High-adhesion room-temperature self-crosslinking acrylic resin, and preparation method and application thereof

An acrylic resin, high-adhesion technology, used in adhesive types, coatings, primers, etc., can solve the problems of poor substrate adhesion, long construction time, and troublesome construction, and achieve strong adhesion and improved adhesion. The effect of joint density and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

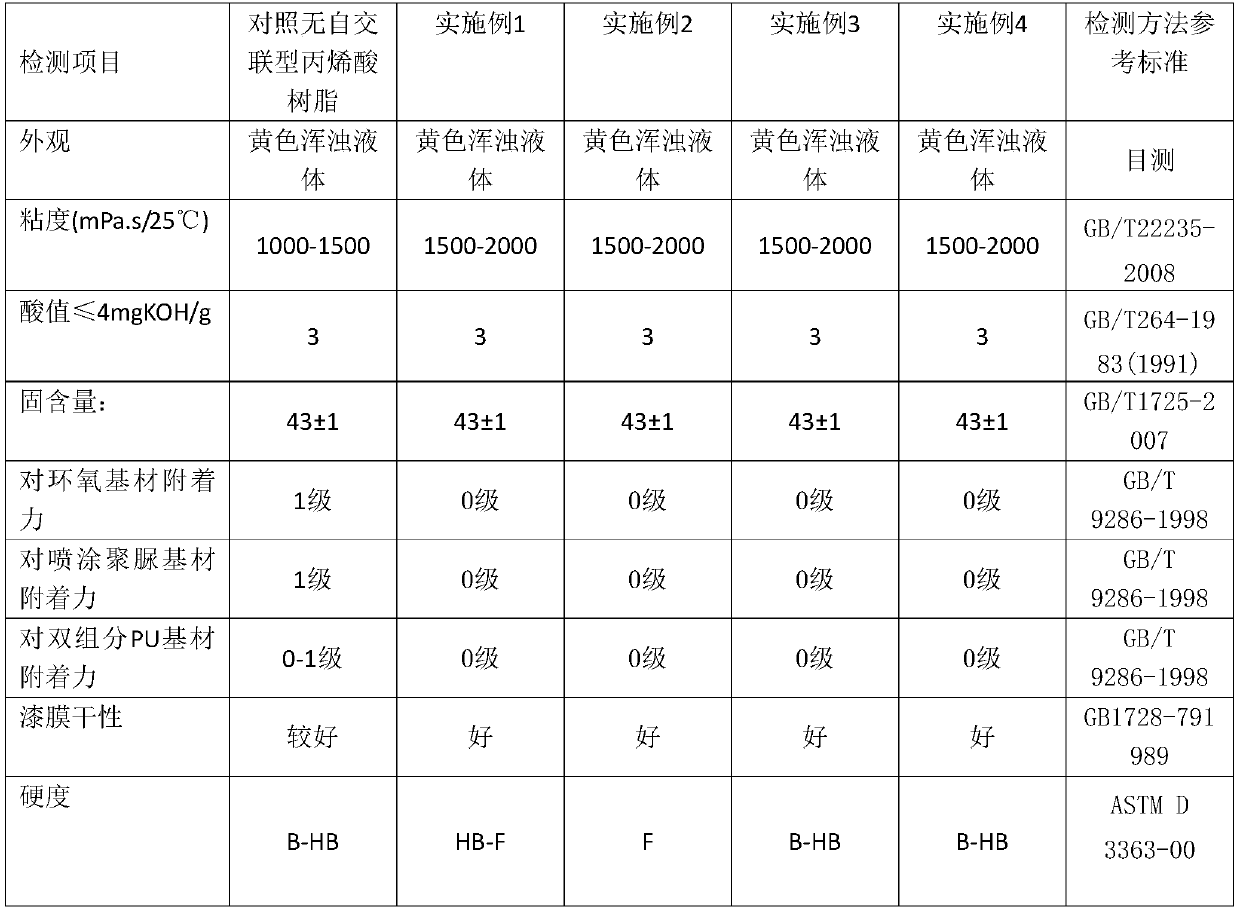

Examples

Embodiment 1

[0026] A preparation method of high adhesion room temperature self-crosslinking type acrylic resin, the specific implementation steps are as follows:

[0027] Mix 25 parts of xylene and 20 parts of propylene glycol methyl ether acetate solvent and heat up to 120°C, put in 3 parts of high-chlorinated polypropylene resin, stir and dissolve, and keep warm for 30 minutes; In the mixed solvent of the resin, and carry out the polymerization reaction, maintain the polymerization reaction temperature at 120 ° C, and drop the reaction time for 3 hours. The mixed monomer is made of the following weight fractions: 19 parts of methyl methacrylate, butyl methacrylate 14.3 parts, 3 parts of butyl acrylate, 0.4 part of acrylic acid, 3 parts of ethyl isocyanate acrylate, 0.2 part of di-tert-butyl peroxide; mix the remaining 12 parts of butyl acetate and 0.1 part of di-tert-butyl peroxide, Add dropwise to the reactor within 30 minutes, raise the temperature and maintain the reaction temperatur...

Embodiment 2

[0029] A preparation method of high adhesion room temperature self-crosslinking type acrylic resin, the specific implementation steps are as follows:

[0030] Heat 35 parts of xylene and 10 parts of butyl acetate solvent to 110°C, put in 2.5 parts of high-chlorinated polypropylene resin, stir and dissolve, and keep warm for 30 minutes; add the mixed monomer dropwise to the mixed solvent dissolved in high-chlorinated polypropylene resin and carry out the polymerization reaction, maintain the polymerization reaction temperature at 130 ° C, and drop the reaction time for 5 hours. The mixed monomers are made of the following weight fractions: 22 parts of methyl methacrylate, 12.3 parts of butyl methacrylate, acrylic acid 3.0 parts of butyl ester, 0.4 part of acrylic acid, 2.5 parts of ethyl isocyanate acrylate, 0.2 part of di-tert-butyl peroxide; mix the remaining 12 parts of xylene and 0.1 part of di-tert-butyl peroxide, and drop them within 30 minutes , heat up and maintain the ...

Embodiment 3

[0032] A preparation method of high adhesion room temperature self-crosslinking type acrylic resin, the specific implementation steps are as follows:

[0033] Heat 45 parts of xylene solvent to 150°C, put in 3.5 parts of high-chlorinated polypropylene resin, stir and dissolve, and keep warm for 40 minutes; drop the mixed monomer into the mixed solvent dissolved in high-chlorinated polypropylene resin, and carry out polymerization Reaction, keep the polymerization reaction temperature at 125°C, dropwise reaction time is 4h, the mixed monomers are made of the following weight fractions: 15 parts of methyl methacrylate, 17.8 parts of butyl methacrylate, 4 parts of butyl acrylate, 0.4 parts of acrylic acid, 2 parts of isocyanate ethyl acrylate, 0.2 parts of di-tert-butyl peroxide; mix the remaining 12 parts of propylene glycol methyl ether acetate and 0.1 parts of di-tert-butyl peroxide, drop them within 30 minutes, and heat up And maintain the reaction temperature at 138°C; maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com