Epoxy resin pouring sealant, preparation method thereof, and novel electric driven motor

An electric drive motor, epoxy resin technology, used in epoxy resin glue, manufacturing motor generators, electric components, etc., can solve the problems of the drive system not working properly, the drive motor burning, component failure, etc., to achieve the potting operation. The effect of low temperature, extended service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

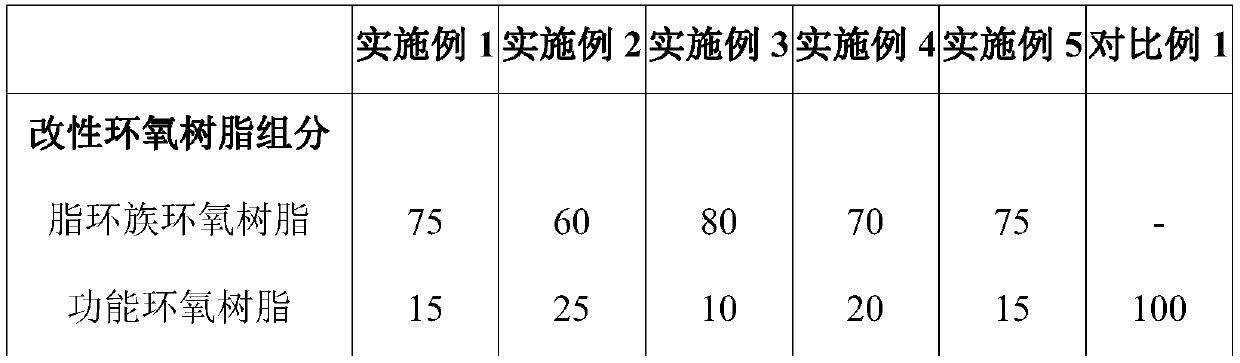

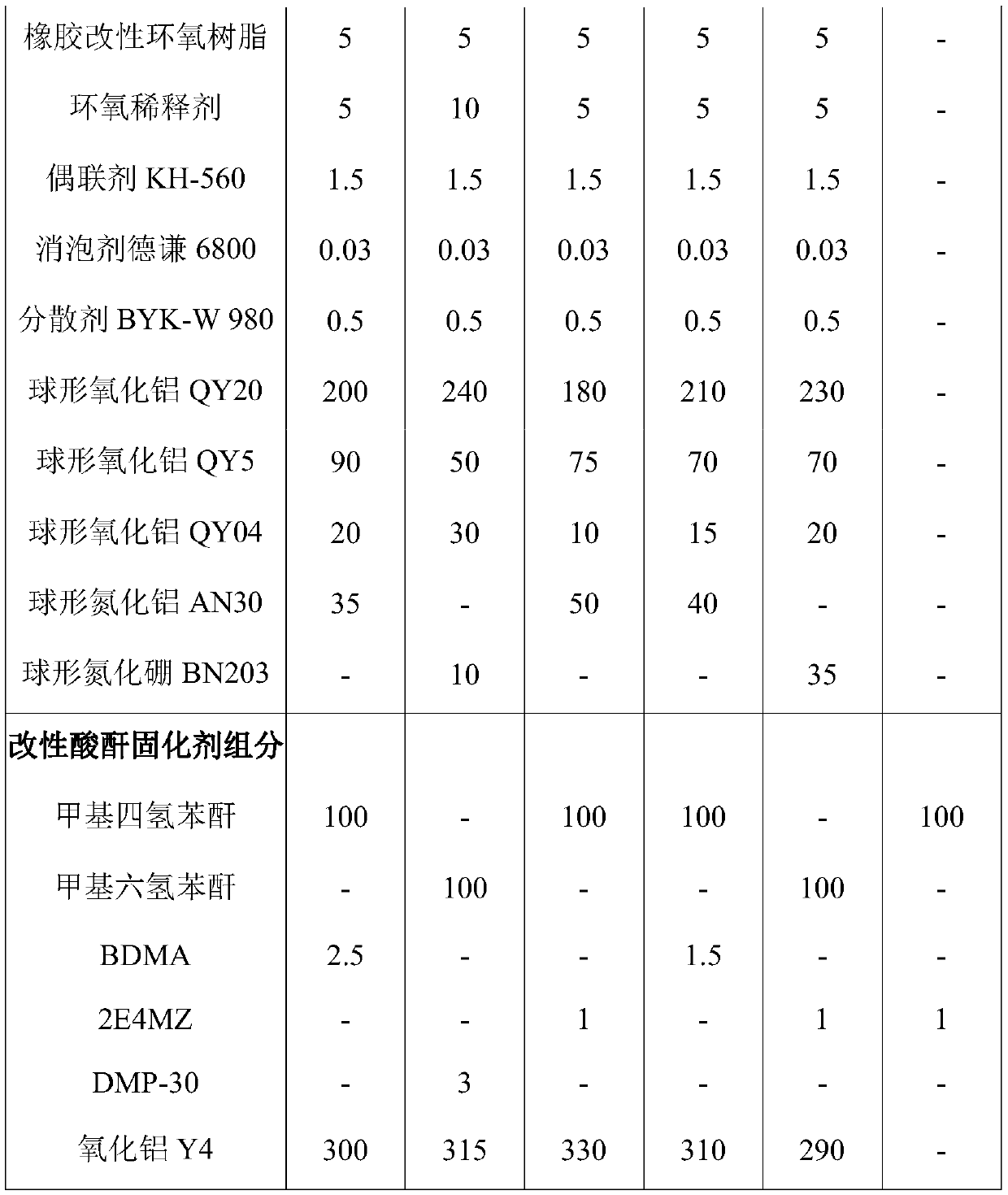

Embodiment 1

[0051] Preparation of modified epoxy resin: 75 parts of cycloaliphatic epoxy resin (1,3-bis(N,N-diglycidylaminomethyl)cyclohexane, Nantong Xinnaxi New Material Co., Ltd., S- 610), 15 parts of bisphenol A epoxy resin (Guodu Chemical (Kunshan) Co., Ltd., YD-127), 5 parts of core-shell structure rubber modified epoxy resin (Dalian Liansheng Trading Co., Ltd. / Japan KANEKA company, MX-154) and 5 parts of epoxy diluent (p-tert-butylphenyl glycidyl ether, Anhui Xinyuan Technology Co., Ltd., XY-693) were put into the stirring container, started stirring, stirring and mixing at room temperature for 10 minutes to a homogeneous liquid; Then add 1.5 parts of silane coupling agent (Yangzhou Wanhe Chemical Co., Ltd., KH-560), 0.03 parts of silicone defoamer (Deqian Chemical, Defom 6800), 0.5 parts of dispersant (Byk Chemicals, BYK-W 980), stirring for 10 minutes; finally, 200 parts of large particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY20, average partic...

Embodiment 2

[0055] Preparation of modified epoxy resin: 60 parts of cycloaliphatic epoxy resin (1,2-cyclohexanedicarboxylate diglycidyl, Nantong Xin Naxi New Materials Co., Ltd., S-184), 25 parts of bisphenol F-type epoxy resin (Guodu Chemical (Kunshan) Co., Ltd., YDF-170), 5 parts of core-shell structure rubber modified epoxy resin (Dalian Liansheng Trading Co., Ltd. / Japan KANEKA company, MX-154) and 10 parts Epoxy diluent (1,4-butanediol diglycidyl ether, Anhui Xinyuan Technology Co., Ltd., XY-622) was put into the mixing container, started stirring, stirring and mixing at room temperature for 10 minutes to a homogeneous liquid; then added 1.5 parts in sequence Silane coupling agent (Yangzhou Wanhe Chemical Co., Ltd., KH-560), 0.03 part of silicone defoamer (Deqian Chemical, Defom 6800), 0.5 part of dispersant (Byk Chemical, BYK-W 980), stirring for 10 minutes ; Add 240 parts of large particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY20, average particle...

Embodiment 3

[0059] Preparation of modified epoxy resin: 80 parts of cycloaliphatic epoxy resin (bis((3,4-epoxycyclohexyl) methyl) adipate, Nantong Xinnaxi New Material Co., Ltd., S-28 ), 10 parts of phenol novolac epoxy resin (Guodu Chemical (Kunshan) Co., Ltd., YDPN-631), 5 parts of core-shell structure rubber modified epoxy resin (Dalian Liansheng Trading Co., Ltd. / Japan KANEKA company, MX- 154) and 5 parts of epoxy diluent (benzyl glycidyl ether, Anhui Xinyuan Technology Co., Ltd., XY-692) into the stirring container, start stirring, stirring and mixing at room temperature for 10 minutes to a homogeneous liquid; then add 1.5 parts of silane in sequence Coupling agent (Yangzhou Wanhe Chemical Co., Ltd., KH-560), 0.03 part of silicone defoamer (Deqian Chemical, Defom 6800), 0.5 part of dispersant (Byk Chemical, BYK-W 980), stirring for 10 minutes; Finally, 180 parts of large particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY20, average particle size (D50)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com