Green method for preparing battery grade nickel sulfate from nickel salt

A battery-grade, nickel sulfate technology, applied in the field of hydrometallurgy, can solve the problems of long process flow and high environmental protection pressure, and achieve the effects of easy process, reduced environmental protection burden, and reduced impurity removal process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

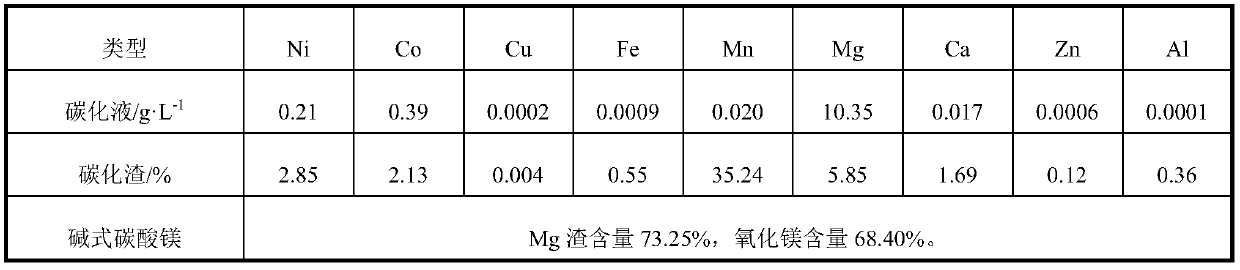

Image

Examples

Embodiment 1

[0026] A kind of green method that nickel salt prepares battery-grade nickel sulfate, concrete steps are as follows:

[0027] 1. Mix 50g of nickel salt and 32g of ammonium salt into the reaction vessel, add 12% ammonia water as the leaching agent according to the liquid-solid ratio of 4:1, control the reaction time to 2.0h, the reaction temperature to 30°C, and the stirring speed to 300rpm The ammonia leaching reaction is carried out under the same conditions, and the solid-liquid separation is carried out after the reaction to obtain a section of ammonia leaching solution.

[0028] 2. One-stage ammonia immersion liquid controls the ammonia distillation time to be 5 hours and the temperature to 90°C. Use 10% dilute sulfuric acid to adjust the concentration of free ammonia in the liquid after ammonia distillation to 24.65g / L and pH to 7.63 to carry out pressurized hydrogen reduction reaction.

[0029] 3. The liquid after ammonia distillation is subjected to pressurized hydrogen...

Embodiment 2

[0034] A kind of green method that nickel salt prepares battery-grade nickel sulfate, concrete steps are as follows:

[0035] 1. Mix 50g of nickel salt and 66g of ammonium salt into the reaction vessel, add 14% ammonia water as the leaching agent according to the liquid-solid ratio of 4:1, control the reaction time to 2.0h, the reaction temperature to 50°C, and the stirring speed to 400rpm The ammonia leaching reaction is carried out under the same conditions, and the solid-liquid separation is carried out after the reaction to obtain a section of ammonia leaching solution.

[0036] 2. One-stage ammonia immersion liquid controls the ammonia distillation time to be 6 hours and the temperature is 95°C, use 40% dilute sulfuric acid to adjust the concentration of free ammonia in the liquid after ammonia distillation to 19.17g / L, and the pH is 7.52 to carry out the pressurized hydrogen reduction process .

[0037] 3. After ammonia distillation, the hydrogen partial pressure of the...

Embodiment 3

[0042] A kind of green method that nickel salt prepares battery-grade nickel sulfate, concrete steps are as follows:

[0043] 1. Mix 50g of nickel salt and 66g of ammonium salt into the reaction vessel, add 14% ammonia water as the leaching agent according to the liquid-solid ratio of 4:1, control the reaction time to 2.0h, the reaction temperature to 50°C, and the stirring speed to 400rpm The ammonia leaching reaction is carried out under the same conditions, and the solid-liquid separation is carried out after the reaction to obtain a section of ammonia leaching solution.

[0044] 2. One-stage ammonia immersion liquid controls the ammonia distillation time to be 5 hours and the temperature is 95°C, use 20% dilute sulfuric acid to adjust the concentration of free ammonia in the liquid after ammonia distillation to 30.43g / L, and the pH is 8.13 to carry out the pressurized hydrogen reduction process .

[0045] 3. After ammonia distillation, the hydrogen partial pressure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com