Numerical control NC code virtual and real verification method based on RGB-D camera

A verification method and code technology, applied in image data processing, image enhancement, instruments, etc., can solve the problems of operator's personal safety threat, inability to guarantee consistency, and inability to guarantee the correctness of actual processing, so as to avoid workpiece scrap and tool collision. problems, improve reliability and authenticity, and solve the effect of incomplete machine models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

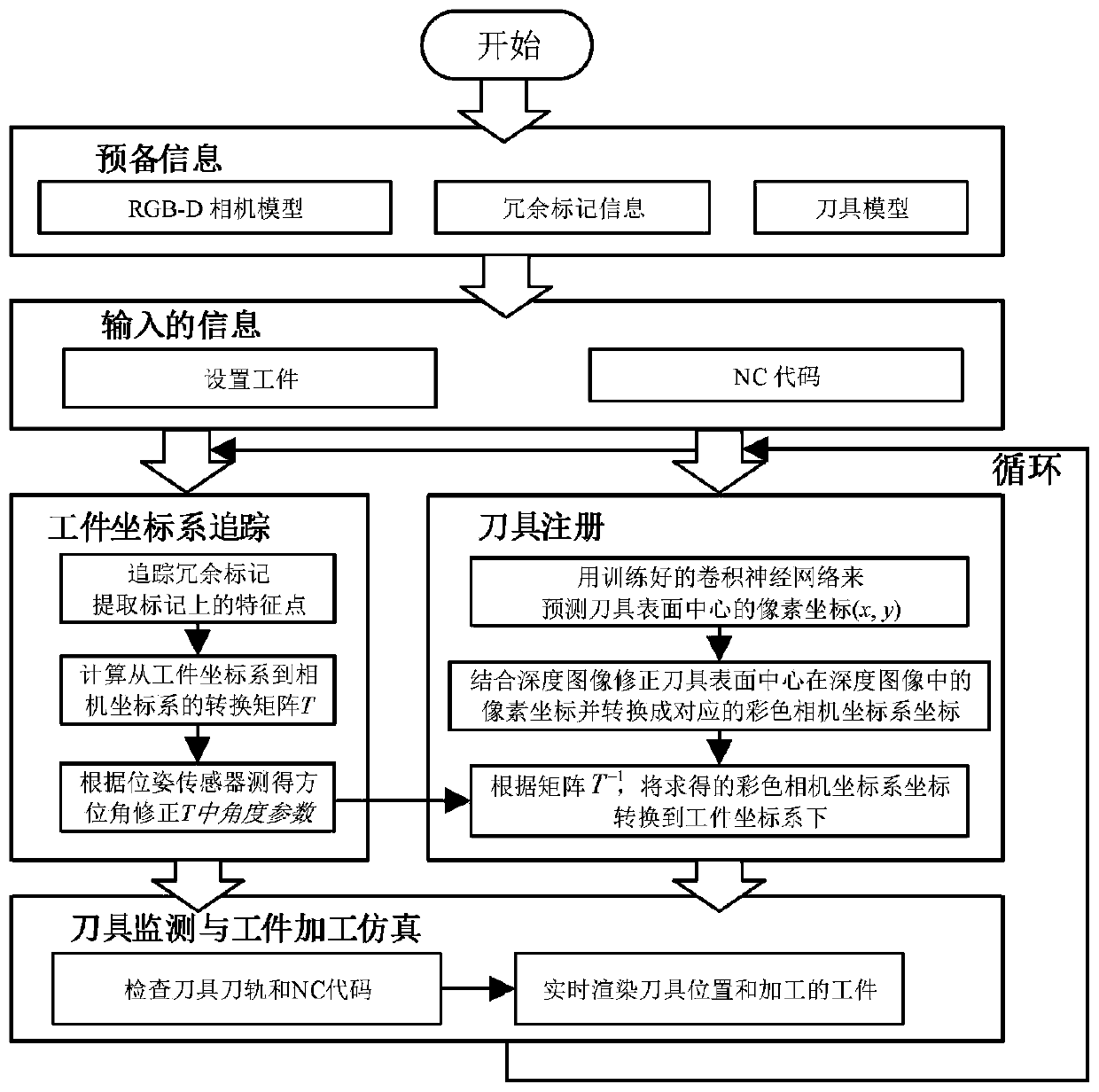

[0038] Such as figure 1 As shown, a kind of machine tool NC code augmented reality processing simulation method based on RGB-D camera involved in the method of the present invention comprises the following steps:

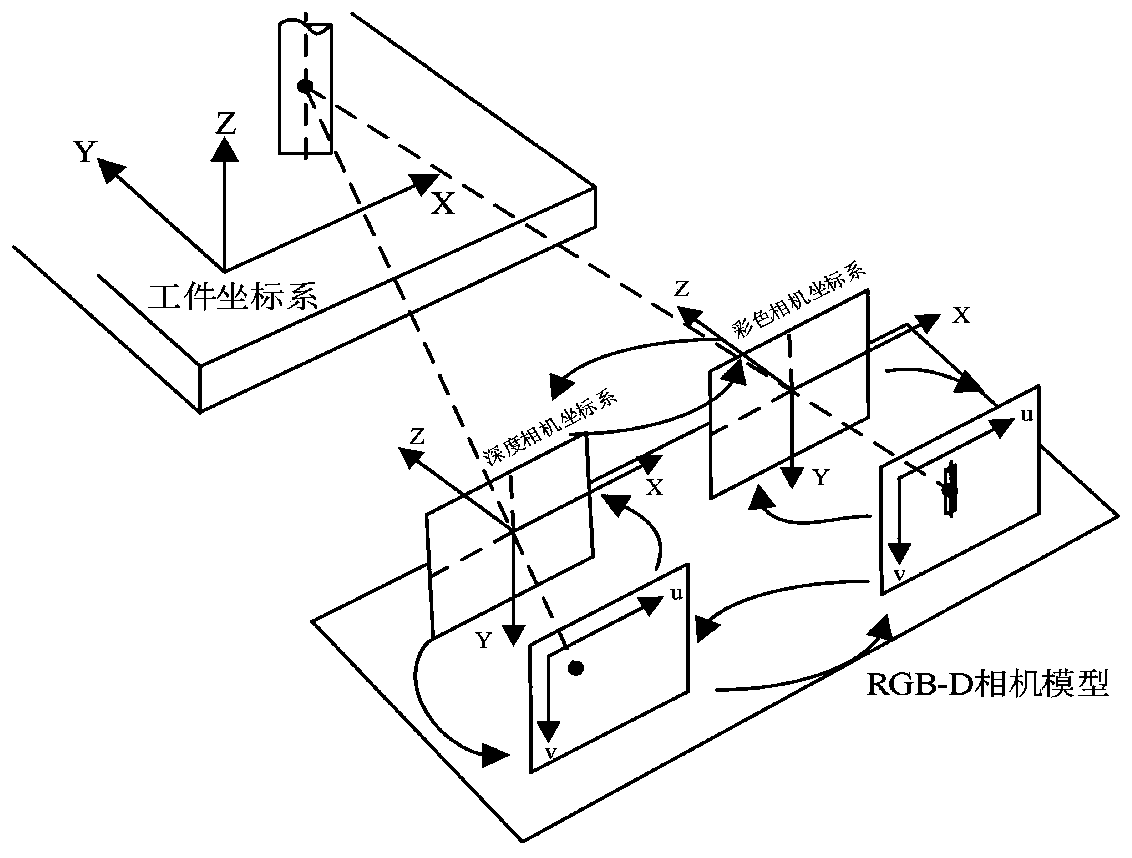

[0039] Step S10: Calibrate the internal parameters of the color camera and the depth camera of the RGB-D camera, and calculate the external parameters between the two cameras, and establish a mapping model from color pixels to depth pixels according to the internal parameters and external parameters. The coordinate systems involved are as follows: figure 2 shown.

[0040] In this embodiment, a mapping model from color pixels to depth pixels is established, specifically based on the pinhole imaging model an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com