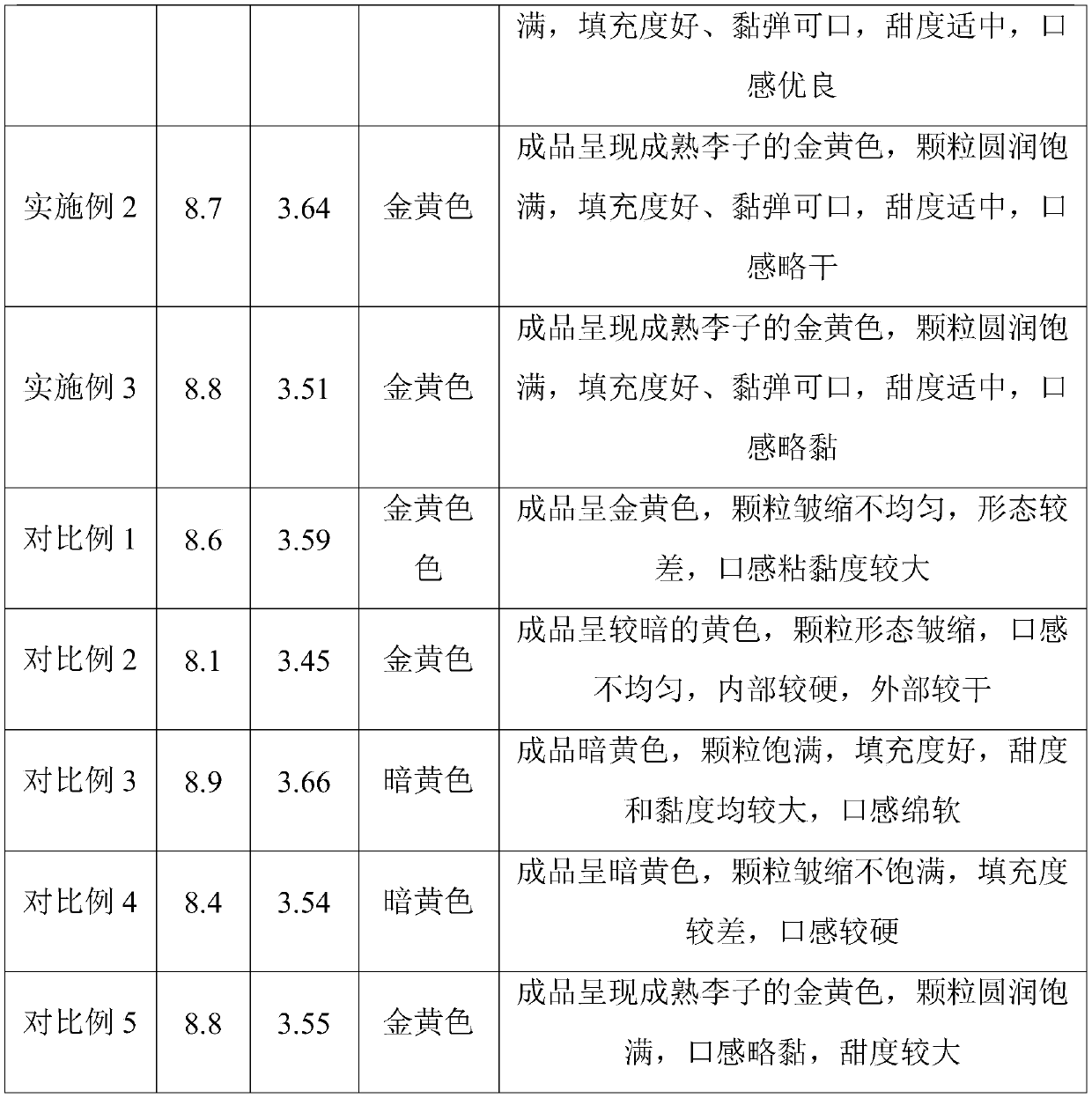

Examples

Embodiment 1

[0026] A kind of low-sugar plum fruit preserved fruit processing method, concrete steps are as follows:

[0027] (1) Cleaning and processing: clean and remove impurities from the fresh plum fruit, remove the surface skin and core of the plum fruit, and cut it along the midline;

[0028] (2) Freezing: the processed plum fruit in step (1) was placed in a freezer at -20°C for 3 hours;

[0029] (3) Initial drying: place the processed plum fruit in step (2) in a vacuum freeze dryer, set the cold trap temperature of vacuum freeze drying to be -40°C, and the vacuum degree to be 10pa, and then dry according to the following drying procedure : Dry at 70°C for 180min, 65°C for 180min, 60°C for 60min, 55°C for 60min, 50°C for 120min, 45°C for 120min;

[0030] (4) Making powdered sugar: mix sucrose, high fructose syrup, xylooligosaccharides and steviol glycosides in a weight ratio of 50:50:10:1 to prepare powdered sugar;

[0031] (5) Making sugar infusion: mix the powdered sugar and pur...

Embodiment 2

[0035] A kind of low-sugar plum fruit preserved fruit processing method, concrete steps are as follows:

[0036] (1) Cleaning and processing: clean and remove impurities from the fresh plum fruit, remove the surface skin and core of the plum fruit, and cut it along the midline;

[0037] (2) Freezing: place the processed plum fruit in step (1) in a freezer at -40°C for 5 hours;

[0038] (3) Initial drying: place the processed plum fruit in step (2) in a vacuum freeze dryer, set the cold trap temperature for vacuum freeze drying at -30°C, and vacuum at 20pa, and dry according to the following drying procedure: 70 Drying at ℃ for 180min, drying at 65℃ for 180min, drying at 60℃ for 60min, drying at 55℃ for 60min, drying at 50℃ for 120min, drying at 45℃ for 120min;

[0039] (4) Making powdered sugar: mix sucrose, fructose syrup, xylooligosaccharides and steviol glycosides in a weight ratio of 60:50:7:1 to prepare powdered sugar;

[0040] (5) Making sugar infusion: mix the powdere...

Embodiment 3

[0044] A kind of low-sugar plum fruit preserved fruit processing method, concrete steps are as follows:

[0045] (1) Cleaning and processing: clean and remove impurities from the fresh plum fruit, remove the surface skin and core of the plum fruit, and cut it along the midline;

[0046] (2) Freezing: place the processed plum fruit in step (1) in a freezer at -40°C for 3 hours;

[0047] (3) Primary drying: place the plum fruit processed in step (2) in a vacuum freeze dryer, set the cold trap temperature of vacuum freeze drying to be-50°C, and vacuum at 10pa, and dry according to the following drying procedures: Dry at 70°C for 180min, 65°C for 180min, 60°C for 60min, 55°C for 60min, 50°C for 120min, 45°C for 120min;

[0048] (4) Making powdered sugar: mix sucrose, high fructose syrup, xylooligosaccharides and steviol glycosides in a weight ratio of 85:85:10:1 to prepare powdered sugar;

[0049] (5) Making sugar infusion: mix the mixed sugar powder prepared in step (4) and purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com