Quick-setting polymer latex waterproof coating

A technology of polymer emulsion and waterproof coating, applied in the direction of coating, can solve the problem of long setting time and achieve the effect of fast setting time, easy preparation and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

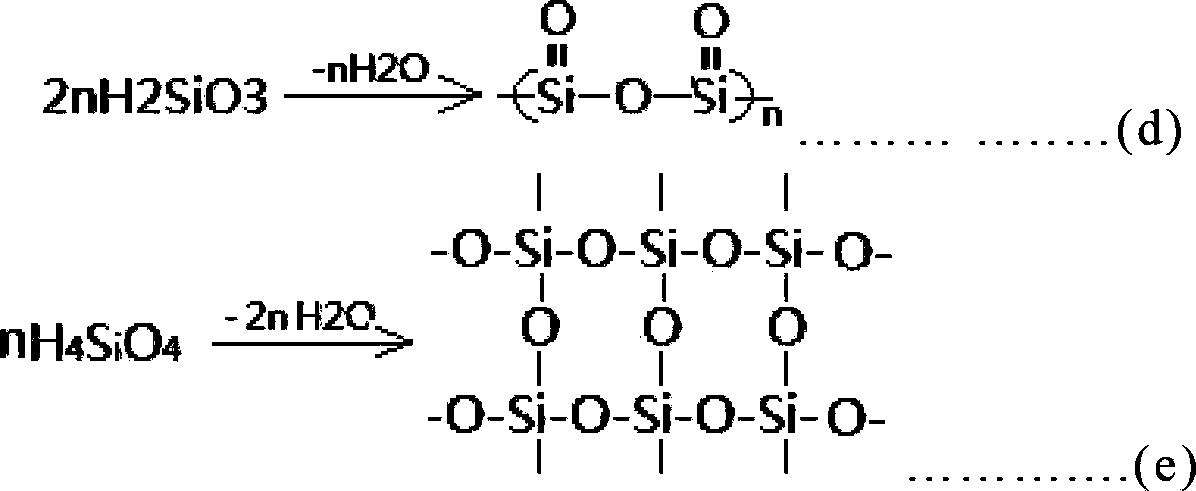

Method used

Image

Examples

Embodiment 1

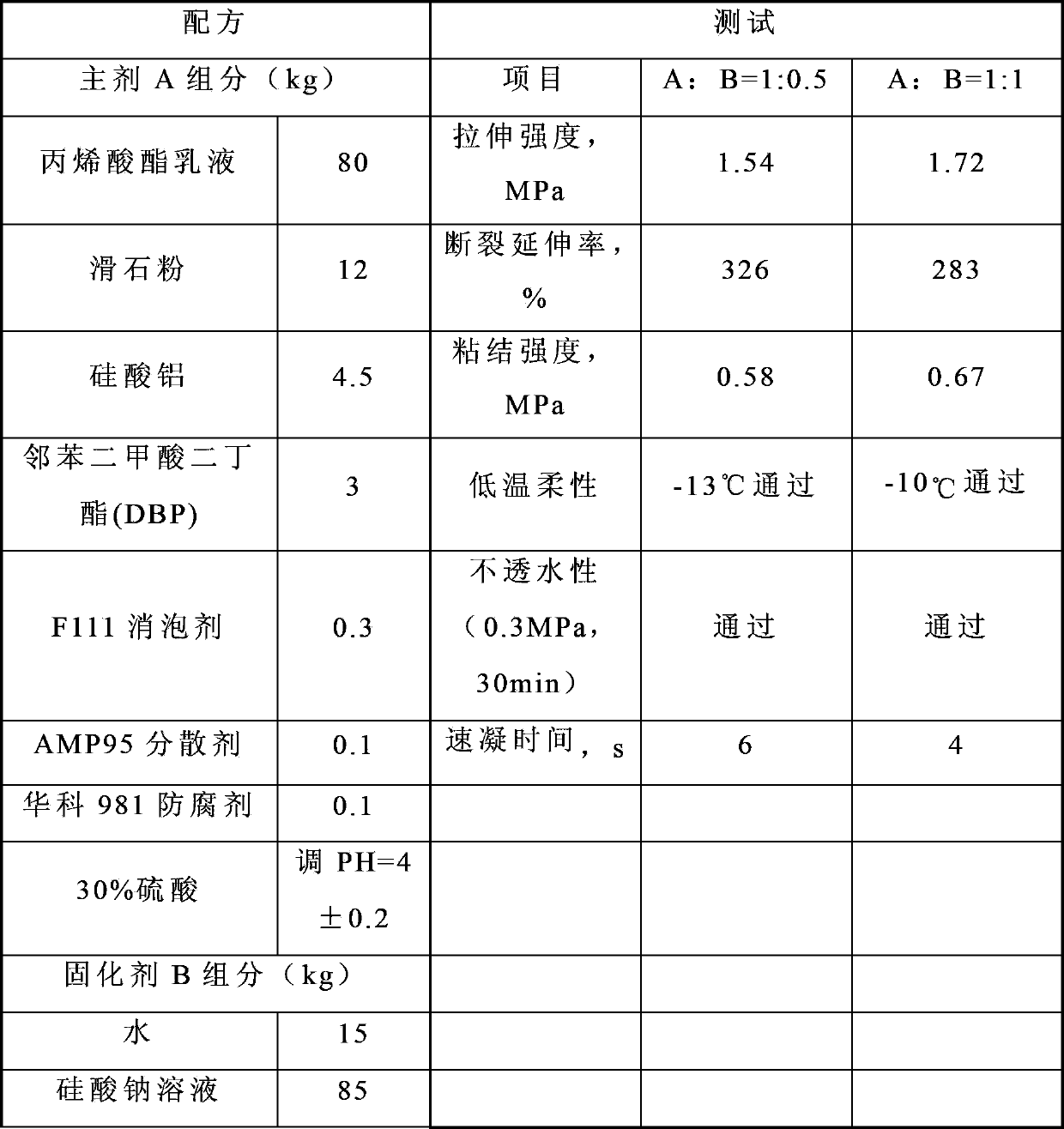

[0041] A quick-setting polymer emulsion waterproof coating, comprising main agent A component and curing agent B component, the composition of the main agent A component and curing agent B component is shown in the following table 1, and at the same time, the main agent A Components and curing agent B components are sprayed to form films according to the mass ratio of 1:0.5 and 1:1; the quick-setting time is the time when the coating is sprayed to the mortar test block at a horizontal 45° angle, from A and B contacting to non-flowing time , and other indicators are tested according to GB / T23445-2009, and are listed in Table 1 below.

[0042] The formula and test result of table 1 embodiment one

[0043]

[0044] The preparation method of above-mentioned building waterproof paint, comprises the steps:

[0045] (1) Preparation of component B of curing agent: mix sodium silicate solution (42Be, 2.5 molds) and water component according to the ratio in Table 1, and stir evenly;...

Embodiment 2

[0048]A quick-setting polymer emulsion waterproof coating, including main agent A component and curing agent B component, the composition of the main agent A component and curing agent B component is shown in the following table 2, and at the same time, the main agent A Components and curing agent B components are sprayed to form films according to the mass ratio of 1:0.5 and 1:1; the quick-setting time is the time when the coating is sprayed to the mortar test block at a horizontal 45° angle, from A and B contacting to non-flowing time , and other indicators are tested according to GB / T23445-2009, and are listed in Table 2 below.

[0049] The formula and test result of table 2 embodiment two

[0050]

Embodiment 3

[0052] A quick-setting polymer emulsion waterproof coating, comprising main agent A component and curing agent B component, the composition of the main agent A component and curing agent B component is shown in the following table 3, and at the same time, the main agent A Components and curing agent B components are sprayed to form films according to the mass ratio of 1:0.5 and 1:1; the quick-setting time is the time when the coating is sprayed to the mortar test block at a horizontal 45° angle, from A and B contacting to non-flowing time , and other indicators are tested according to GB / T23445-2009, and are listed in Table 3 below.

[0053] The formula and test result of table 3 embodiment three

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com