Rotating zirconium oxide target and preparation method thereof

A technology of zirconia and zirconia powder, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of sparking and ablation on the surface of zirconia target materials, and achieve the uniformity of the overall resistivity High, high powder utilization, easy mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the rotary zirconia target material of the present invention specifically comprises the following steps:

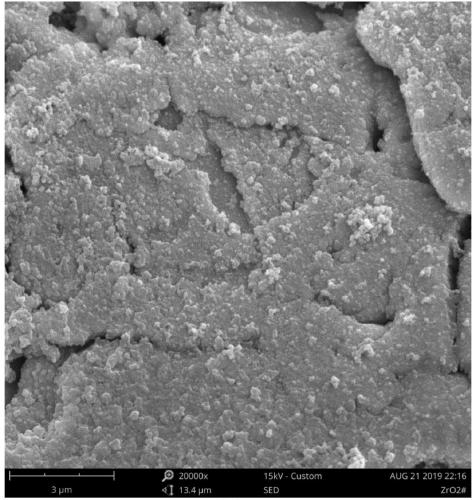

[0027] 1) Preparation of spray powder: select zirconia powder as the spray powder, and the D50 particle size of the zirconia powder is 20-70 μm, the purity is ≥99.5%, and the oxygen loss is ≥0.3wt%;

[0028] 2) Prepare the base tube: choose 304 non-magnetic stainless steel tube as the target base tube, use cast steel grit to sandblast the surface of the base tube, and then use copper-nickel wire or nickel-aluminum wire for arc priming, after priming treatment The surface roughness Ra of the substrate tube is 200-500μm;

[0029] 3) Plasma spraying: Install the base tube of the target material after primer treatment on the transmission equipment, and make it rotate around the central axis and move back and forth in the horizontal direction after passing hot water at 70-95 °C, and keep the spray gun fixed. When the surface temperature of the...

Embodiment 1

[0034] In this example, a zirconia target material with a thickness of 3 mm is prepared on 304 stainless steel, and the preparation method is as follows:

[0035] 1) Preparation of zirconia powder: the particle size requirement of the powder is that D50 is 70 μm, the purity is 99.5%, and the oxygen loss is 0.3wt%;

[0036] 2) Prepare the base tube: select a 304 non-magnetic stainless steel tube with a specification of ID80*OD88*L1220mm as the target base tube, use cast steel sand to sandblast the surface of the base tube, and then use a nickel-aluminum wire arc to prime;

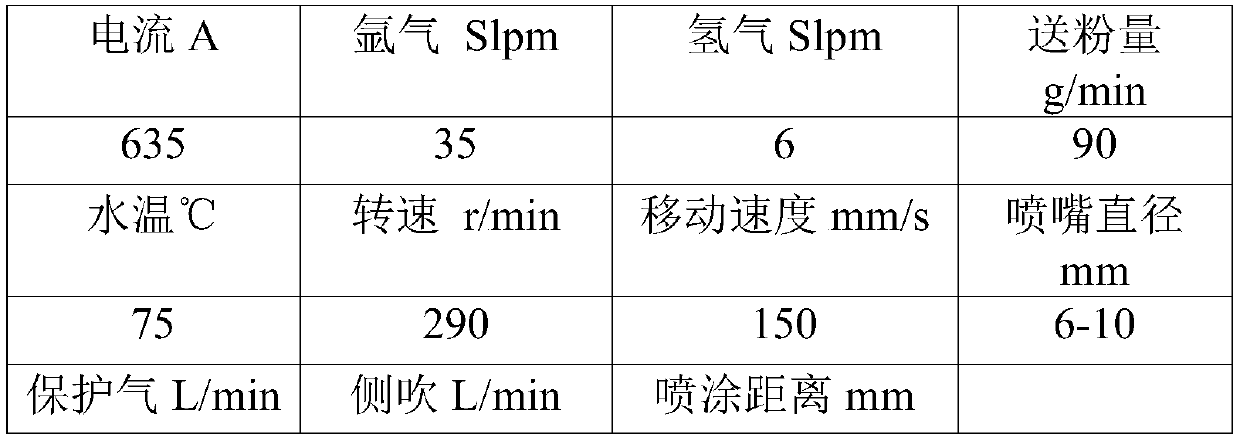

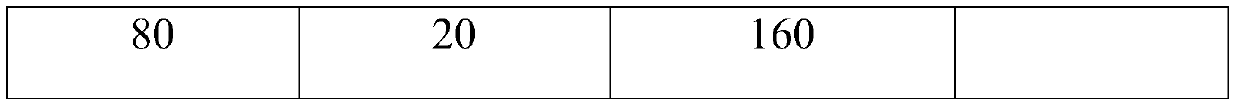

[0037] 3) Plasma spraying: Install the base tube of the target material after primer treatment on the transmission equipment, and make it rotate around the central axis and move back and forth in the horizontal direction after being passed through the water, and the spray gun remains fixed. When the surface temperature of the substrate tube reaches above 40°C, the spray gun is ignited, and at the same time, ...

Embodiment 2

[0044] In this example, a zirconia target material with a thickness of 3.5mm is prepared on 304 stainless steel, and the preparation method is as follows:

[0045] 1) Preparation of zirconia powder: the particle size requirement of the powder is that D50 is 70 μm, the purity is 99.5%, and the oxygen loss is 0.35wt%;

[0046] 2) Prepare the base tube: select a 304 non-magnetic stainless steel tube with a specification of ID80*OD88*L1500mm as the target base tube, use cast steel sand to sandblast the surface of the base tube, and then use a nickel-aluminum wire arc to prime;

[0047] 3) Plasma spraying: Install the base tube of the target material after primer treatment on the transmission equipment, and make it rotate around the central axis and move back and forth in the horizontal direction after being passed through the water, and the spray gun remains fixed. When the surface temperature of the substrate tube reaches above 40°C, the spray gun is ignited, and at the same time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com