Low-melting-point metal shaped phase-change material and preparation method thereof

A low-melting-point metal and phase-change material technology, applied in the field of materials, can solve the problems of easy deformation of low-melting point metals, high cost of shaped carriers, and difficult processing, etc., to improve wettability and affinity, increase flexibility and application range, the effect of reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

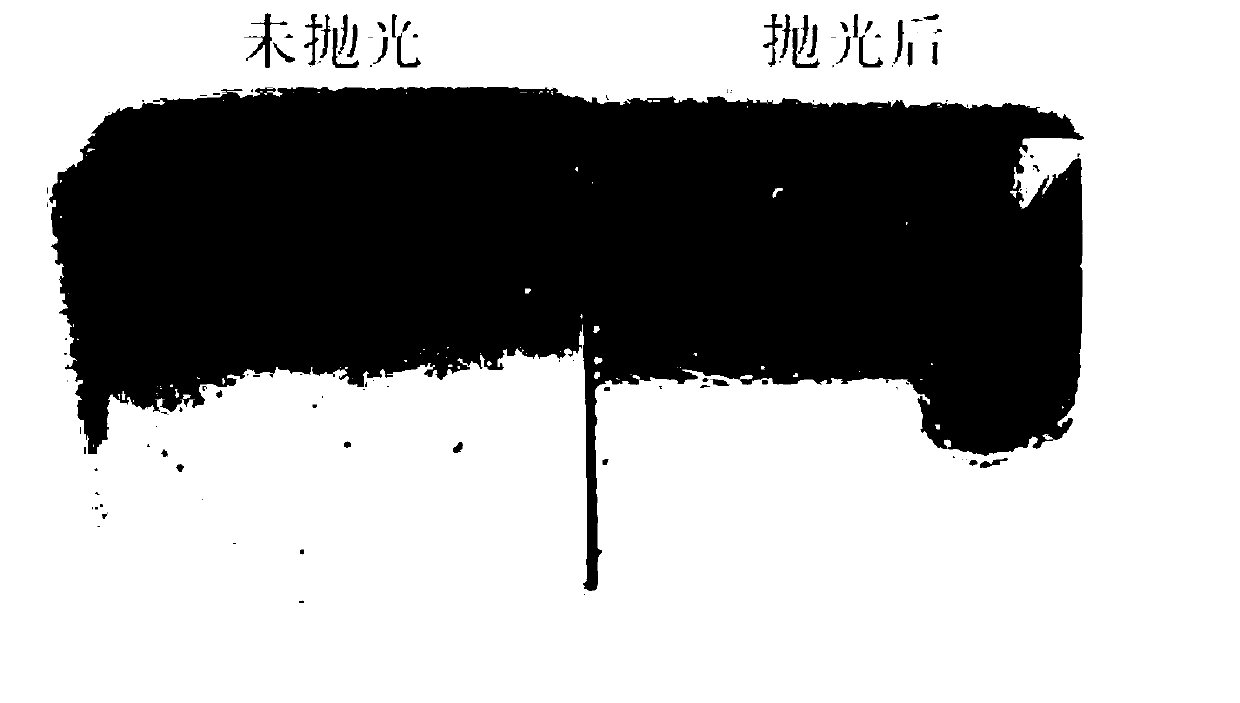

Image

Examples

Embodiment 1

[0066] A preparation method of a low-melting-point metal shaped phase-change material, comprising the steps of:

[0067] 30g mass fraction of 1% graphene oxide dispersion (wherein: the thermally conductive material is graphene oxide, the solvent is a mixture of ethanol and water, and the mass ratio of ethanol and water in the solvent is 1:1) is packed in a 50mL container In a beaker, immerse a piece of polystyrene foam (2cm×2cm×2mm) in the dispersion liquid, and press it with an iron block to prevent it from floating up; put the beaker in a vacuum oven, vacuumize for 5min, then open the valve and resume pressure, so that the graphene oxide dispersion fully enters the polystyrene foam; when the air pressure in the vacuum oven returns to normal atmospheric pressure, the foam is taken out from the beaker, placed in a 60°C oven for drying, and the graphene oxide is deposited on the polystyrene foam. On the pore wall inside the foam; repeat the above dipping deposition step 1 time ...

Embodiment 2

[0075] A preparation method of a low-melting-point metal shaped phase-change material, comprising the steps of:

[0076] 100g mass fraction of 1% graphene oxide aqueous dispersion (wherein: the thermal conductive material is graphene oxide, and the solvent is water) is packed in a plastic cup with a volume of 200mL, and a piece of melamine foam (cube) with a side length of 2cm ) was submerged in the dispersion, and pressed with an iron block to prevent it from floating; put the plastic cup into a vacuum oven, evacuate for 30 minutes, then open the valve and pressurize again, so that the graphene oxide water dispersion fully entered the foam; when the vacuum oven After the air pressure inside returned to normal atmospheric pressure, the foam was taken out from the plastic cup, placed in an oven at 80°C for drying, so that graphene oxide was deposited on the pore walls inside the foam; the above dipping and deposition steps were repeated twice to obtain a composite Foam; heat-tr...

Embodiment 3

[0086] 500g of aqueous dispersion containing 0.5wt.% graphene oxide and 1wt.% multi-walled carbon nanotubes (wherein: the heat-conducting material is graphene oxide and multi-walled carbon nanotubes, and the solvent is water) is contained in a plastic container with a volume of 1L In the box, 100 pieces of melamine foam (cubes) with a side length of 6mm are immersed in the dispersion liquid, and fastened with wire mesh to prevent floating; put the plastic box in a vacuum oven, vacuumize for 10min, and then open the valve to repress, so that The dispersion liquid fully enters the foam; when the air pressure in the vacuum oven returns to normal atmospheric pressure, take the foam out of the plastic box and place it in an oven at 80°C for drying, so that graphene oxide and carbon nanotubes are deposited in the pores inside the foam On the wall, syntactic foam is made.

[0087] Put 800g of lead-bismuth alloy with a melting point of 50°C into a plastic box, and heat in a blast oven a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com