Manufacturing method of electrolytic copper foil for lithium ion secondary battery

A secondary battery and electrolytic copper foil technology, applied in the electrolysis process, electroforming, etc., can solve the problems of inability to adjust the properties of copper foil, cumbersome switching of copper foil, and differences, and achieve the effect of stable and easy-to-control brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

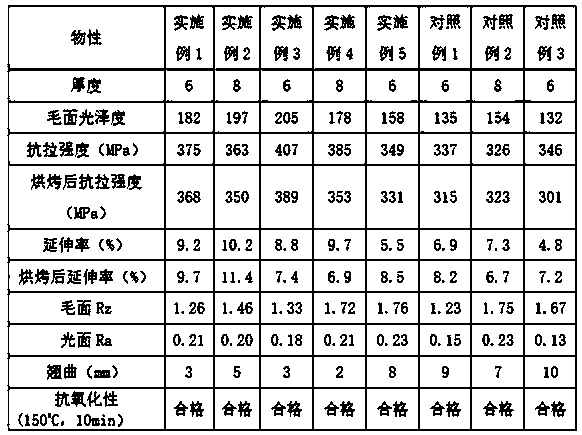

Examples

Embodiment 1

[0032] Put the clean copper rod or copper plate into the copper-dissolving tank containing sulfuric acid, control the temperature, at about 85°C, blow air in with a screw fan, and dissolve the copper to prepare the main electrolyte.

[0033] The main electrolyte is mixed with the additive solution after multi-stage filtration to obtain the electrolyte. The copper ion concentration of the electrolyte is 82g / L, the sulfuric acid content is 103g / L, and the chloride ion concentration is 20mg / L.

[0034] The additive composition and concentration are:

[0035] Dosage 01: sodium polydithiodipropane sulfonate 10mg / L;

[0036] Two doses are used for 02: collagen (average molecular weight 3000-5000) 10mg / L and polyether ammonia 5mg / L;

[0037] 03 doses: polyethylene glycol (average molecular weight 6000) 5mg / L;

[0038] Dosage 04: Hydroxyethylcellulose (viscosity 300) 10mg / L.

[0039] The above electrolytic solution is heated to 45°C through the heat exchanger, and then poured into ...

Embodiment 2

[0041] Put the clean copper rod or copper plate into the copper-dissolving tank containing sulfuric acid, control the temperature, at about 85°C, blow air in with a screw fan, and dissolve the copper to prepare the main electrolyte.

[0042] The main electrolyte is mixed with the additive solution after multi-stage filtration to obtain an electrolyte. The electrolyte has a copper ion concentration of 90 / L, a sulfuric acid content of 100 g / L, and a chloride ion concentration of 25 mg / L.

[0043] The additive composition and concentration are:

[0044] Agent 01: sodium polydisulfide dipropane sulfonate: 14mg / L;

[0045] Dosage 02: polyethyleneimine (average molecular weight 1200): 5mg / L;

[0046] Dosage 03: polyethylene glycol (average molecular weight 6000) 7mg / L;

[0047] Dosage 04: Hydroxyethylcellulose (viscosity 400) 20mg / L.

[0048] The above electrolytic solution is heated to 55°C through a heat exchanger, and then poured into the electrolytic cell, at 50A / dm 2 Under ...

Embodiment 3

[0050] Put the clean copper rod or copper plate into the copper-dissolving tank containing sulfuric acid, control the temperature, at about 85°C, blow air in with a screw fan, and dissolve the copper to prepare the main electrolyte.

[0051] The main electrolyte is mixed with the additive solution after multi-stage filtration to obtain an electrolyte. The electrolyte has a copper ion concentration of 85g / L, an acid content of 105g / L, and a chloride ion concentration of 28mg / L.

[0052] The additive composition and concentration are:

[0053] 01 agent: N,N-Dimethyldithioformamide propane sulfonate sodium 20mg / L;

[0054] 02 doses: collagen (average molecular weight 3000-5000) 10mg / L;

[0055] Dosage 03: polyethylene glycol (average molecular weight 6000) 7mg / L;

[0056] Dosage 04: Hydroxyethylcellulose (viscosity 380): 30mg / L.

[0057] The above electrolytic solution is heat exchanged to 50 o C, into the electrolyzer, at 45A / dm 2 Under the current density, keep the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com