Preparation method of three-dimensional conductive skeleton/metal nitride composite lithium metal negative electrode current collector

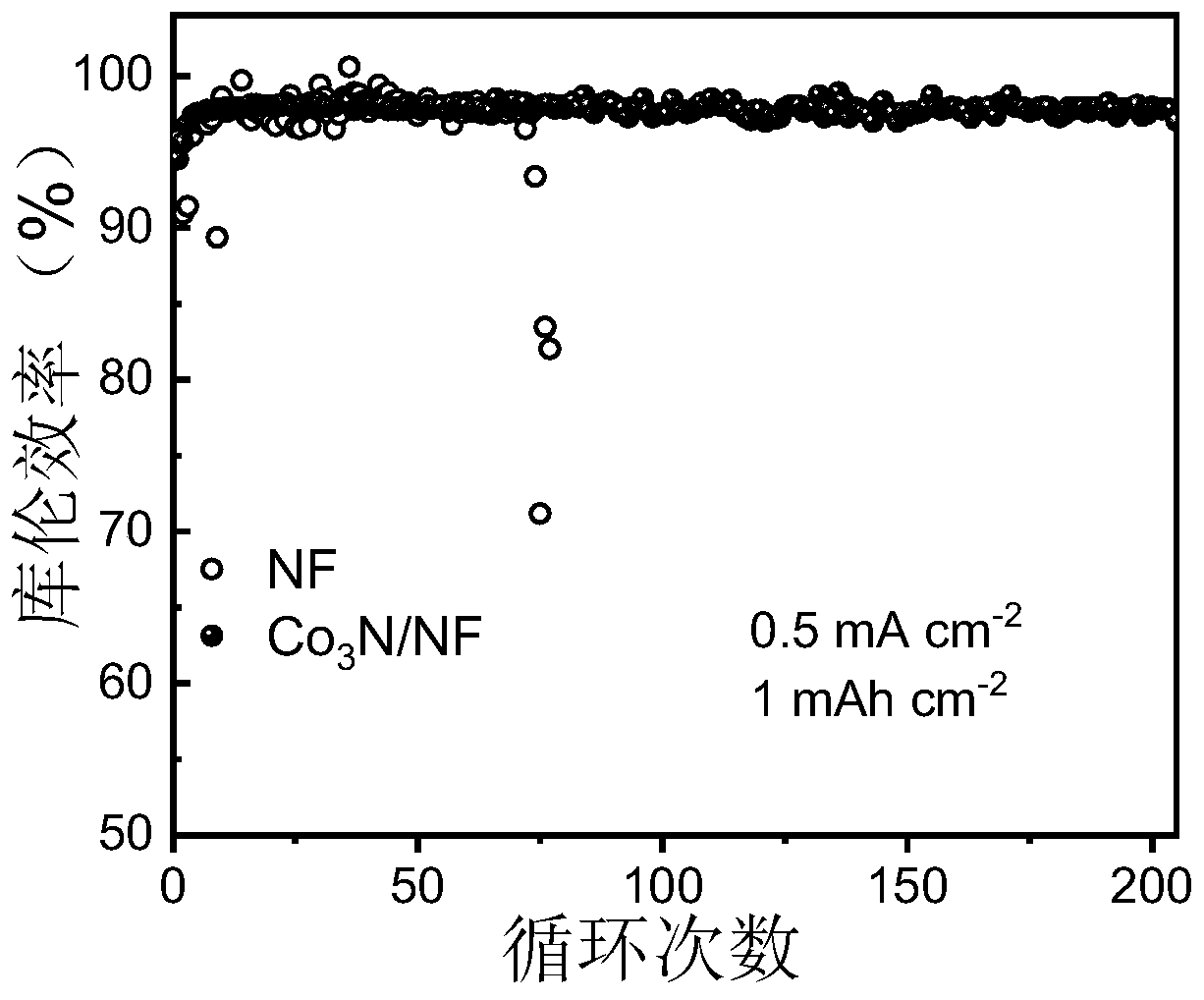

A metal anode and nitride technology, which is applied in the field of preparation of three-dimensional conductive framework/metal nitride composite lithium metal anode current collector, can solve problems such as poor practicability, and achieve the effects of good practicability, long cycle life and growth inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Cut 12mm thick commercial nickel foam into small pieces with a length of 4cm and a width of 2.5cm, ultrasonically clean them with 1.0mol / L dilute hydrochloric acid, absolute ethanol and deionized water to remove surface impurities, and vacuum dry them for later use.

[0030] (2) Cobalt nitrate hexahydrate (CoNO 3 6H 2 O), ammonium fluoride (NH 4 F) and urea (CON 2 h 4 ) were respectively dissolved in deionized water according to the molar concentration of 1.25mol / L, 0.25mol / L, and 0.5mol / L, and stirred for 2h.

[0031] (3) Transfer the mixed solution stirred in step (2) to a polytetrafluoroethylene lining, and immerse the foamed nickel obtained in step (1) into the mixed solution, and react in a hydrothermal kettle at 120° C. for 8 hours, Then cooled to room temperature, washed and dried to obtain a foam nickel (Co(OH)F / NF) composite precursor modified by Co(OH)F nanobrush.

[0032](4) Nitriding the composite precursor obtained in step (3) in an ammonia atmosp...

Embodiment 2

[0034] (1) Cut 12mm thick commercial nickel foam into small pieces with a length of 4cm and a width of 2.5cm, ultrasonically clean them with 1.0mol / L dilute hydrochloric acid, absolute ethanol and deionized water to remove surface impurities, and vacuum dry them for later use.

[0035] (2) Nickel nitrate hexahydrate (NiNO 3 6H 2 O), ammonium fluoride (NH 4 F) and urea (CON 2 h 4 ) were respectively dissolved in deionized water according to the molar concentration ratio of 1.75mol / L, 0.25mol / L, and 0.5mol / L, and stirred for 3h.

[0036] (3) Transfer the mixed solution stirred in step (2) to a polytetrafluoroethylene lining, and immerse the foamed nickel obtained in step (1) into the mixed solution, and react in a hydrothermal kettle at 90° C. for 10 h, Then cooled to room temperature, washed and dried to obtain Ni(OH)F nanobrush-modified foam nickel (Ni(OH)F / NF) composite precursor.

[0037] (4) Nitriding the composite precursor obtained in step (3) in an ammonia atmosphe...

Embodiment 3

[0039] (1) Cut 12mm thick commercial nickel foam into small pieces with a length of 4cm and a width of 2.5cm, ultrasonically clean them with 1.0mol / L dilute hydrochloric acid, absolute ethanol and deionized water to remove surface impurities, and vacuum dry them for later use.

[0040] (2) ferric chloride hexahydrate (FeCl 3 6H 2 O), ammonium fluoride (NH 4 F) and urea (CON 2 h 4 ) were respectively dissolved in deionized water according to the molar concentration ratio of 2.5mol / L, 0.5mol / L, and 1mol / L, and magnetically stirred for 4h.

[0041] (3) Transfer the mixed solution stirred in step (2) to a polytetrafluoroethylene lining, and immerse the foamed nickel obtained in (1) into the mixed solution, react in a hydrothermal kettle at 180°C for 5h, and then Cool to room temperature, wash and dry to obtain Fe(OH)F nanobrush-modified foam nickel (Fe(OH)F / NF) composite precursor.

[0042] (4) Nitriding the composite precursor obtained in step (3) in an ammonia atmosphere, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com