A rapid synthesis of mesoporous nanostate ln 2 o 2 so 4 Preparation method of oxygen storage material

A 2O2SO4, oxygen storage technology, applied in catalyst activation/preparation, separation methods, chemical instruments and methods, etc., can solve the problems of long preparation cycle, complex process, many control points, etc., to achieve short preparation cycle, simple preparation process, The effect of suppressing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

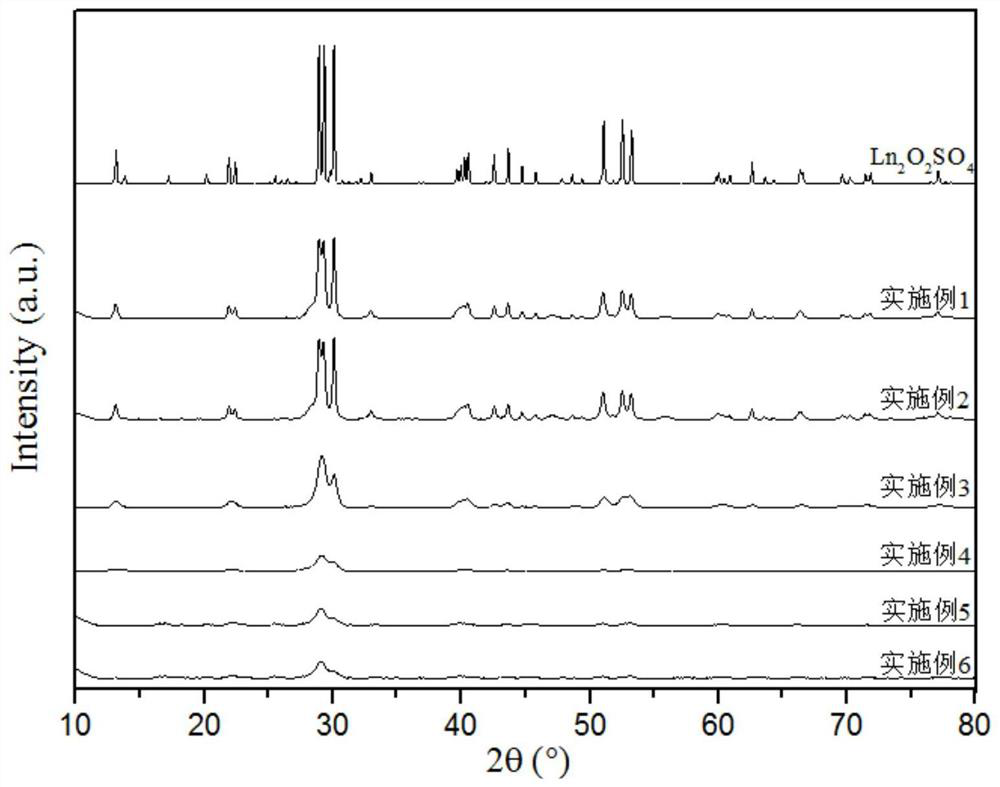

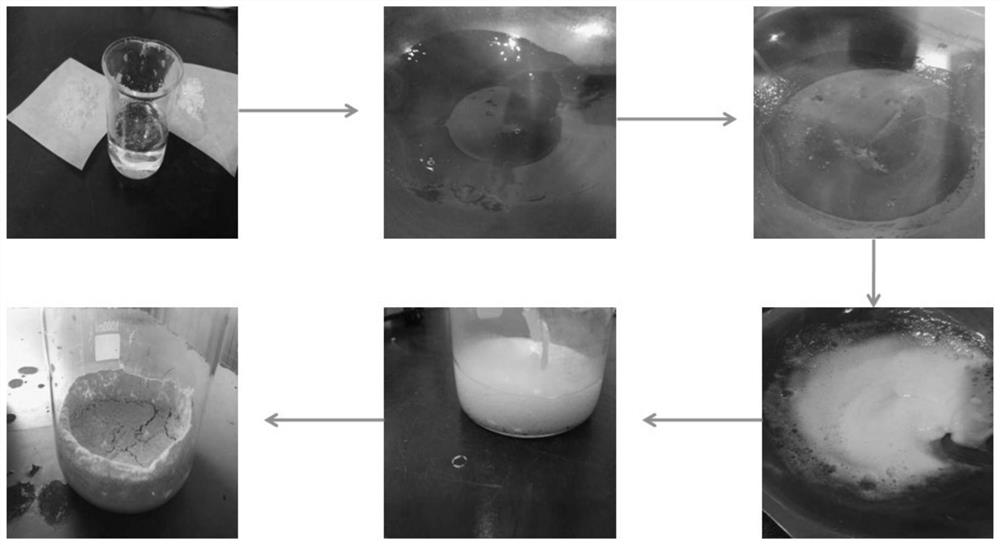

[0019] Weigh 10.67g La (NO 3 ) 3 ·6H 2 O is placed in an agate mortar and smashed and finely ground, add 7.33 g of ammonium lauryl sulfate aqueous solution (water content 30%), grind until the solution becomes a gel, transfer to a crucible at 700 ° C for constant temperature roasting for 60 min to obtain fluffy La 2 O 2 SO 4 . Its X-ray diffraction analysis spectrum is as follows figure 1 (Example 1). After XRD, low temperature N 2 Adsorption, TPR, TPO test, the grain size is 10.3nm, the specific surface area is 14.3m 2 / g, the pore size distribution is 7~35nm, the reduction temperature is 843℃, and the oxidation temperature is 372℃.

Embodiment 2

[0021] Weigh 8.54g La (NO 3 ) 3 ·6H 2 O and 2.12g Ce (NO 3 ) 3 ·6H 2 O was placed in an agate mortar and smashed and ground, added 7.33 g of aqueous solution of ammonium dodecyl sulfate (water content 30%), ground until the solution became a gel, transferred to a crucible at 700 ° C for constant temperature roasting for 30 min to obtain a fluffy ( La 0.8 Ce 0.2 ) 2 O 2 SO 4 . Its X-ray diffraction analysis spectrum is as follows figure 1 (Example 2). After XRD, low temperature N 2 Adsorption, TPR, TPO test, the grain size is 10.1nm, the specific surface area is 15.2m 2 / g, the pore size distribution is 7~35nm, the reduction temperature is 801℃, and the oxidation temperature is 370℃.

Embodiment 3

[0023] Weigh 8.54g La (NO 3 ) 3 ·6H 2 O and 2.12g Pr(NO 3 ) 3 ·6H2 O was placed in an agate mortar and smashed and ground, added 7.33g of aqueous ammonium dodecyl sulfate solution (30% water), ground until the solution became a gel, transferred to a crucible at 550 ° C for constant temperature roasting for 20 min to obtain a fluffy ( La 0.8 Pr 0.2 ) 2 O 2 SO 4 . Its X-ray diffraction analysis spectrum is as follows figure 1 (Example 3). After XRD, low temperature N 2 Adsorption, TPR, TPO test, the grain size is 8.1nm, and the specific surface area is 30.5m 2 / g, the pore size distribution is 5~30nm, the reduction temperature is 753℃, and the oxidation temperature is 377℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com