Production process for evaporative pattern centrifugal casting

A technology of centrifugal casting and production technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., and can solve problems such as waste of manpower, difficulty in filling mold dead corners with molding sand, product quality, machining volume, and low work efficiency. Product output, reduce product processing allowance, improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] See how Figure 1-14 Shown is a production process for lost foam centrifugal casting, comprising the following steps:

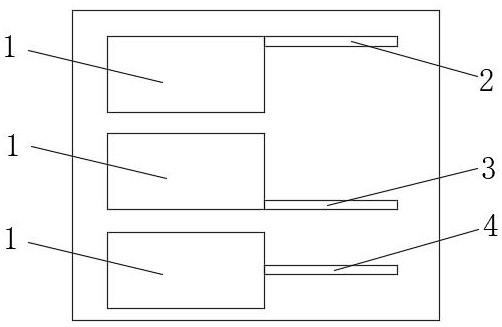

[0069] S1. Positioning of the sprue: including the runner 8, including the top pour 2, the bottom pour 3, and the middle pour 4. The direction of the sprue connection is consistent with the rotation direction of the casting 1, and the casting model is arranged;

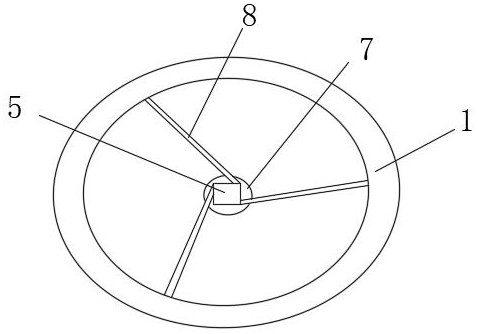

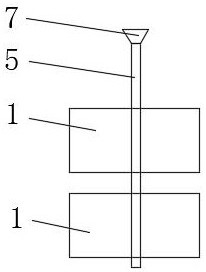

[0070] S1.1. Vertical sprue 5: Connect the sprue at the top, place it vertically, and connect the runner or inner runner at the bottom (when the runner and inner runner are combined). The cross-section shape of the runner is round or square, and the appearance is cylindrical or columnar;

[0071] S1.2. Horizontal sprue 8: connected to the vertical sprue at the top, placed horizontally, and connected to the inner sprue at the bottom. The cross-section shape is square or round. When pouring two or more models at one time, the ends of the bottom surface of the horizontal and vertical runners ca...

Embodiment 2

[0105] See how Figure 7 , a technical solution proposed by the present invention: the difference from Example 1 is: the design of the riser (slag collecting riser or feeding riser) in S2: the riser (slag collecting riser or feeding riser) It is placed close to the center and upper end of the model rotation, so that under the action of centrifugal force, slag and gas move from the casting to the riser (slag collection riser or feeding riser), and the riser (slag collection riser or feeding riser) Riser) is set vertically; the setting position is at the top of the casting.

Embodiment 3

[0107] See how Figure 8 , a technical solution proposed by the present invention: the difference from Example 1 is: the design of the riser (slag collecting riser or feeding riser) in S2: the riser (slag collecting riser or feeding riser) It is placed close to the center and upper end of the model rotation, so that under the action of centrifugal force, slag and gas move from the casting to the riser (slag collection riser or feeding riser), and the riser (slag collection riser or feeding riser) Riser) is set in an inclined direction; the set position is on the upper, middle and lower parts of the side of the casting.

[0108] Figure 8 Middle: vertical (straight) sprue can replace the riser (slag collecting riser or feeding riser)

[0109] In summary: the present invention is flexible in design: it provides sufficient degrees of freedom for the structural design of castings, and highly complex castings can be cast through the combination of foamed plastic molds; it reduces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com