25-hydroxyvitamin D3 production strain, and screening method and application thereof

A technology for the production of hydroxyvitamins and bacterial strains, which is applied in the field of bioengineering, can solve the problems of long cultivation period and high production cost, and achieve the effects of rapid growth, shortened production period and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

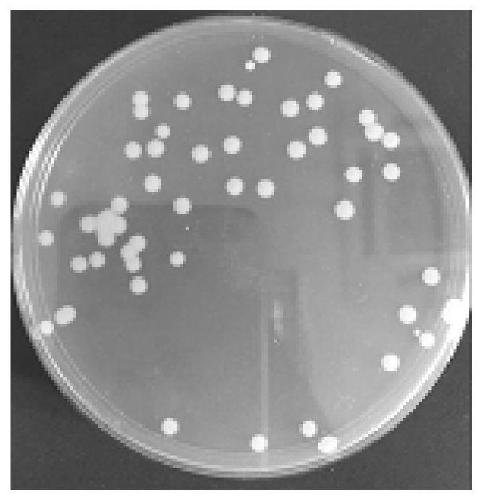

[0028] Example 1 High yield of 25-hydroxyvitamin D 3 Screening of strains

[0029] Take a soil sample from the deep soil layer near the chemical plant, weigh about 1.0 g, and add it to 30 mL of sterile water to prepare a bacterial suspension. Draw 0.5mL of the bacterial suspension and inoculate it into the enrichment medium, and culture it on a constant temperature shaker at 37°C for 3 days. The culture solution was diluted with the mother solution and spread on the separation medium plate, and cultivated at 37°C for 24h. Pick 254 single colonies for transformation experiments, extract the transformation solution and detect 25-hydroxyvitamin D by high performance liquid chromatography 3 concentration. details as follows:

[0030] (1) Pick a single colony and culture it in the seed medium at 37°C for 12 hours to obtain the seed solution;

[0031] (2) The seed solution was inoculated in 50 mL transformation medium and cultivated for 12 hours;

[0032] (3) Take 1mL VD 3 Th...

Embodiment 2

[0035] Example 2 Different VD 3 Dissolving solvent vs. 25OH-VD 3 Yield impact

[0036] Although zju 4-2 can obtain a higher yield (70.4%), VD 3 The added solubility of β-cyclodextrin is low (0.039g / L dissolved in 200g / Lβ-cyclodextrin), which is not conducive to large-scale industrial production.

[0037] In order to improve VD 3 The dispersibility of 10% by volume, under 200rpm constant speed oscillation, VD 3 Five common solvents, ethanol, methanol, ethyl acetate, propylene glycol and ethylene glycol, were evaluated at a concentration of 0.1 mM. As shown in Table 1, the solubility of five solvents to VD3 is much greater than that of β-cyclodextrin. In addition, if Figure 4 As shown, ethanol dissolves VD 3 25OH-VD obtained by transformation 3 The yield (40%) and propylene glycol dissolved VD 3 25OH-VD obtained by transformation 3 The yield (54%) was higher than ethyl acetate (20%), methanol (17%) and ethylene glycol (35%). Therefore, ethanol and propylene glycol ar...

Embodiment 3

[0040] Example 3 VD 3 Propylene Glycol to Ethanol Ratio in Dissolving Solvent vs. 25OH-VD 3 Yield impact

[0041] Dissolving VD due to ethanol and propylene glycol 3 Conversion and synthesis of 25OH-VD 3 The yield is higher, but the two have different solubility to VD3. Further, dissolving VD3 in a mixed solvent of propylene glycol and ethanol is converted into 25OH-VD 3 . The feasibility is evaluated, and the balance between solubility and yield is achieved by adjusting the ratio of the two. Such as Figure 5 As shown, the ratio of propylene glycol to ethanol can obtain higher 25OH-VD between 10:0~5:5 (v / v) 3 Yield and dry cell weight. Especially when the ratio (v / v) of propylene glycol to ethanol was 9:1, the yield was 50.1%, and VD 3 The solubility in the co-solvent mixture was significantly increased to 24.49g / L, at which point the VD3 solubility as well as the 25OH-VD 3 Yield reached the highest, which is the best solvent ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com