Salt-corrosion-resistant torsion-resistant control cable for offshore wind power and manufacturing method thereof

A technology for controlling cables and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, insulating cables, and conductor/cable insulation, etc., which can solve the problem of not having the performance of seawater salt resistance, resistance to seawater moisture and immersion, unsuitable for marine wind power environment, and unfavorable for cables. Solve problems such as terminal insulation and sheath separation, to achieve the effect of enhancing impregnation against moisture, facilitating continuous transfer, and eliminating voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

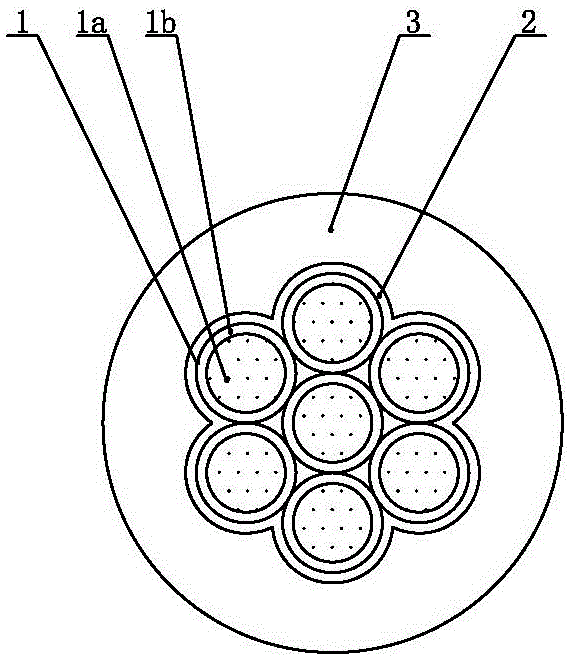

[0023] Such as figure 1 As shown, the salt-corrosion-resistant torsion-resistant control cable for marine wind power of the present invention sequentially includes the following steps: uniformly extruding a salt-corrosion-resistant torsion-resistant rubber insulation layer 1b on the outer periphery of the stranded copper conductor 1a to form the control cable insulated core 1, A plurality of control cable insulated cores 1 are twisted to form a control cable core, a low-strength non-woven longitudinal cladding 2 is longitudinally wrapped around the outer periphery of the control cable core, and a low-strength non-woven longitudinal cladding 2 is extruded on the outer periphery The sheath 3 tightly squeezes the longitudinal sheath 2 of low-strength non-woven fabric on the insulated core 1 of the control cable. The thickness of the longitudinal cladding layer 2 of the low-strength non-woven fabric is 0.05 mm, and the longitudinal cladding is successively overlapped along the axis ...

Embodiment 2

[0028] Such as figure 1 As shown, the salt-corrosion-resistant torsion-resistant control cable for marine wind power of the present invention sequentially includes the following steps: uniformly extruding a salt-corrosion-resistant torsion-resistant rubber insulation layer 1b on the outer periphery of the stranded copper conductor 1a to form the control cable insulated core 1, A plurality of control cable insulated cores 1 are twisted to form a control cable core, a low-strength non-woven longitudinal cladding 2 is longitudinally wrapped around the outer periphery of the control cable core, and a low-strength non-woven longitudinal cladding 2 is extruded on the outer periphery The sheath 3 tightly squeezes the longitudinal sheath 2 of low-strength non-woven fabric on the insulated core 1 of the control cable. The thickness of the longitudinal cladding layer 2 of the low-strength non-woven fabric is 0.08mm, and the longitudinal cladding is successively overlapped along the axis d...

Embodiment 3

[0033] Such as figure 1 As shown, the salt-corrosion-resistant torsion-resistant control cable for marine wind power of the present invention sequentially includes the following steps: uniformly extruding a salt-corrosion-resistant torsion-resistant rubber insulation layer 1b on the outer periphery of the stranded copper conductor 1a to form the control cable insulated core 1, A plurality of control cable insulated cores 1 are twisted to form a control cable core, a low-strength non-woven longitudinal cladding 2 is longitudinally wrapped around the outer periphery of the control cable core, and a low-strength non-woven longitudinal cladding 2 is extruded on the outer periphery The sheath 3 tightly squeezes the longitudinal sheath 2 of low-strength non-woven fabric on the insulated core 1 of the control cable. The thickness of the longitudinal cladding layer 2 of the low-strength non-woven fabric is 0.1mm, and the longitudinal cladding is successively overlapped along the axis di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com